952

How to make DVD-discs (30 photos)

Photographer Andrew Manuilov was sure that the information on any drive is always recorded. As it turns out, no. Once on a single plant in Kazakhstan for production of optical media LaserMaster, he learned that the information on the disc is literally imprinted. But see for yourself

Production CD - process is fully automated, but watching him chief engineer Sergey Votintsev

Optical discs are made of polycarbonate, which is supplied to the factory in huge sacks

That is - the future drives!

Bags of pellets go first in the drying device ...

after which the tubes are directed into the molding machine where it is heated to a liquid state ...

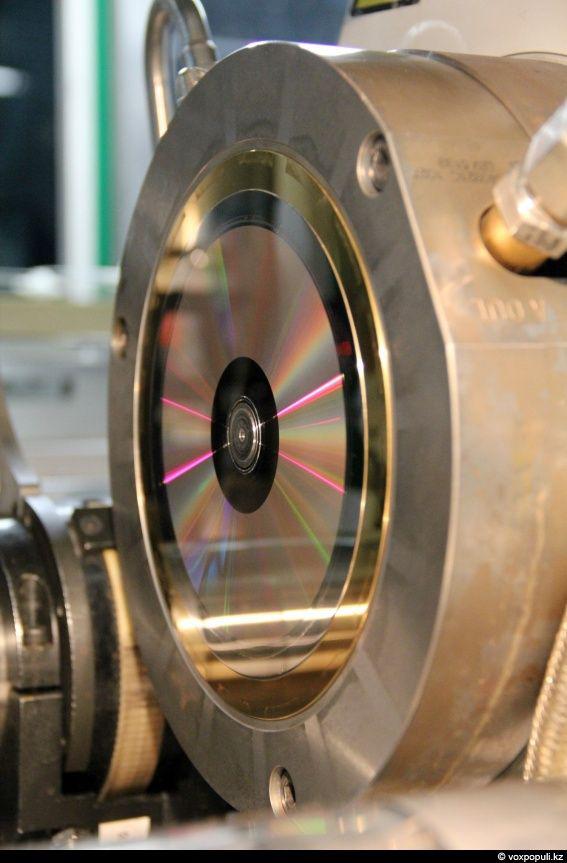

... And injected under pressure into a mold in which the stamper is

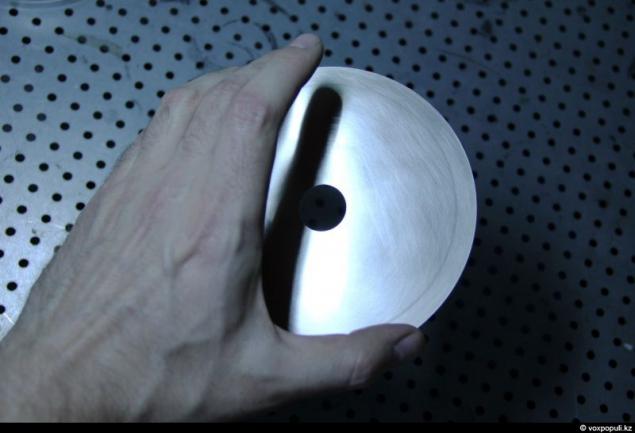

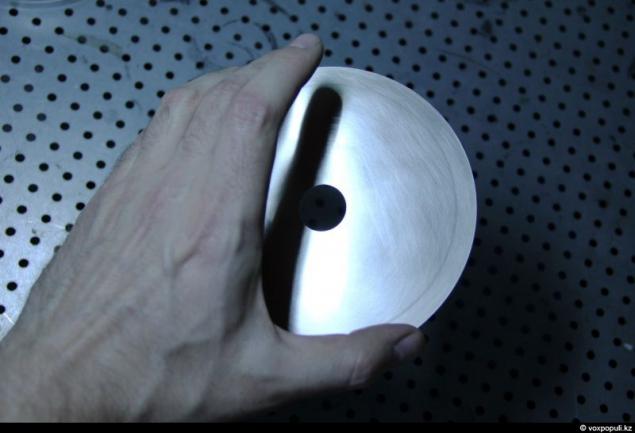

Stamper - a metal plate with the exact image information. Here in this thing, and is a film that later transferred to the disk. We stamper has another name - matrix. By the way, no one would have allowed you so simply take the matrix in the hands - I think that it immediately end

At a temperature of 250 degrees is heated to liquid state polycarbonate, takes the form of a disc. And the information applied to the matrix is imprinted on it

The first 30 pieces each draw automatically reject to ensure the stability of subsequent casting

The blanks with information received in the cooling unit where their temperature falls to room

Then they are covered by a reflective surface (metallization) so that later laser beam in your player can read the information on the disk. Without this coating laser simply pass through

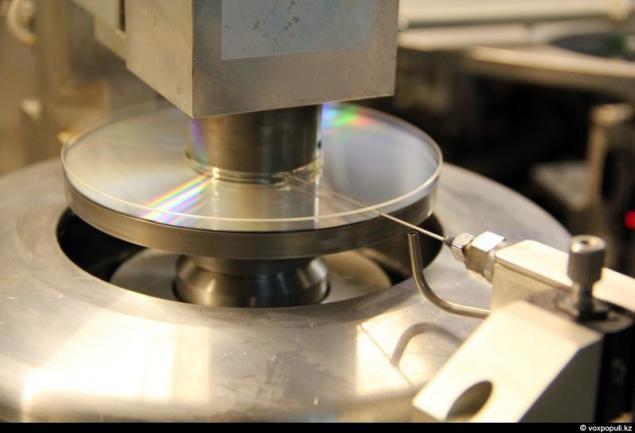

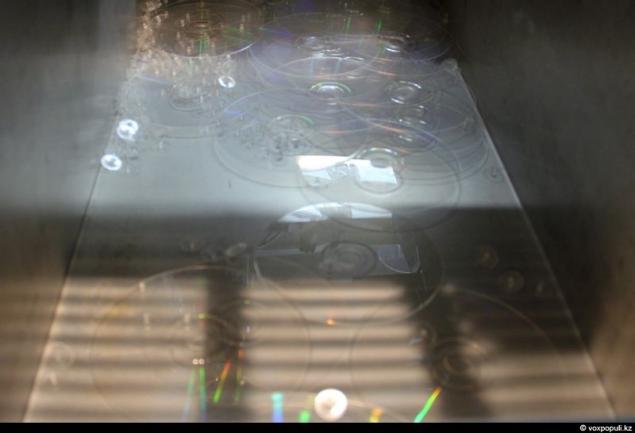

Then blanks are glued together by a transparent glue that is unwound over the surface of the centrifuge for uniform gluing. DVD-wheels consist of two layers, a CD - one

While this is a semi-products

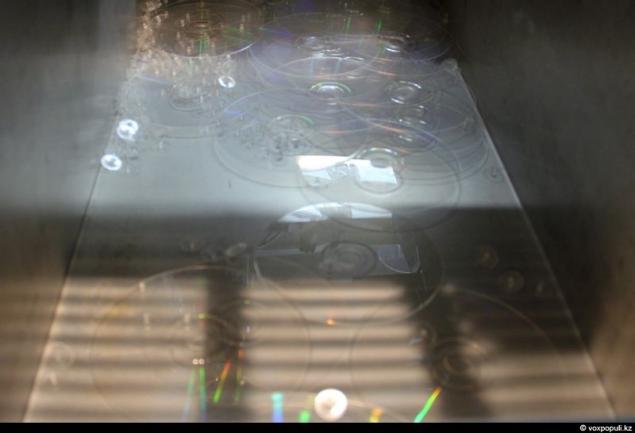

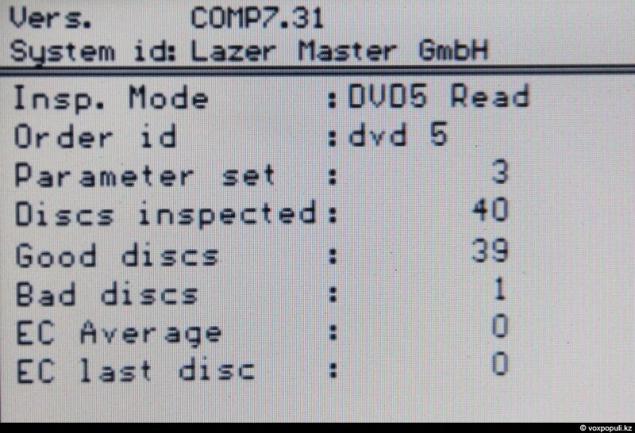

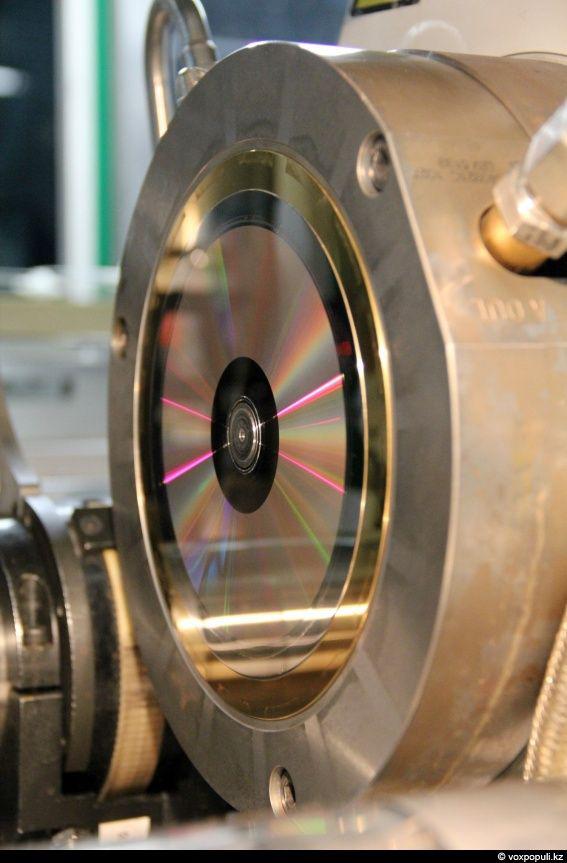

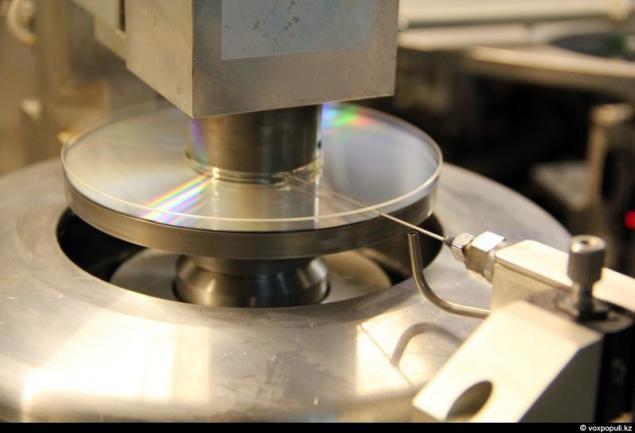

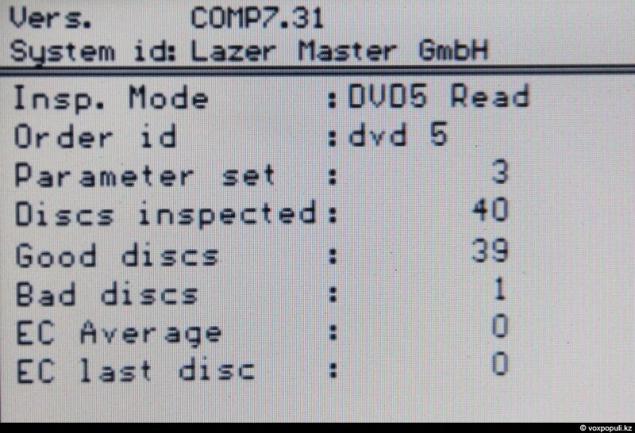

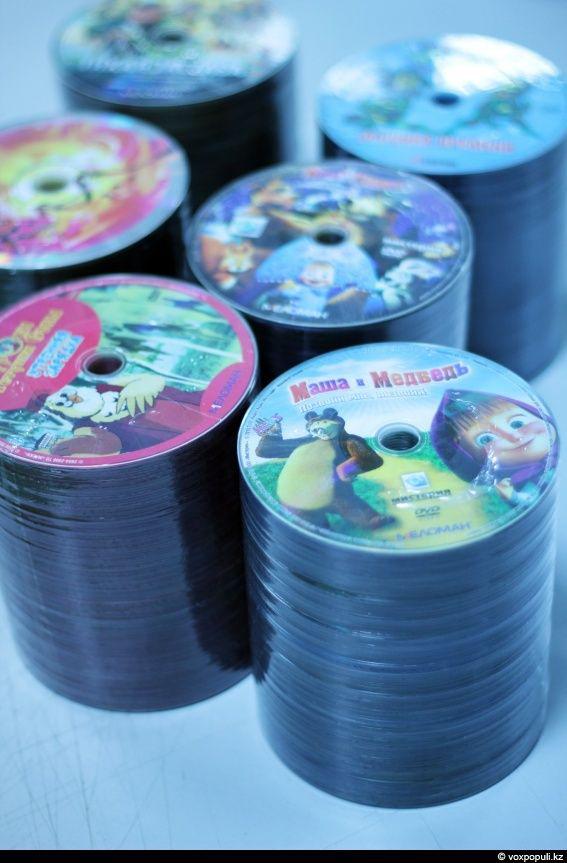

Disk surface test is performed with a laser. Of the 40 drives the car has rejected one. Minimum party of one of the film - 500 discs. Manufacturing period of 14 days, the capacity of the plant is 300,000 discs per month

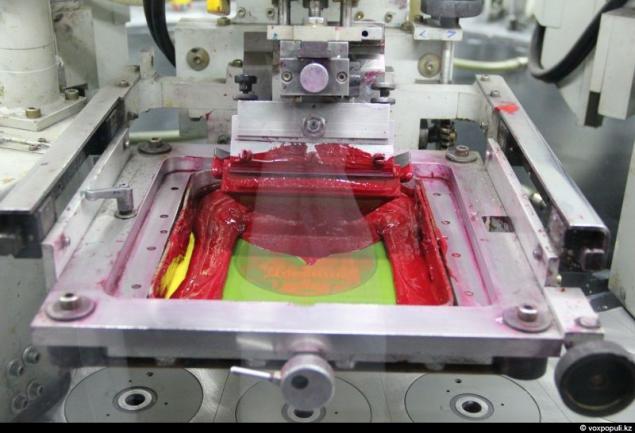

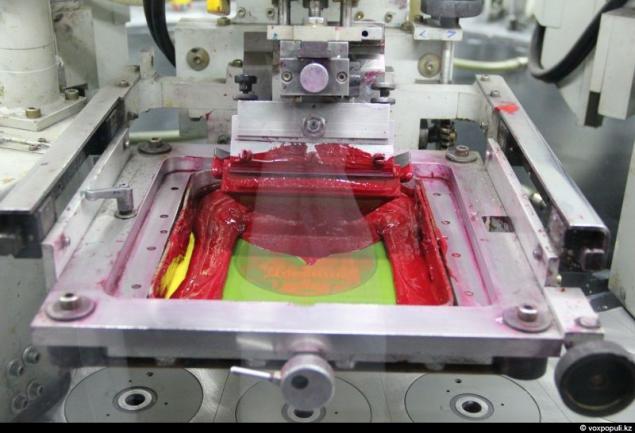

Once printed one batch of films, it is sent to the painting. At this time, you can run another batch of films

This process next novel Gordeev, the operator of the printer, whose mission - to achieve an exact match of the customer received the label layout

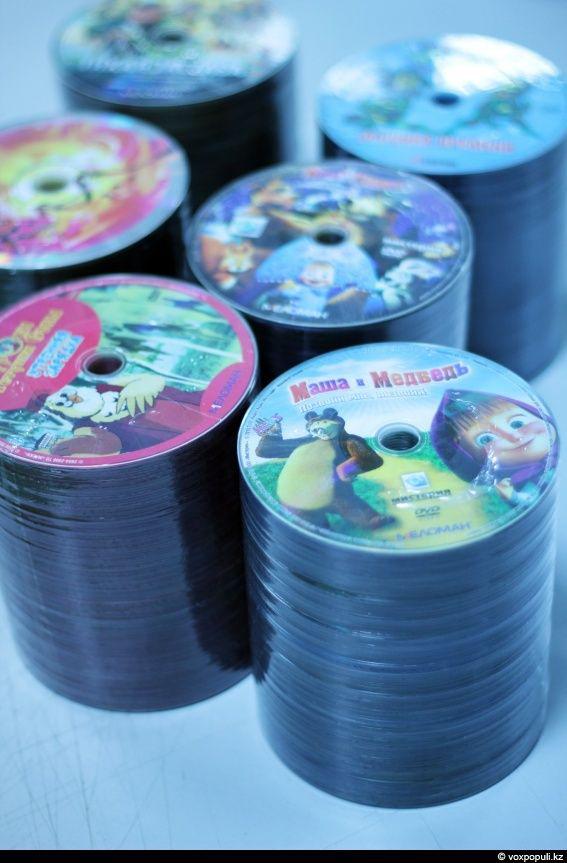

Ready drives come in a temporary warehouse, where all are in alphabetical order.

Irina, accounting manager, prepares a complete set with the task - and printing discs for subsequent assembly

Each disc is accompanied by a hologram

First, a DVD-box printing is inserted, then the disk. Girls do it with incredible speed

Collected wheels fall on the machine where packed in cellophane film

And only then collected in boxes and sent to the distribution center

From there, the goods of daily expenses shop all over Kazakhstan

Now the boxes are shipped to the store "Grand listen to anything", located on Gogol Street Almaty

At all stages, made a careful control over the safety of all intellectual property from possible leaks

Happy viewing!

voxpopuli

Production CD - process is fully automated, but watching him chief engineer Sergey Votintsev

Optical discs are made of polycarbonate, which is supplied to the factory in huge sacks

That is - the future drives!

Bags of pellets go first in the drying device ...

after which the tubes are directed into the molding machine where it is heated to a liquid state ...

... And injected under pressure into a mold in which the stamper is

Stamper - a metal plate with the exact image information. Here in this thing, and is a film that later transferred to the disk. We stamper has another name - matrix. By the way, no one would have allowed you so simply take the matrix in the hands - I think that it immediately end

At a temperature of 250 degrees is heated to liquid state polycarbonate, takes the form of a disc. And the information applied to the matrix is imprinted on it

The first 30 pieces each draw automatically reject to ensure the stability of subsequent casting

The blanks with information received in the cooling unit where their temperature falls to room

Then they are covered by a reflective surface (metallization) so that later laser beam in your player can read the information on the disk. Without this coating laser simply pass through

Then blanks are glued together by a transparent glue that is unwound over the surface of the centrifuge for uniform gluing. DVD-wheels consist of two layers, a CD - one

While this is a semi-products

Disk surface test is performed with a laser. Of the 40 drives the car has rejected one. Minimum party of one of the film - 500 discs. Manufacturing period of 14 days, the capacity of the plant is 300,000 discs per month

Once printed one batch of films, it is sent to the painting. At this time, you can run another batch of films

This process next novel Gordeev, the operator of the printer, whose mission - to achieve an exact match of the customer received the label layout

Ready drives come in a temporary warehouse, where all are in alphabetical order.

Irina, accounting manager, prepares a complete set with the task - and printing discs for subsequent assembly

Each disc is accompanied by a hologram

First, a DVD-box printing is inserted, then the disk. Girls do it with incredible speed

Collected wheels fall on the machine where packed in cellophane film

And only then collected in boxes and sent to the distribution center

From there, the goods of daily expenses shop all over Kazakhstan

Now the boxes are shipped to the store "Grand listen to anything", located on Gogol Street Almaty

At all stages, made a careful control over the safety of all intellectual property from possible leaks

Happy viewing!

voxpopuli