541

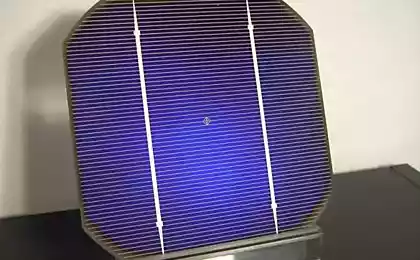

A new "electronic ink" will help to make solar panels incredibly cheap

Recently a team of researchers from the scientific and technical College from the University of Minnesota and the National renewable laboratory in Golden, Colorado, announced the development of "electronic ink", which will produce solar panels at a cost comparable to the price of conventional roofing shingles.

This material consists of nanocrystals of silicon, non – toxic substances, which can cover any inexpensive plastic substrate. Also, the "electronic ink" will help to reduce the cost of electronic touch panels.

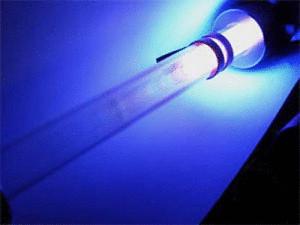

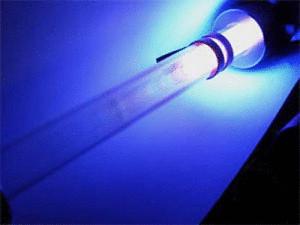

In order to create ink, which have a long shelf life and good electrical properties, scientists have developed a new method. For the production of silicon nanocrystals they used ionized gas, which is known as "nonthermal plasma". Then these particles they are coated with a layer of chlorine atoms.

Chlorine is necessary to "kick-starting" a chemical reaction in which the use of certain solvents and are formed of silicon ink. This new material does not need Soaps molecules ligands, which are used in most other silicon ink.

In addition, the new process allows you to add the silicon nanocrystals of various impurities that contribute to the increase of electronic conductivity. As a result, scientists have achieved that in the new material the velocity of the electrons 1000 times higher than in other comparable non-alloy coatings.

But the most important advantage of this technology is the possibility of manufacturing solar panels is almost as simple and easy as the production of inscriptions and of texts by screen printing. Thus, the new study will pave the way for creating cheaper renewable energy sources and mobile devices, which can be particularly useful for people living in developing countries that lack in electricity. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: www.ekopower.ru/?p=2125

This material consists of nanocrystals of silicon, non – toxic substances, which can cover any inexpensive plastic substrate. Also, the "electronic ink" will help to reduce the cost of electronic touch panels.

In order to create ink, which have a long shelf life and good electrical properties, scientists have developed a new method. For the production of silicon nanocrystals they used ionized gas, which is known as "nonthermal plasma". Then these particles they are coated with a layer of chlorine atoms.

Chlorine is necessary to "kick-starting" a chemical reaction in which the use of certain solvents and are formed of silicon ink. This new material does not need Soaps molecules ligands, which are used in most other silicon ink.

In addition, the new process allows you to add the silicon nanocrystals of various impurities that contribute to the increase of electronic conductivity. As a result, scientists have achieved that in the new material the velocity of the electrons 1000 times higher than in other comparable non-alloy coatings.

But the most important advantage of this technology is the possibility of manufacturing solar panels is almost as simple and easy as the production of inscriptions and of texts by screen printing. Thus, the new study will pave the way for creating cheaper renewable energy sources and mobile devices, which can be particularly useful for people living in developing countries that lack in electricity. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: www.ekopower.ru/?p=2125