1016

Stained glass lamp

Uv. YaPovtsy, I bring to your attention a photo report in the manufacture of decorative lamps home workshop in the Tiffany technique. Will be 39 photos. Do not break.

Production of stained-glass windows of Tiffany technique is not the bonding glass elements with ties, and their soldering tin solder. Each piece of glass grind, wrapped in a copper tape, according to the desired pattern on tracing paper laid out and solder tin soldering on both sides of the other elements of the future stained glass. The finished stained glass patina.

Tools + portable grinder + different chemicals + tin-lead solder

Tools + portable grinder + different chemicals + tin-lead solder

I use the American and German glass. Each sheet is itself a work of art. the average price in Ukraine $ 70 per sheet 0.6-0.8 square meters. in the US this glass is much cheaper. It's one of the reasons for the high cost of stained glass products in our country.

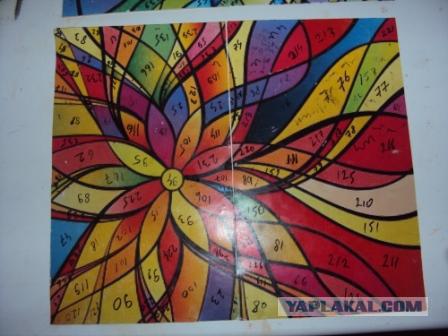

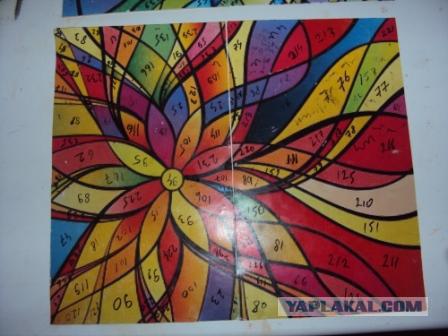

sketch. Unfortunately I draw, I almost do not know. We have to seek the help of other artists or computer adapted to the desired picture stained glass window. To do this, divide the image into segments and then enumerated whatever confused.

Glass cutting I use a glass cutter with a pistol handle

further by shlif.stanka to fit the desired size, remove the jambs. Grinding head is covered with diamond grit.

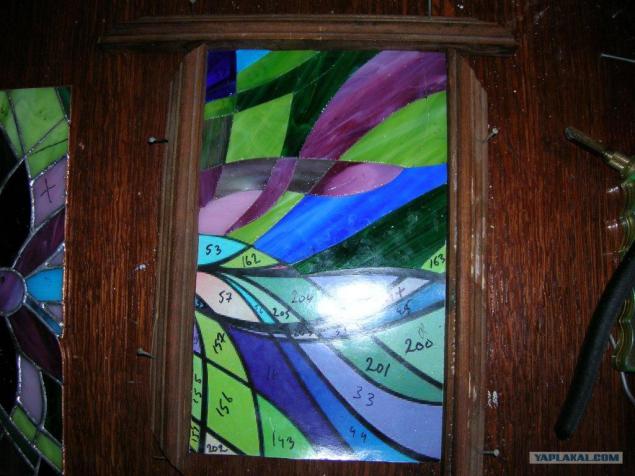

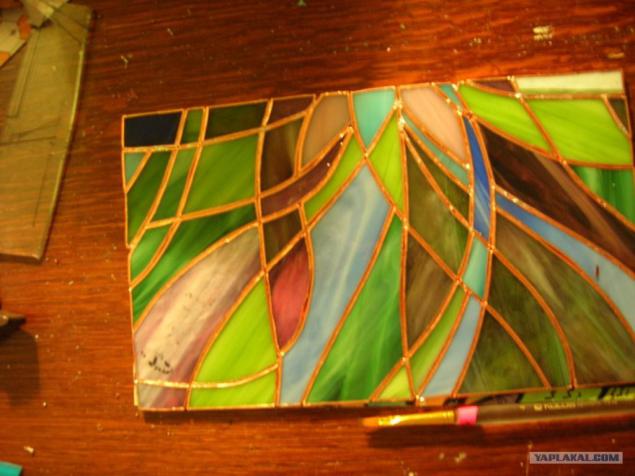

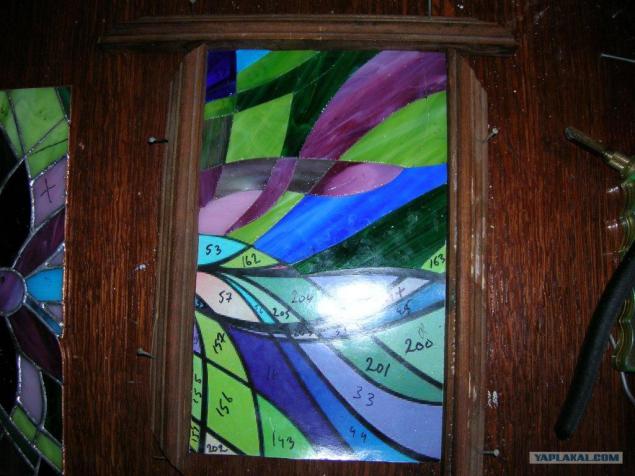

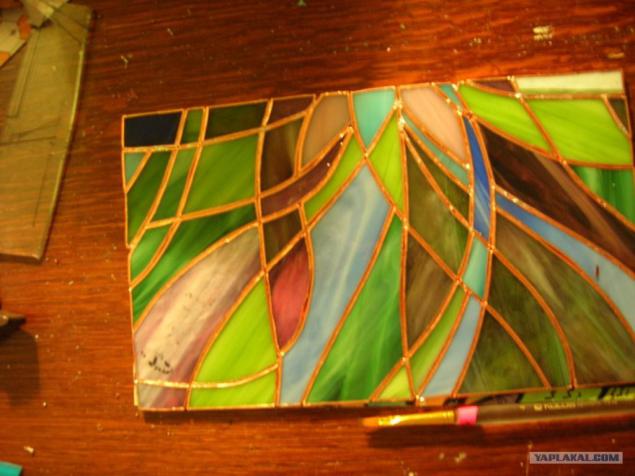

gradually spread like a puzzle

gradually spread like a puzzle

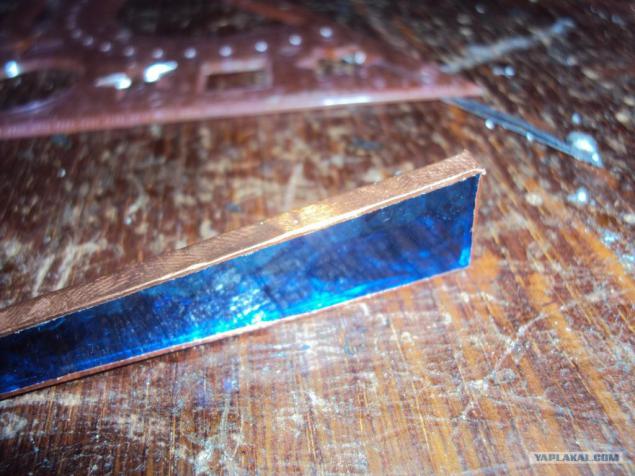

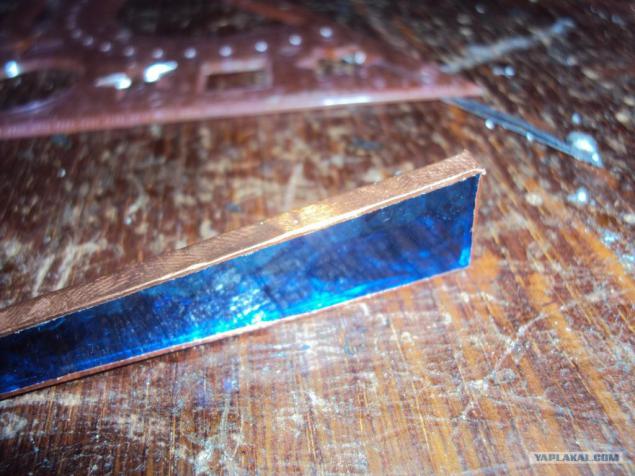

Now we wrap each element copper foliey.

Posted in [mergetime] 1384795423 [/ mergetime]

folia on a special glue, everything is kept very firmly.

folia on a special glue, everything is kept very firmly.

wrapped all the elements

We begin to solder. On the edge, wrap copper foliey to put the soldering acid brush melted tin and now connects elements thus together. Acid and metal evaporation is very harmful to health, so I work with hood and raspiratore.

turn over and solder the opposite direction

Four wall lamp ready

connect wall

stenki.dlya combine strength in the joints between the walls, I fused copper wire.

finish cover. Leaving a small hole for the exit of heated air lamp.

the ceiling is almost ready.

good for fixing the ceiling in a wooden base lamp, bottom pripaevaem just such a design from tekstolita.Nekotorye master used for this purpose brass or no zamarachivatsya and simply inserted into the base ceiling, but I decided that it would be and more beautiful and more reliable.

Next, cover the seams with black patina of metal to put the antioxidant and special oil sheen betrayed seams.

it turns out that's tak.vtoraya side

but to fully appreciate the majestic beauty of stained lamp only when the lamp.

Believe me, the photo is not fully conveys all the magic and beauty of the stained glass when it pass through the light beams.

A little more of my work.

another light, it is more.

second side

third party

fourth

yet stained glass candle holders make great

More

More

More

More

More

More

More

More

More

latest. You can kick a))

Source:

Production of stained-glass windows of Tiffany technique is not the bonding glass elements with ties, and their soldering tin solder. Each piece of glass grind, wrapped in a copper tape, according to the desired pattern on tracing paper laid out and solder tin soldering on both sides of the other elements of the future stained glass. The finished stained glass patina.

Tools + portable grinder + different chemicals + tin-lead solder

Tools + portable grinder + different chemicals + tin-lead solder

I use the American and German glass. Each sheet is itself a work of art. the average price in Ukraine $ 70 per sheet 0.6-0.8 square meters. in the US this glass is much cheaper. It's one of the reasons for the high cost of stained glass products in our country.

sketch. Unfortunately I draw, I almost do not know. We have to seek the help of other artists or computer adapted to the desired picture stained glass window. To do this, divide the image into segments and then enumerated whatever confused.

Glass cutting I use a glass cutter with a pistol handle

further by shlif.stanka to fit the desired size, remove the jambs. Grinding head is covered with diamond grit.

gradually spread like a puzzle

gradually spread like a puzzle

Now we wrap each element copper foliey.

Posted in [mergetime] 1384795423 [/ mergetime]

folia on a special glue, everything is kept very firmly.

folia on a special glue, everything is kept very firmly.

wrapped all the elements

We begin to solder. On the edge, wrap copper foliey to put the soldering acid brush melted tin and now connects elements thus together. Acid and metal evaporation is very harmful to health, so I work with hood and raspiratore.

turn over and solder the opposite direction

Four wall lamp ready

connect wall

stenki.dlya combine strength in the joints between the walls, I fused copper wire.

finish cover. Leaving a small hole for the exit of heated air lamp.

the ceiling is almost ready.

good for fixing the ceiling in a wooden base lamp, bottom pripaevaem just such a design from tekstolita.Nekotorye master used for this purpose brass or no zamarachivatsya and simply inserted into the base ceiling, but I decided that it would be and more beautiful and more reliable.

Next, cover the seams with black patina of metal to put the antioxidant and special oil sheen betrayed seams.

it turns out that's tak.vtoraya side

but to fully appreciate the majestic beauty of stained lamp only when the lamp.

Believe me, the photo is not fully conveys all the magic and beauty of the stained glass when it pass through the light beams.

A little more of my work.

another light, it is more.

second side

third party

fourth

yet stained glass candle holders make great

More

More

More

More

More

More

More

More

More

latest. You can kick a))

Source: