1398

3D-printing opens the door for space colonization

Only in the Milky Way number of planets suitable for life, scientists estimated at 60 billion (according to the latest advanced estimates). It is clear that with modern engines flight will take millions of years, but in the long term decay Sun colonization of other planets in the M-Class seems the only possible through the development of civilization.

Anyway, before settling other systems to be good to master its own system: first, the Moon and Mars. Will create a permanent base. On мнению Professionals , a key technology in this way should be 3D-printing. With the help of 3D-printers and robots, we can create any objects on the lunar and Martian bases, successfully develop the colony, managing the process from the ground. With the help of 3D-printing, we may collect interstellar ships directly on the lunar and Martian bases, driving back supplies.

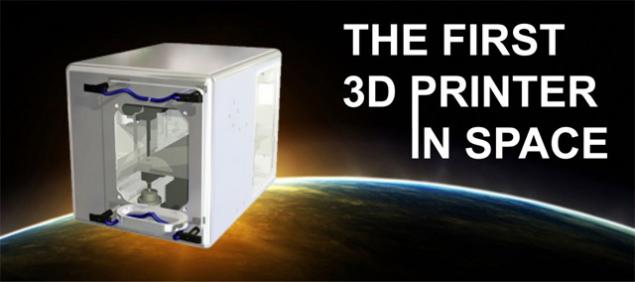

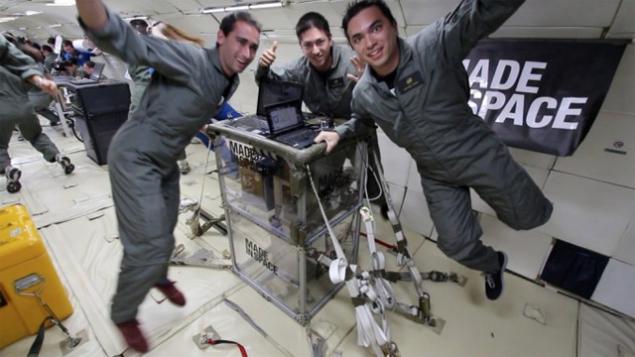

One way or another, but the 3D-printer - a key technology for the successful implementation of space programs, building bases and alien colonization of other worlds. One company that works in this area - Made In Space . Her goal - to develop a 3D-printer that works fine in microgravity on the International Space Station.

Cost of goods lifting from Earth orbit is estimated at approximately $ 22 thousand. Per kilogram. This is an acceptable cost for lifting the necessary building materials. If more will produce something with asteroids that brought into orbit , it will still be cheaper. And most importantly, that the materials for the production can be mined on the planet itself, which is set 3D-printer. Actually, not least for this reason Curiosity now conducting a thorough analysis of the soil of Mars.

"The structures for space flight at this time constructed on Earth - says Dan Barry, a former astronaut and consultant Made In Space, - so they have to withstand Earth's gravity, as well as vibration and overload, which is accompanied by the placing into orbit. If print structures in orbit the 3D-printer, they can be much more elegant, and in some cases, not so strong to withstand its own weight in the world, but still quite functional in microgravity. " 3D-press in orbit delivery only supplies anyway saves a lot of logistics and shipping costs.

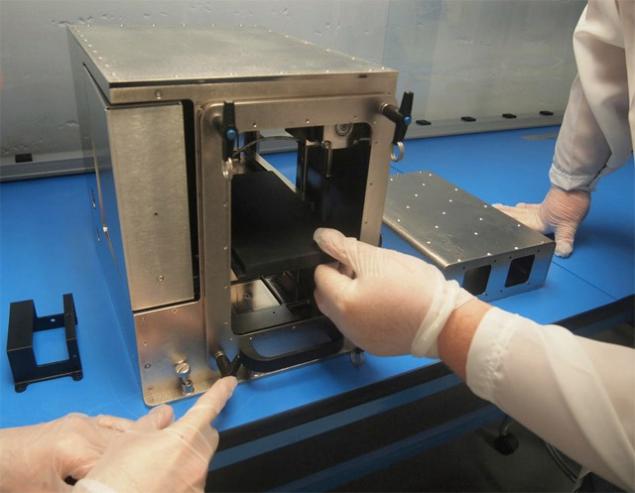

Starting next year, the company, in partnership with NASA will begin testing its 3D-printer directly to the ISS. It turned out that construct the printer working in zero gravity - not an easy task. This device must accept overload when starting on a rocket, it must be compact and safe, while working smoothly in microgravity. Company Made In Space tested dozens of popular models of 3D-printers, but none of them has not passed all the tests. So we had to design their own model.

Over the past year, this printer intensively tested in microgravity on Earth, and finally a group of engineers, NASA found him fit for trial on the ISS.

"Imagine the opportunity to colonize distant planet, bringing back only 3D-printer and some mining equipment. It seems like science fiction, but the first steps towards the implementation of such a plan we do in the lab right now, and next year will continue the ISS. Once we are able to extract useful resources from asteroids, planets and moons, we can use these resources to create large and complex structures that are capable of supporting human life. The main thing that we were able to build what it takes code doberёmsya there because it is too difficult to haul everything you need with you, "- said Mike Chen, director of strategic Made in Space, referring to the colonization of Mars, which is scheduled for the coming decades.

Design "space" Printer Made in Space will be open to all, so that anyone can offer appropriate facilities for printing in space and on the Martian base. The company invites all who have ideas that print to the ISS next year, write to the address info [at] madeinspace.us.

Source: habrahabr.ru/post/202070/

Motorola introduced the "low-cost alternative flagships": smartphone Moto G

At MIT have developed physically change the shape of the screen