437

Nanocellulose in medicine and ekoprominvest

Imagine if it would be possible to take one of the most abundant natural materials on earth and use it to alleviate the dire objects to replace synthetic materials or to use it for a prosthesis in a fast-paced science — dentistry?

All this can be possible with the use of cellulose nanocrystals, molecular species of any living plants. They can be mixed with plastic and other synthetic materialit as an industrial filler. They are as much strong as steel, hard as glass, light and environmentally friendly.

"Plastics currently are reinforced by fillers consisting of steel, carbon fibre, Kevlar or glass. There is a constant demand in the production of durable materials that are light weight and are durable enough to replace these fillings," said Douglas M. Fox, associate Professor of chemistry the American University ( American University).

"Cellulose nanocrystals are environmentally friendly filler. If the time will come when they will be widely yspolzuetsya industry, it will significantly reduce the weight of materials that will reduce energy consumption."

Fox has filed a patent for his invention of the cellulose nanocrystals, which includes a simple and scalable technology to improve their performance. The results of the method are published, and you can find them in the journal ACS Applied Materials and Interfaces. The technology of the Fox can be applied in the production of biomaterials for use in Mashinostroenie, construction and production of wind turbines.

The power of pulp

Pulp gives the stems, leaves and other organic materials in the natural world their strength. This property has already been used in many commercial materials. At the nanoscale, the cellulose fibers can be broken down into small particles — particles less than ten millionths of a meter. The researchers prepared crystals of different sizes and strength from cellulose extracted from natural sources, such as derevesina, tunicata (chordates sea cucumbers) and some types of bacteria.

For potential applications in industry obstacle javlaetsa their number.As nanocellulose scatters inside the material, the scientists must find the "sweet spot": the required number of nanoparticles in the matrix, which gives the most durable and the easiest properties. Fox has overcome the four main barrier by changing the surface chemistry of nanocrystals through a simple process of ion exchange. Ion exchange reduces water absorption (cellulose composites lose their strength when absorbing water); increasing the temperature at which the nanocrystals razlagalsa (to be mixed with plastics); reduction pelletizing; and improve re-dispersion after drying of the crystals.

Cell growth

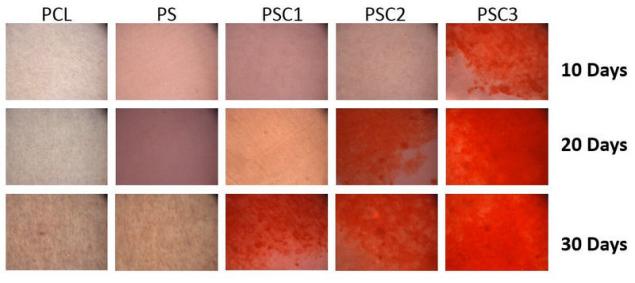

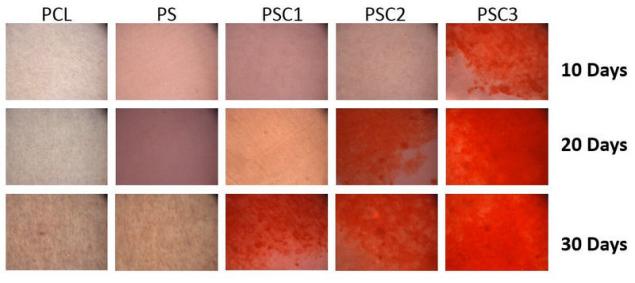

Cellulose nanocrystals as a biomaterial is another commercial term. In dental - restorative medicine is the restoration of the required volume of bone tissue for fixation of the patient's teeth or dental implants. Researchers from the National Institute of standards and technology, on the basis of an agreement with the National Institute of dental and craniofacial research, National institutes of health, looking for a better clinical approach that would help to grow the patient's bone. When the researchers experimented with modified nanocrystals Fox, they were able to apply the nanocrystals in the frames for dental regenerative medicine.

"When we cultured the cells of cellulose nanocrystals using frames, the preliminary results showed great potential of these materials mechanical properties and biological response. This suggests that the cages with the cellulose nanocrystals are a promising approach for bone tissue regeneration," said Martin Chan, head of the biomaterials group NIST project in the field of oral health.

Another area of cooperation is Fox Georgia Institute of Technology and Owens Corning company, specializing in insulation of fiberglass and composite materials. It explores promising materials to replace the fiberglass used in aircraft, automobiles and wind turbines. It also cooperates with the Vireo Advisors and NIST to define the properties and security of cellulose nanocrystals and nanofibres. published

Source: phys.org/news/2016-11-nanocellulose-medicine-green.html

All this can be possible with the use of cellulose nanocrystals, molecular species of any living plants. They can be mixed with plastic and other synthetic materialit as an industrial filler. They are as much strong as steel, hard as glass, light and environmentally friendly.

"Plastics currently are reinforced by fillers consisting of steel, carbon fibre, Kevlar or glass. There is a constant demand in the production of durable materials that are light weight and are durable enough to replace these fillings," said Douglas M. Fox, associate Professor of chemistry the American University ( American University).

"Cellulose nanocrystals are environmentally friendly filler. If the time will come when they will be widely yspolzuetsya industry, it will significantly reduce the weight of materials that will reduce energy consumption."

Fox has filed a patent for his invention of the cellulose nanocrystals, which includes a simple and scalable technology to improve their performance. The results of the method are published, and you can find them in the journal ACS Applied Materials and Interfaces. The technology of the Fox can be applied in the production of biomaterials for use in Mashinostroenie, construction and production of wind turbines.

The power of pulp

Pulp gives the stems, leaves and other organic materials in the natural world their strength. This property has already been used in many commercial materials. At the nanoscale, the cellulose fibers can be broken down into small particles — particles less than ten millionths of a meter. The researchers prepared crystals of different sizes and strength from cellulose extracted from natural sources, such as derevesina, tunicata (chordates sea cucumbers) and some types of bacteria.

For potential applications in industry obstacle javlaetsa their number.As nanocellulose scatters inside the material, the scientists must find the "sweet spot": the required number of nanoparticles in the matrix, which gives the most durable and the easiest properties. Fox has overcome the four main barrier by changing the surface chemistry of nanocrystals through a simple process of ion exchange. Ion exchange reduces water absorption (cellulose composites lose their strength when absorbing water); increasing the temperature at which the nanocrystals razlagalsa (to be mixed with plastics); reduction pelletizing; and improve re-dispersion after drying of the crystals.

Cell growth

Cellulose nanocrystals as a biomaterial is another commercial term. In dental - restorative medicine is the restoration of the required volume of bone tissue for fixation of the patient's teeth or dental implants. Researchers from the National Institute of standards and technology, on the basis of an agreement with the National Institute of dental and craniofacial research, National institutes of health, looking for a better clinical approach that would help to grow the patient's bone. When the researchers experimented with modified nanocrystals Fox, they were able to apply the nanocrystals in the frames for dental regenerative medicine.

"When we cultured the cells of cellulose nanocrystals using frames, the preliminary results showed great potential of these materials mechanical properties and biological response. This suggests that the cages with the cellulose nanocrystals are a promising approach for bone tissue regeneration," said Martin Chan, head of the biomaterials group NIST project in the field of oral health.

Another area of cooperation is Fox Georgia Institute of Technology and Owens Corning company, specializing in insulation of fiberglass and composite materials. It explores promising materials to replace the fiberglass used in aircraft, automobiles and wind turbines. It also cooperates with the Vireo Advisors and NIST to define the properties and security of cellulose nanocrystals and nanofibres. published

Source: phys.org/news/2016-11-nanocellulose-medicine-green.html