947

Gold production at home

Each of us in the soul a little Plyushkin and certainly many had accumulated a lot of unnecessary old electronics, which must be thrown out, and the hand is not raised. The engineer and chemist Joseph Murchinson found a way out of this situation. He has published a step by step instructions on how to smelt the gold from the old and useless electronic devices. Each electronic card includes a few milligrams of platinum, gold, silver and copper, which may optionally be extracted from e-waste.

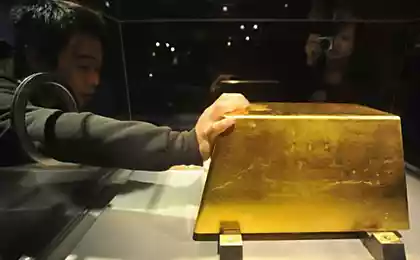

The most profitable gold mine. Joseph Murchinson said that the older electronics - the more there might be gold. First you need to collect all the gold-bearing parts together. In just a few months everyone can gather up a lot of the details. The photographs show that Joseph was able to collect three months.

Details need to sort and using a magnet to remove the gold-plated steel, which requires special process technology.

Cleaned mud auriferous board omitted for one week in a solution of hydrochloric acid (two parts) and hydrogen peroxide (one piece). Daily pot of acid is necessary to stir slightly.

A week later the solution darkens and becomes visible floating exfoliated flakes of gold. They must pass through a coffee filter and wash with methanol.

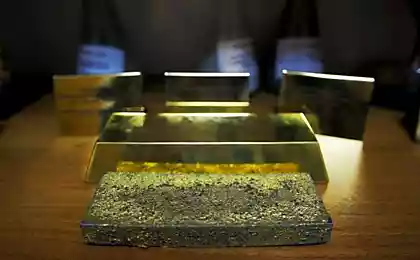

Next you need to fuse the scales in one bar. The melting point of gold is 1063 ° C, so that the conventional burner with the task can not cope. But if the processed gold sodium tetraborate (borax), the melting temperature decreases.

Next, the mixture is melted borax and gold.

Having bullion, you need to weigh it for profit estimates. Here's a bar weighs slightly more than an ounce of (31, 1 g), and is from 600 to 1600 dollars. Not a bad increase in their scholarship for three months of work.

Source: www.instructables.com

The most profitable gold mine. Joseph Murchinson said that the older electronics - the more there might be gold. First you need to collect all the gold-bearing parts together. In just a few months everyone can gather up a lot of the details. The photographs show that Joseph was able to collect three months.

Details need to sort and using a magnet to remove the gold-plated steel, which requires special process technology.

Cleaned mud auriferous board omitted for one week in a solution of hydrochloric acid (two parts) and hydrogen peroxide (one piece). Daily pot of acid is necessary to stir slightly.

A week later the solution darkens and becomes visible floating exfoliated flakes of gold. They must pass through a coffee filter and wash with methanol.

Next you need to fuse the scales in one bar. The melting point of gold is 1063 ° C, so that the conventional burner with the task can not cope. But if the processed gold sodium tetraborate (borax), the melting temperature decreases.

Next, the mixture is melted borax and gold.

Having bullion, you need to weigh it for profit estimates. Here's a bar weighs slightly more than an ounce of (31, 1 g), and is from 600 to 1600 dollars. Not a bad increase in their scholarship for three months of work.

Source: www.instructables.com