678

At IBM Research have created a high-temperature self-healing gel

IBM Research team in Silicon Valley, USA, has announced a new discovery - self-healing organogels with unique capabilities. These gels solidify upon cooling, but with an increase in temperature returns to its original condition. The results of the scientists have already been published.

Applications of the gel sufficiently extensive, for example, such substances may be used in the industry. The gel can be poured into the mold, cool, and seeing that the resulting casting there is an error, you can repeat the process of "heating-cooling" to correct the defect.

What is a gel?

Gels (singular gel from Lat. Gelo - «stop the motion") - structured systems, consisting of high molecular weight and low molecular weight substances. The presence of three-dimensional polymer frame (mesh) gels according to the mechanical properties of solids: the absence of stress, the ability to maintain the shape, strength and deformability (ductility and elasticity). Gels consist of at least two components, one of which forms a continuous three-dimensional macromolecular keeper acting as a skeleton, in which the voids are filled with a low molecular weight solvent - the dispersion medium.

Gel volume can be compared with a fishing net, the cells of which are filled with fluid. At IBM Research added to the organogel molecules monomers. In an experiment conducted by scientists at the initial weight have been added and the molecule initiators that when exposed to UV radiation is converted monomers into polymers. Thus organogel created IBM, when exposed to UV light becomes hard as plastic.

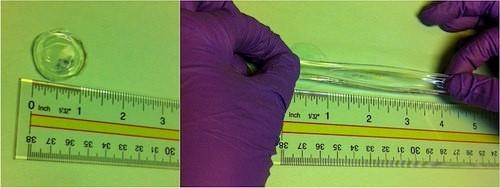

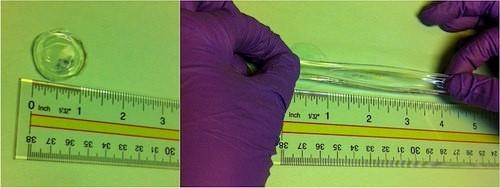

Demonstration elasticity organogel

After several tens of tests for measuring the hardness of the gel and determine the correct ratio of components, experts have created a modified gel that can be melted at temperatures above 80 degrees Celsius, and which recovers its properties when cooled to 20 degrees. The output scientists have gel (first kind) which can be melted and cooled without losing its unique qualities. Once the gel is formed from such a facility is the desired shape, the resulting object to the effects of UV radiation, which leads to the final hardening of the gel.

Such material may be used for filling cracks. Organogel - sufficient liquid material to penetrate without any problem in a small space, but it does not flow out of them. Exposure to UV radiation allows the material to harden, resulting in a full closing of cracks. In the future, such substances can be used for a 3D printer. However, many modern 3D printers are not perfect, because the layering material leads to a lack of structure and form. A new gel may be used to create almost ideal objects by changing the temperature and the level of UV radiation. According to experts, control the temperature of the gel gets rid of problems with the structure and appearance of the printed patterns.

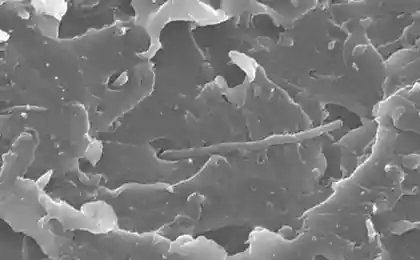

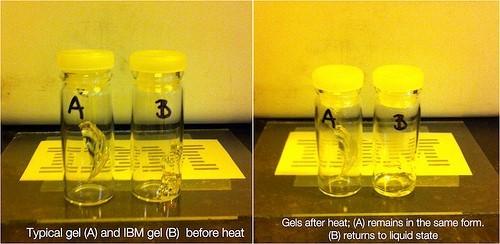

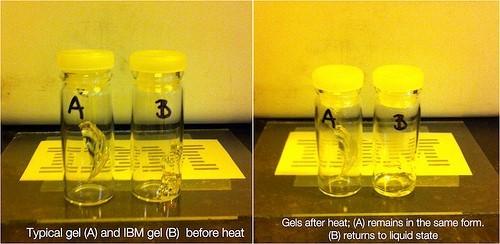

A - a conventional gel, B - gel created by IBM. On the left - the state of the gels under normal conditions, to the right - the same samples after heating

Continuity

The above gels were created using materials from the project two years ago IBM scientists Jim Hedrick and Jeannette Garcia. Then the scientists have developed a method for the synthesis of industrial polymers. Using the processes discussed in this material allowed to create organogels with the described properties.

Source: geektimes.ru/company/ibm/blog/268986/

Applications of the gel sufficiently extensive, for example, such substances may be used in the industry. The gel can be poured into the mold, cool, and seeing that the resulting casting there is an error, you can repeat the process of "heating-cooling" to correct the defect.

What is a gel?

Gels (singular gel from Lat. Gelo - «stop the motion") - structured systems, consisting of high molecular weight and low molecular weight substances. The presence of three-dimensional polymer frame (mesh) gels according to the mechanical properties of solids: the absence of stress, the ability to maintain the shape, strength and deformability (ductility and elasticity). Gels consist of at least two components, one of which forms a continuous three-dimensional macromolecular keeper acting as a skeleton, in which the voids are filled with a low molecular weight solvent - the dispersion medium.

Gel volume can be compared with a fishing net, the cells of which are filled with fluid. At IBM Research added to the organogel molecules monomers. In an experiment conducted by scientists at the initial weight have been added and the molecule initiators that when exposed to UV radiation is converted monomers into polymers. Thus organogel created IBM, when exposed to UV light becomes hard as plastic.

Demonstration elasticity organogel

After several tens of tests for measuring the hardness of the gel and determine the correct ratio of components, experts have created a modified gel that can be melted at temperatures above 80 degrees Celsius, and which recovers its properties when cooled to 20 degrees. The output scientists have gel (first kind) which can be melted and cooled without losing its unique qualities. Once the gel is formed from such a facility is the desired shape, the resulting object to the effects of UV radiation, which leads to the final hardening of the gel.

Such material may be used for filling cracks. Organogel - sufficient liquid material to penetrate without any problem in a small space, but it does not flow out of them. Exposure to UV radiation allows the material to harden, resulting in a full closing of cracks. In the future, such substances can be used for a 3D printer. However, many modern 3D printers are not perfect, because the layering material leads to a lack of structure and form. A new gel may be used to create almost ideal objects by changing the temperature and the level of UV radiation. According to experts, control the temperature of the gel gets rid of problems with the structure and appearance of the printed patterns.

A - a conventional gel, B - gel created by IBM. On the left - the state of the gels under normal conditions, to the right - the same samples after heating

Continuity

The above gels were created using materials from the project two years ago IBM scientists Jim Hedrick and Jeannette Garcia. Then the scientists have developed a method for the synthesis of industrial polymers. Using the processes discussed in this material allowed to create organogels with the described properties.

Source: geektimes.ru/company/ibm/blog/268986/

10 facts about the "Survivor" and a few reasons why Leo exact receive him "Oscar"

New Horizons passed the most detailed pictures of Pluto for all time