477

Silver nanofilm for flexible solar panels and "electronic skin"

New development — ultra-thin transparent film is perfectly conducts electric current. She can find a use in electronics, as researchers of nanomaterials at the University of Illinois in Chicago (USA) and Korea University (South Korea) was found cheap and simple way of producing such a film. As the conductive material using silver nanowires. It can be used in the screens of digital electronics, including wearable.

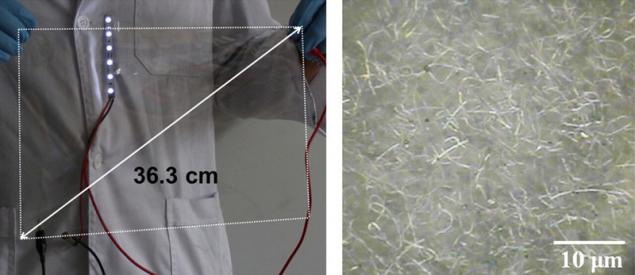

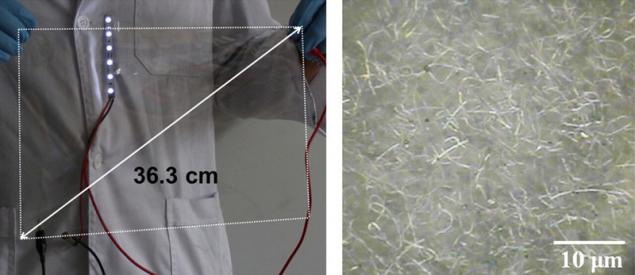

On the left — a fragment of the flexible film with silver nanowires. Right — particles of silver nanowires that are visible under a microscope.

The film is flexible and stretchable, so potentially the use of it can be found in the touch screens, wearable electronics, flexible solar panels and "electronic skin". The results of the study were published in Advanced Functional Materials.

In the new film used is made of fused silver nanowires. It is produced by spraying particles of the nanowires at supersonic speed through a tiny nozzle. In the result, the electric conductivity of the film approximates the electrical conductivity of silverware, said the study's lead author Emeritus Professor of mechanical engineering at the University of Illinois at Chicago Alexander Yarin (Yarin Alexander).

He also explained that the silver nanowires — thin particle lengths. The length of the nanowires is about 20 microns. If you put together four such wires, their total length would be approximately equal to the thickness of a human hair. Can we assume the wires are long? It is possible because the diameter a thousand times smaller than the length, which is much smaller than the wavelength of visible light. This property allows to minimize the scattering of light.

The researchers placed particles of nanowires in water and sprayed them with the help of the Laval nozzle, which is their geometric characteristics similar to a jet engine, but its diameter is only a few millimeters.

The liquid in the atomization process evaporates, the Professor explains Yarin. When nanowires, applied at supersonic speed, hit the surface, they are fused with each other together as their kinetic energy is converted into heat.

The ideal speed for this process, according to Professor yasmin are 400 meters per second. If the energy is too large (for example, at a speed of 600 meters per second), the wires can be damaged. If the speed is too low (for example, 200 meters per second), it is simply not enough to melt wires.

The researchers applied nano-wires and plastic and three-dimensional objects. It turned out that the shape of the surface, which is applied to the nanowires, it doesn't matter.

Clear plastic film can bend and stretch seven times its original length, and it will continue to work complements the above research associate Professor of mechanical engineering, Korea University Sam young (Sam Yoon).

Earlier this year, Alexander Yarin and Sam young with their colleagues have created a transparent electroconductive film by applying the copper electroplating on the "Mat" of nanofibers. In comparison with a film manufactured using copper, a new development by researchers, involving the application of silver nanowires, characterized by higher scalability and provides the ability to produce it in large volumes. published

Source: hi-news.ru/technology/serebryanaya-nanoplenka-dlya-gibkix-solnechnyx-batarej-i-elektronnoj-kozhi.html

On the left — a fragment of the flexible film with silver nanowires. Right — particles of silver nanowires that are visible under a microscope.

The film is flexible and stretchable, so potentially the use of it can be found in the touch screens, wearable electronics, flexible solar panels and "electronic skin". The results of the study were published in Advanced Functional Materials.

In the new film used is made of fused silver nanowires. It is produced by spraying particles of the nanowires at supersonic speed through a tiny nozzle. In the result, the electric conductivity of the film approximates the electrical conductivity of silverware, said the study's lead author Emeritus Professor of mechanical engineering at the University of Illinois at Chicago Alexander Yarin (Yarin Alexander).

He also explained that the silver nanowires — thin particle lengths. The length of the nanowires is about 20 microns. If you put together four such wires, their total length would be approximately equal to the thickness of a human hair. Can we assume the wires are long? It is possible because the diameter a thousand times smaller than the length, which is much smaller than the wavelength of visible light. This property allows to minimize the scattering of light.

The researchers placed particles of nanowires in water and sprayed them with the help of the Laval nozzle, which is their geometric characteristics similar to a jet engine, but its diameter is only a few millimeters.

The liquid in the atomization process evaporates, the Professor explains Yarin. When nanowires, applied at supersonic speed, hit the surface, they are fused with each other together as their kinetic energy is converted into heat.

The ideal speed for this process, according to Professor yasmin are 400 meters per second. If the energy is too large (for example, at a speed of 600 meters per second), the wires can be damaged. If the speed is too low (for example, 200 meters per second), it is simply not enough to melt wires.

The researchers applied nano-wires and plastic and three-dimensional objects. It turned out that the shape of the surface, which is applied to the nanowires, it doesn't matter.

Clear plastic film can bend and stretch seven times its original length, and it will continue to work complements the above research associate Professor of mechanical engineering, Korea University Sam young (Sam Yoon).

Earlier this year, Alexander Yarin and Sam young with their colleagues have created a transparent electroconductive film by applying the copper electroplating on the "Mat" of nanofibers. In comparison with a film manufactured using copper, a new development by researchers, involving the application of silver nanowires, characterized by higher scalability and provides the ability to produce it in large volumes. published

Source: hi-news.ru/technology/serebryanaya-nanoplenka-dlya-gibkix-solnechnyx-batarej-i-elektronnoj-kozhi.html