810

How are footballs

On February 7 in the US was the final NFL Super Bowl, in which the team met "Indianapolis Colts" and "New Orleans Saints". Today we decided to look at the plant for the production of soccer balls "Wilson Sporting Goods". This company makes the Super Cup match balls since 1966.

8 photos via sportpicture

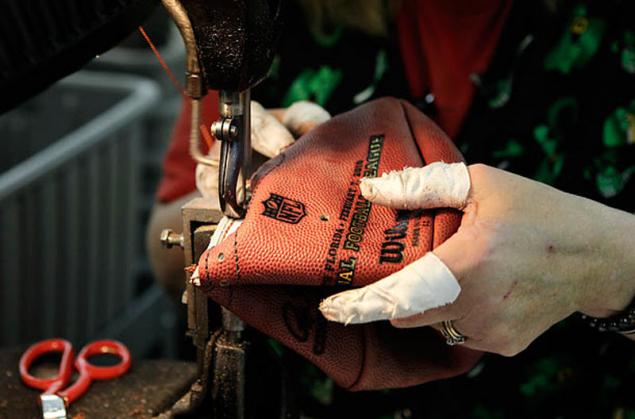

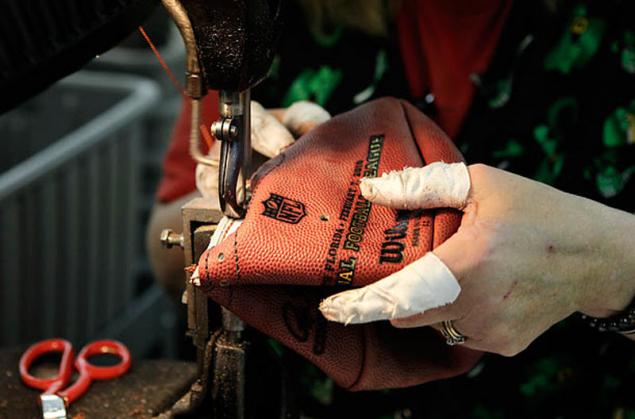

1. Work stitches one of the official balls for the Super Bowl «Super Bowl XLIV» at the plant for the production of football accessories «Wilson Sporting Goods» in Ada, Ohio. On February 7 in Miami team «Indianapolis Colts» met in the finals with the «New Orleans Saints». (Amy Sancetta / AP)

2. Pieces of leather cut into four parts, of which the later will be football. The company «Wilson Sporting Goods» makes balls for the Super Bowl in 1966. (Amy Sancetta / AP)

3. The first four parts of the ball sewn inside. (Amy Sancetta / AP)

4. Next, part sewn in front, where the result will be lacing. (Amy Sancetta / AP)

5. Quality - the main part of the process of production goals. (Amy Sancetta / AP)

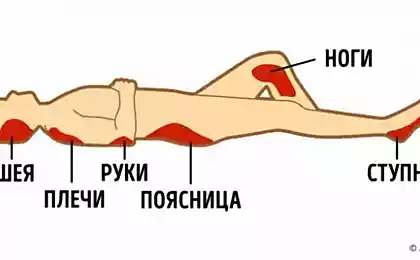

6. Work measures the circumference of the ball. Soccer ball should be 71 cm long, 53 cm in circumference and weigh in the region of 396 - 425 grams. (Amy Sancetta / AP)

7. The last test of strength, the perfect seams and several other factors that should have a perfect football. (Amy Sancetta / AP)

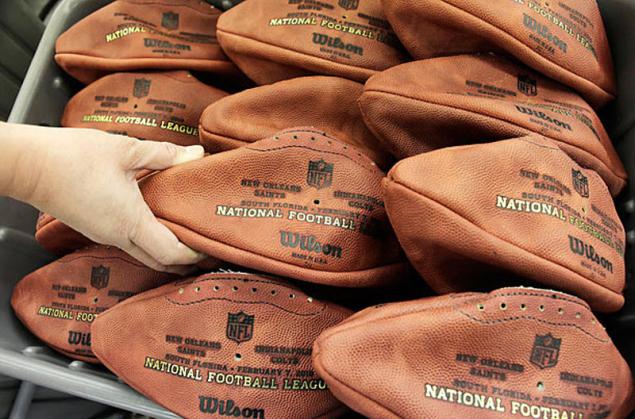

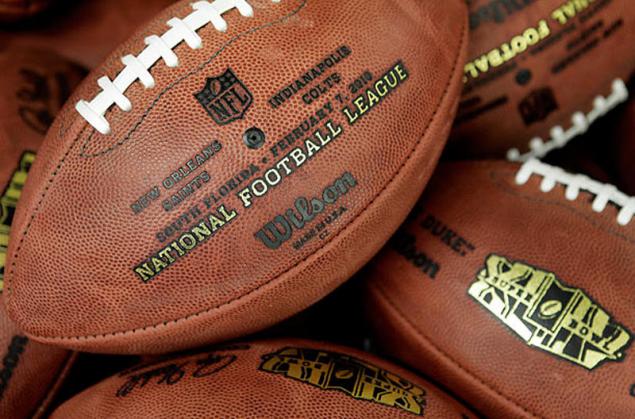

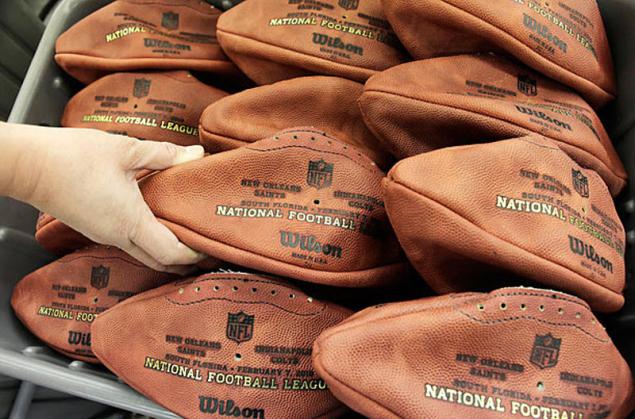

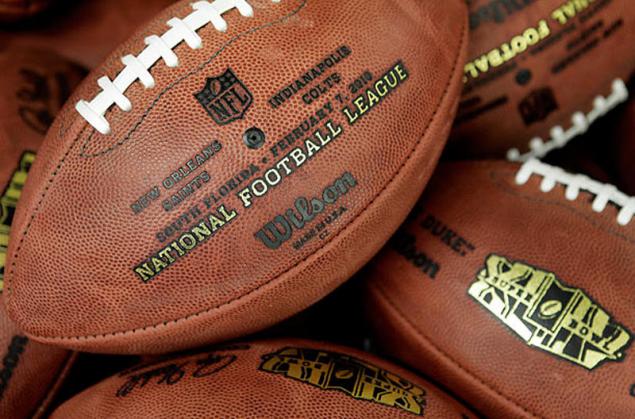

8. Ready footballs - at every game title in the finals of the teams and the final date, coat the NFL and, of course, the initials of the manufacturer. (Amy Sancetta / AP)

Source:

8 photos via sportpicture

1. Work stitches one of the official balls for the Super Bowl «Super Bowl XLIV» at the plant for the production of football accessories «Wilson Sporting Goods» in Ada, Ohio. On February 7 in Miami team «Indianapolis Colts» met in the finals with the «New Orleans Saints». (Amy Sancetta / AP)

2. Pieces of leather cut into four parts, of which the later will be football. The company «Wilson Sporting Goods» makes balls for the Super Bowl in 1966. (Amy Sancetta / AP)

3. The first four parts of the ball sewn inside. (Amy Sancetta / AP)

4. Next, part sewn in front, where the result will be lacing. (Amy Sancetta / AP)

5. Quality - the main part of the process of production goals. (Amy Sancetta / AP)

6. Work measures the circumference of the ball. Soccer ball should be 71 cm long, 53 cm in circumference and weigh in the region of 396 - 425 grams. (Amy Sancetta / AP)

7. The last test of strength, the perfect seams and several other factors that should have a perfect football. (Amy Sancetta / AP)

8. Ready footballs - at every game title in the finals of the teams and the final date, coat the NFL and, of course, the initials of the manufacturer. (Amy Sancetta / AP)

Source: