1382

Master class on production of the gold ring

Young couple Julia and Andrew have made them wedding rings for the wedding.

Let's look at this process.

It all started with the smelting of gold. Pure gold is very soft to give it the rigidity it is alloyed with other metals - silver, copper, zinc, etc.

After melting the gold will be 585

The photo is not visible, but in the hands of Andrew piece hornbeam)

Pare was very difficult to believe that such a small piece of gold in the evening they will ring)

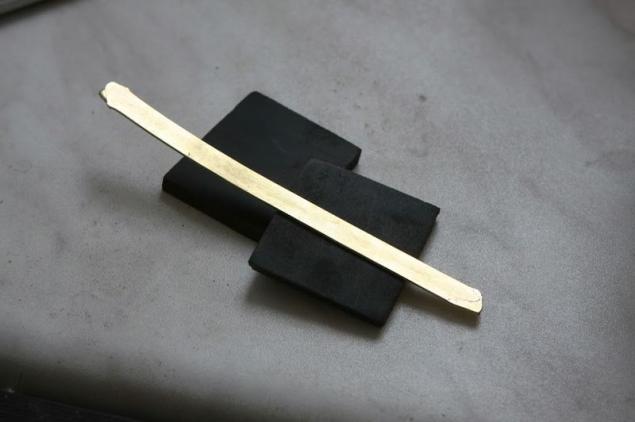

Rolled gold mill

A piece of gold on the sly becomes the desired shape and have prepared the first piece of hornbeam)

Grab a sawed off by a large piece.

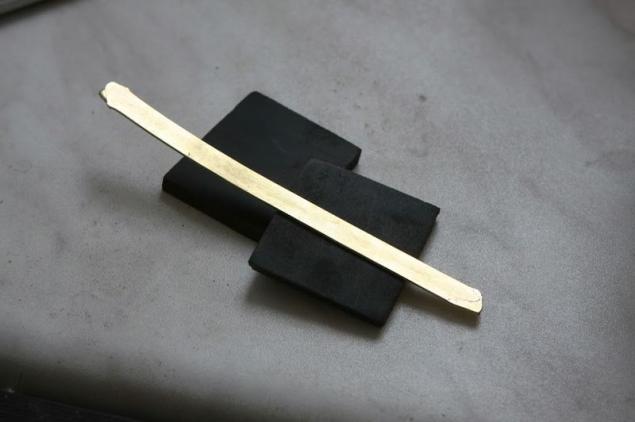

Here's the second piece and a gold bar is almost ready)

But with such a strip can already work on

So, jointly Burke strip)

Strips of gold to heat and leave to cool, so that they become soft. This process is called annealing.

We turned the strip into a ring

And soldered joints

Two welded rings, each in his own piece of hornbeam

Scrollsaw hole under the ring

Customize the hole under the ring on bormashinke

Bravo! All tailored and can proceed to the next step

Defining the line deformation on the gold part

Clench and gold on wood) to this point, and we needed a joke that the metal is not fractured by internal stresses

Next is a matter of technique, opilivaem all unnecessary and polish

First, the inside of the then foreign

And here is the result!

So one day you can make a wedding ring.

Source: master-klass.livejournal.com

Let's look at this process.

It all started with the smelting of gold. Pure gold is very soft to give it the rigidity it is alloyed with other metals - silver, copper, zinc, etc.

After melting the gold will be 585

The photo is not visible, but in the hands of Andrew piece hornbeam)

Pare was very difficult to believe that such a small piece of gold in the evening they will ring)

Rolled gold mill

A piece of gold on the sly becomes the desired shape and have prepared the first piece of hornbeam)

Grab a sawed off by a large piece.

Here's the second piece and a gold bar is almost ready)

But with such a strip can already work on

So, jointly Burke strip)

Strips of gold to heat and leave to cool, so that they become soft. This process is called annealing.

We turned the strip into a ring

And soldered joints

Two welded rings, each in his own piece of hornbeam

Scrollsaw hole under the ring

Customize the hole under the ring on bormashinke

Bravo! All tailored and can proceed to the next step

Defining the line deformation on the gold part

Clench and gold on wood) to this point, and we needed a joke that the metal is not fractured by internal stresses

Next is a matter of technique, opilivaem all unnecessary and polish

First, the inside of the then foreign

And here is the result!

So one day you can make a wedding ring.

Source: master-klass.livejournal.com