2401

As the melted gold from the copper ore

In the town of Karabash, Southern Urals, is one of the oldest copper smelting enterprises - Karabashmed.

This company produces copper concentrate, blister copper.

"Kyshtym Copper Electrolyte Plant" located in the Chelyabinsk region Kyshtym. The main activity - production of copper cathodes, copper rod and precious metals from crude copper and copper-containing secondary raw materials. Both companies are under the control of ZAO "Russian Copper Company».

"Karabashmed" - city-forming enterprise of the city of Karabash the Chelyabinsk region. The company is engaged in production of blister copper from copper concentrate, with preliminary enrichment of copper-zinc ore, and from secondary copper raw material.

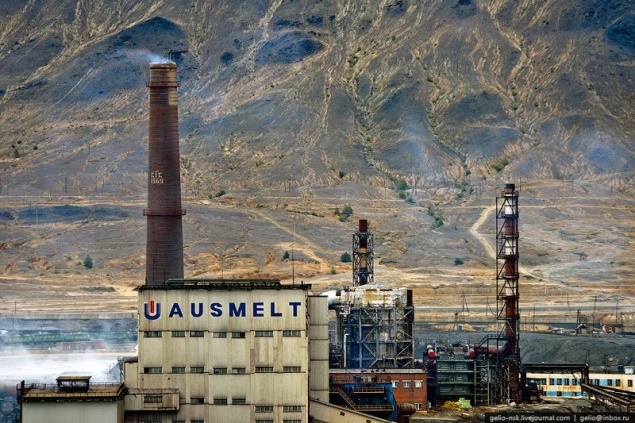

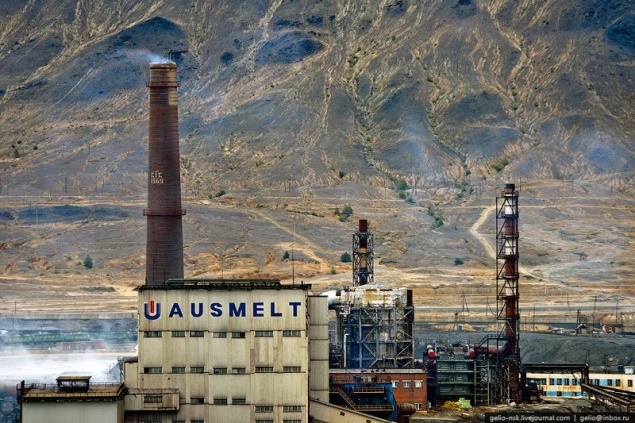

"Karabashmed" Today, the only steel company in Russia, equipped with advanced technology «Ausmelt». In November 2006, a modern small volume copper-smelting furnace with submerged lance Ausmelt replaced by "Karabashmed" six-hundred-year history of shaft furnaces.

There is an old furnace

Loading of copper concentrate

The main building of concentrating mill. Ball mill to a central loading copper-zinc ores.

Commissioning of the new smelting furnace allowed to increase the capacity of the Company to 90 th. Tons of blister copper per year, while the volume of waste gases decreased six times.

General view of the oven «Ausmelt» with tuyeres and service platforms

Fill the converter matte

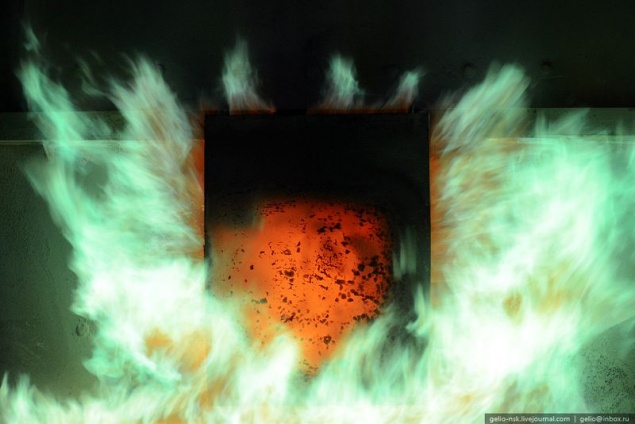

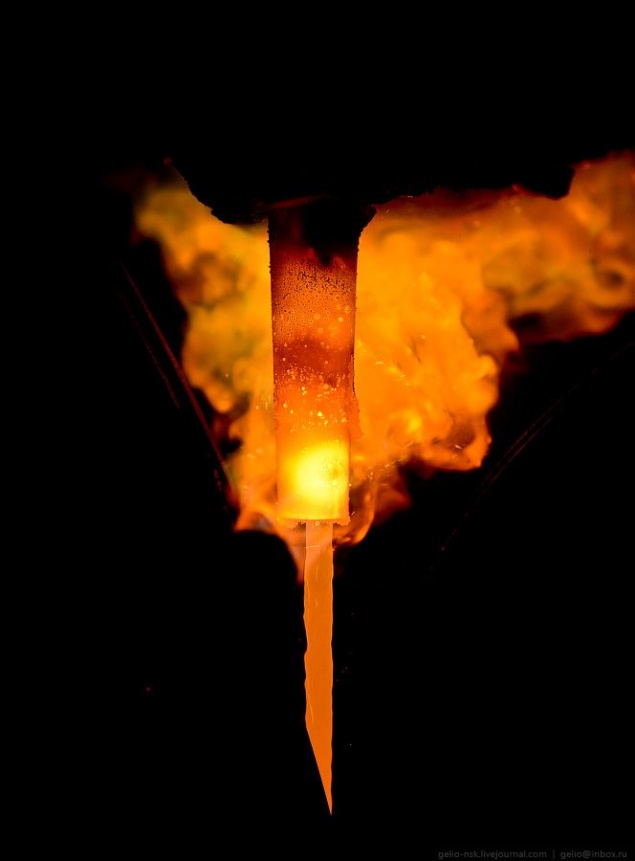

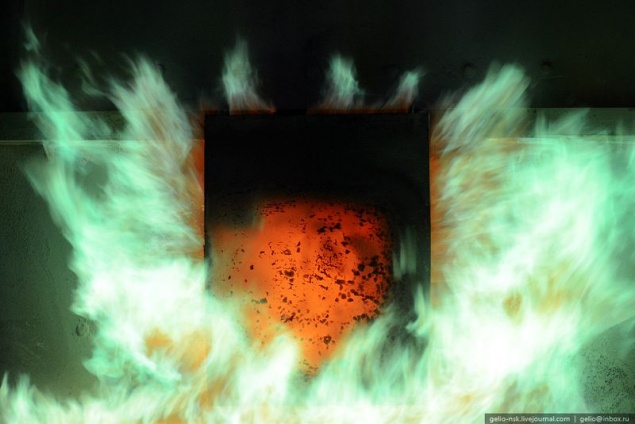

Content smelter run by gravity into the furnace, sump. There's a way out of Gaza. Impurities float up in the form of slag and blister copper is heavier sinks. Smelters periodically, as the accumulation, tapped from the furnace-settler blister copper into molds and slag - in huge buckets.

Draining the converter slag from the converter to the ladle

The temperature of the alloy - 1150 degrees Celsius.

Operator

Issuance of slag from the furnace-mixer

Poured slag shlakovoznuyu bowl of oven-mixer.

Drain slag pit

Very entertaining process!

Due to the fact that during the years of Soviet power equipment enterprise virtually modernized by the end of the XX century the environmental situation in Karabash extremely aggravated. June 25, 1996 the city of Karabash and the surrounding area have been described as an ecological disaster zone.

Since the beginning of the XXI century the factory be gradual modernization of production and transition to more benign to the environment technology. In 2009, the Ministry of Natural Resources and Environment Karabash eliminated from the list of cities with the highest levels of air pollution. Kyshtym Copper Electrolyte Plant

The company conducts fire and electrolytic refining of blister copper, copper scrap and recycling of waste, containing precious metals.

It produces copper and precious metals (as a byproduct of copper refining).

The process of fire refining. Loading the charge into the melting furnace «MAERZ» machine DDS.

The process of fire refining is carried out in the copper smelting shop, capacity 112 ths. Tons of anodes per year.

The shop is equipped with a tilting furnace «MAERZ» capacity of 380 tons, the casting complex M-24 carousel with weight batching and charging machine to autopass.

Sampling from the smelter "MAERZ" to determine the chemical composition and the degree of readiness of the metal.

Remote

Anodorazlivochnaya machine "Outokumpu"

The process of casting metal in a copper mold

Also in the operation has a reflective oven An-1 capacity of 140 tons, the output of 42 thousand. Tonnes of anodes per year

The furnace is equipped with the casting complex M-15 carousel with weight batching.

Loading the charge of the charging device through a loading screen in the reverberatory furnace (AN-1);

Electrolysis bath REM 2

Machine razdvizhki anodes step 102 mm before loading the electrolysis bath

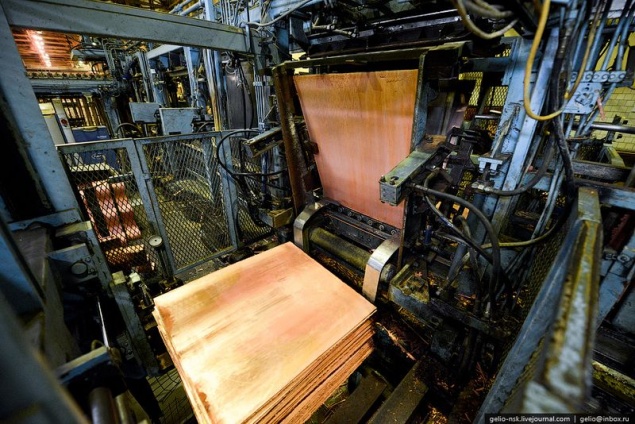

Department of copper electrolysis. The basis of the production process founded the first Russian technology baseless electrolytic refining of copper. Thanks to her, managed to achieve very high purity copper cathode (average copper cathodes - 99, 997%)

Downloaded matrix cathode copper.

Then the washing residues from the anode and the electrolyte slurry and warehousing in the foot.

packaging conveyor cathodes in the second part of the electrolysis of copper (REM-2). After packing steel tape packs cathodes are transferred to shipment.

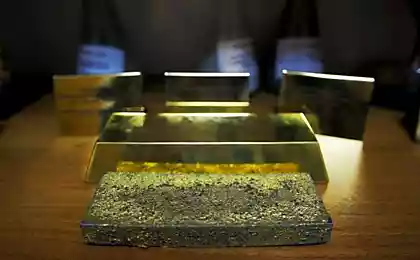

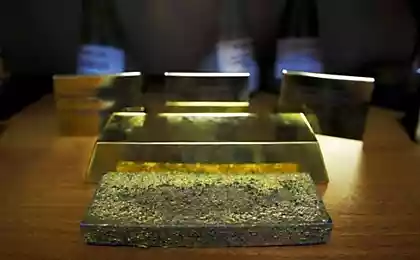

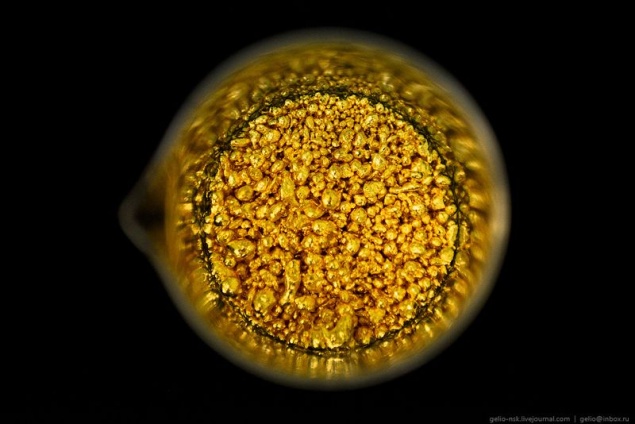

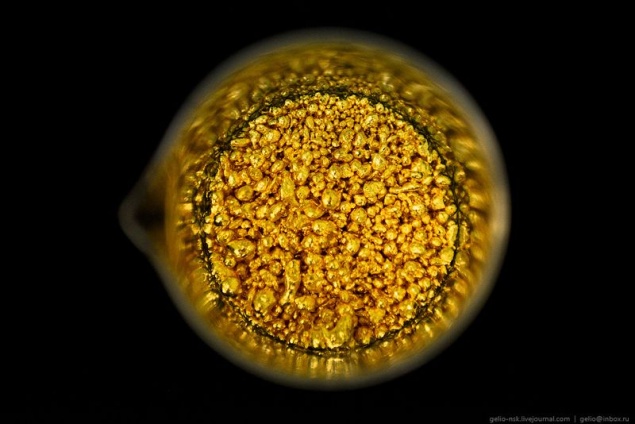

From the blister copper and copper-containing secondary raw materials, the company produces precious metals. For example, in a form originally comes "Gold»

Gold in granules

Silver in granules

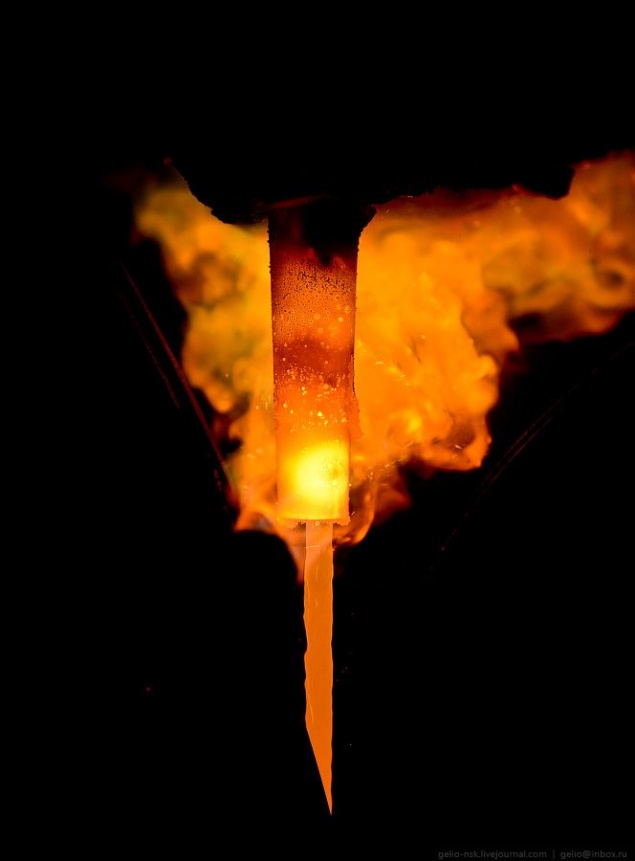

The process of melting the gold in the crucible furnaces for subsequent spill in metal measuring and dimensional gold bullion.

So get gold bullion.

The process of production of copper wire rod

Copper rod produced by continuous casting and rolling

Submission of metal on the casting wheel with filling the bath.

Edit blank before entering the mill.

The packaging process of copper rod (pressing bays and packing tape PET for subsequent transport)

Rack storage control samples of copper rod

For the year Kyshtym Copper Electrolyte Plant produces about 100 tons of copper rod, more than 100 thousand. Tonnes of copper cathodes and more than 100 tons of silver and 3, 7 tons of gold.

Source: kak-eto-sdelano.livejournal.com

This company produces copper concentrate, blister copper.

"Kyshtym Copper Electrolyte Plant" located in the Chelyabinsk region Kyshtym. The main activity - production of copper cathodes, copper rod and precious metals from crude copper and copper-containing secondary raw materials. Both companies are under the control of ZAO "Russian Copper Company».

"Karabashmed" - city-forming enterprise of the city of Karabash the Chelyabinsk region. The company is engaged in production of blister copper from copper concentrate, with preliminary enrichment of copper-zinc ore, and from secondary copper raw material.

"Karabashmed" Today, the only steel company in Russia, equipped with advanced technology «Ausmelt». In November 2006, a modern small volume copper-smelting furnace with submerged lance Ausmelt replaced by "Karabashmed" six-hundred-year history of shaft furnaces.

There is an old furnace

Loading of copper concentrate

The main building of concentrating mill. Ball mill to a central loading copper-zinc ores.

Commissioning of the new smelting furnace allowed to increase the capacity of the Company to 90 th. Tons of blister copper per year, while the volume of waste gases decreased six times.

General view of the oven «Ausmelt» with tuyeres and service platforms

Fill the converter matte

Content smelter run by gravity into the furnace, sump. There's a way out of Gaza. Impurities float up in the form of slag and blister copper is heavier sinks. Smelters periodically, as the accumulation, tapped from the furnace-settler blister copper into molds and slag - in huge buckets.

Draining the converter slag from the converter to the ladle

The temperature of the alloy - 1150 degrees Celsius.

Operator

Issuance of slag from the furnace-mixer

Poured slag shlakovoznuyu bowl of oven-mixer.

Drain slag pit

Very entertaining process!

Due to the fact that during the years of Soviet power equipment enterprise virtually modernized by the end of the XX century the environmental situation in Karabash extremely aggravated. June 25, 1996 the city of Karabash and the surrounding area have been described as an ecological disaster zone.

Since the beginning of the XXI century the factory be gradual modernization of production and transition to more benign to the environment technology. In 2009, the Ministry of Natural Resources and Environment Karabash eliminated from the list of cities with the highest levels of air pollution. Kyshtym Copper Electrolyte Plant

The company conducts fire and electrolytic refining of blister copper, copper scrap and recycling of waste, containing precious metals.

It produces copper and precious metals (as a byproduct of copper refining).

The process of fire refining. Loading the charge into the melting furnace «MAERZ» machine DDS.

The process of fire refining is carried out in the copper smelting shop, capacity 112 ths. Tons of anodes per year.

The shop is equipped with a tilting furnace «MAERZ» capacity of 380 tons, the casting complex M-24 carousel with weight batching and charging machine to autopass.

Sampling from the smelter "MAERZ" to determine the chemical composition and the degree of readiness of the metal.

Remote

Anodorazlivochnaya machine "Outokumpu"

The process of casting metal in a copper mold

Also in the operation has a reflective oven An-1 capacity of 140 tons, the output of 42 thousand. Tonnes of anodes per year

The furnace is equipped with the casting complex M-15 carousel with weight batching.

Loading the charge of the charging device through a loading screen in the reverberatory furnace (AN-1);

Electrolysis bath REM 2

Machine razdvizhki anodes step 102 mm before loading the electrolysis bath

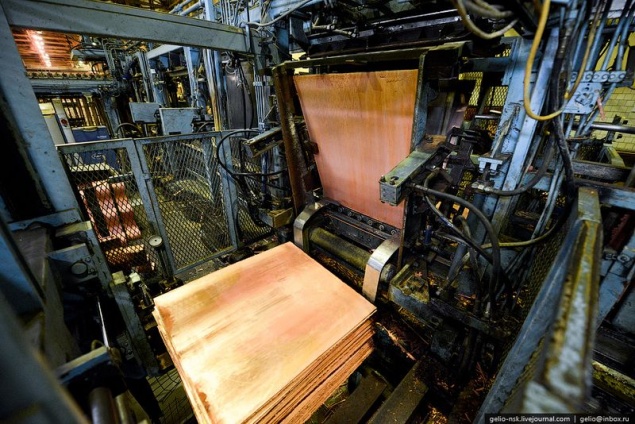

Department of copper electrolysis. The basis of the production process founded the first Russian technology baseless electrolytic refining of copper. Thanks to her, managed to achieve very high purity copper cathode (average copper cathodes - 99, 997%)

Downloaded matrix cathode copper.

Then the washing residues from the anode and the electrolyte slurry and warehousing in the foot.

packaging conveyor cathodes in the second part of the electrolysis of copper (REM-2). After packing steel tape packs cathodes are transferred to shipment.

From the blister copper and copper-containing secondary raw materials, the company produces precious metals. For example, in a form originally comes "Gold»

Gold in granules

Silver in granules

The process of melting the gold in the crucible furnaces for subsequent spill in metal measuring and dimensional gold bullion.

So get gold bullion.

The process of production of copper wire rod

Copper rod produced by continuous casting and rolling

Submission of metal on the casting wheel with filling the bath.

Edit blank before entering the mill.

The packaging process of copper rod (pressing bays and packing tape PET for subsequent transport)

Rack storage control samples of copper rod

For the year Kyshtym Copper Electrolyte Plant produces about 100 tons of copper rod, more than 100 thousand. Tonnes of copper cathodes and more than 100 tons of silver and 3, 7 tons of gold.

Source: kak-eto-sdelano.livejournal.com