980

3D-printer for the first time published in the product space

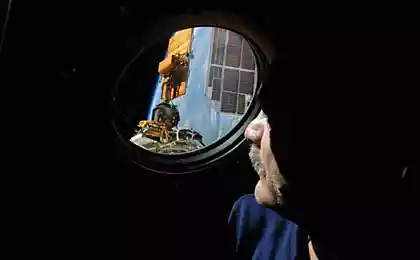

22 September the ISS was taken 3D-printer Zero G, developed by Made In Space, in collaboration with NASA specifically for use in zero gravity . After a series of calibration tests (print took just two gauge parts), astronaut Barry Wilmore (Barry Wilmore) successfully printed front panel of the printer: Aaron Kemmer, CEO of the company, create a printer, put it this way: "Everything went as planned, and may even be a little better ».

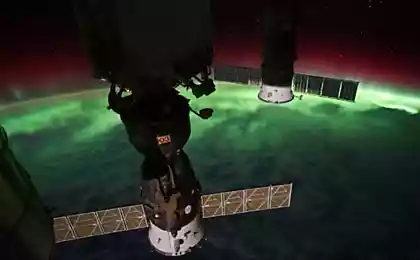

If 3D-press in the world already commonplace, then say the same thing about space while it is impossible. Most "habitable" planet is a place people - is the International Space Station (ISS), and a scenario in which something breaks and cosmonaut, instead of waiting for the desired item from the Earth, looking for CAD-file on the laptop and prints it looks actually quite attractive.

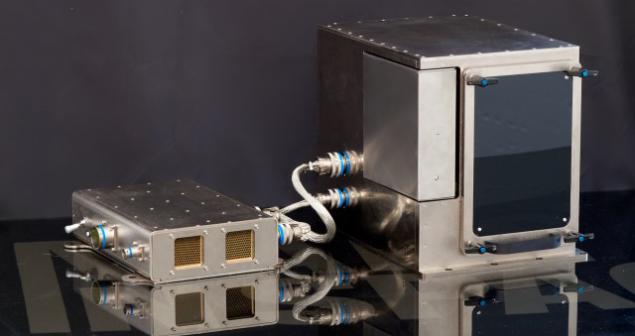

The printer Zero G i>

Printed panel is hardly complicated - it's just a plate measuring 7.6 by 3.8 inches and a thickness of 6 mm and as earlier cases printing microgravity was not, then it will soon return to Earth after a "field test" for the study of its engineers Made in Space. There will be printed a lot of details, including of those that have been obtained as a result of the project Future Engineers , where everyone could send your CAD -file for printing in space.

Kemmer said that Zero-G - is just the beginning of future innovation for 3D-printing in space. Among the planned improvements - a mechanism to reuse plastic parts that are damaged, which should have a positive impact on the autonomy of space flight without the need to have a supply of print.

[ Source ]

Source: geektimes.ru/post/241980/

Renewables in the US caught up with the classic cost of electricity produced

NASA initiates the launch of the asteroids, giving contracts to private companies