724

Car subwoofer-bag (19 photos)

Removing once again in the garage, and stumbled on an old suitcase, the idea to make the suitcase car subwoofer. Advantages of such a solution - a ready exterior trim, protective plastic corners, carrying handle (for the case if, for example, it is necessary to bring home a subwoofer to make the trunk), and of course the original appearance.

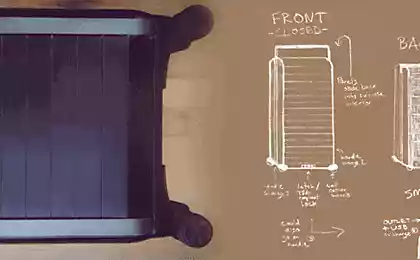

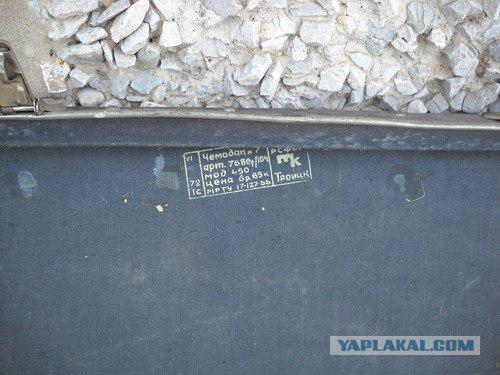

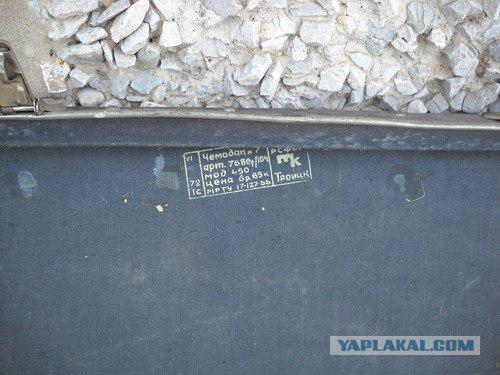

Judging from the press, I came across a suitcase №7 Model 450 production in 1972. Made in the town of Troitsk.

The essence of the assembly consists in implanting a wooden box subwoofer inside the suitcase. According to rough estimates the internal volume of the housing should be about 15-20 liters. This volume is more than enough for most of the 8-inch subwoofer speakers and some 10-inch. I was selected 8-inch speaker Polk Audio models firms DB840 (a favorite of the review 8 inch subwoofers magazine "Car Audio" May 2009). The manufacturer recommends the optimal amount for a closed box 9, 9 liters. The magazine "Auto Sound" recommends that the minimum amount - 11, 5 liters, and for the most flat frequency response - 19 liters.

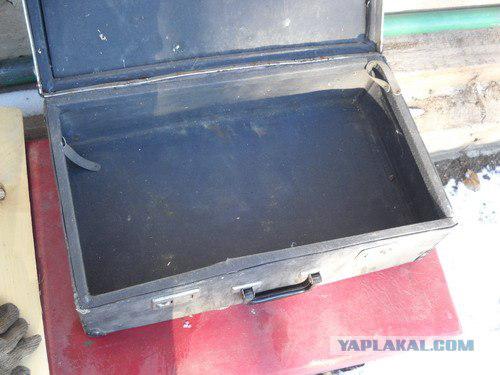

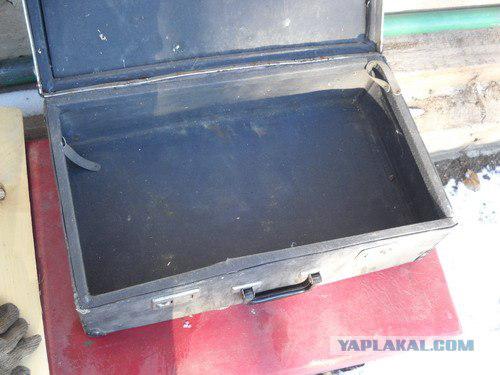

First, where to start - it removes the tissue lining the inside of the frame rails and the main part of the suitcase and make measurements of internal space for making the subwoofer box. The cover is left untouched, it is small in height, a lot of volume to not carve it.

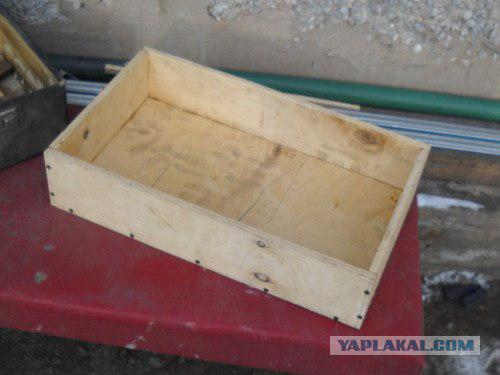

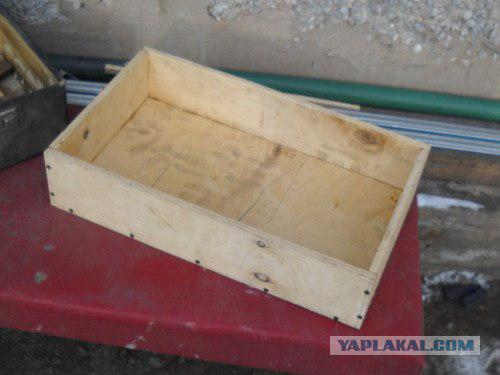

According to the obtained size cut into panels for subwoofer enclosures. You can take for the body as a particle board and plywood. The material thickness of 14-20 mm. I took plywood 14 mm thick, as The remaining half of the sheet from the previous project.

From these panels on the screws and epoxy adhesive collect box subwoofer.

The resulting try on a box in a suitcase, and temporarily fasten the panel, which will be attached Subwoofer.

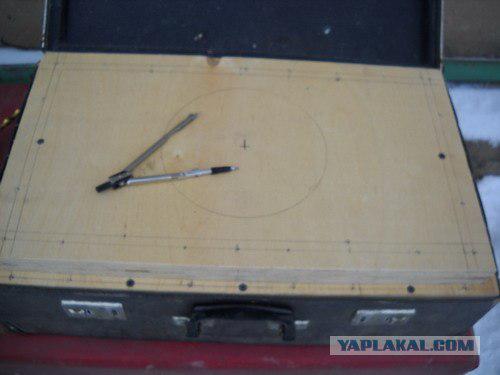

To cover suitcases became like one makes with the subwoofer enclosure, backfilled panel, which will be attached Subwoofer. It took me another 2 panels of plywood.

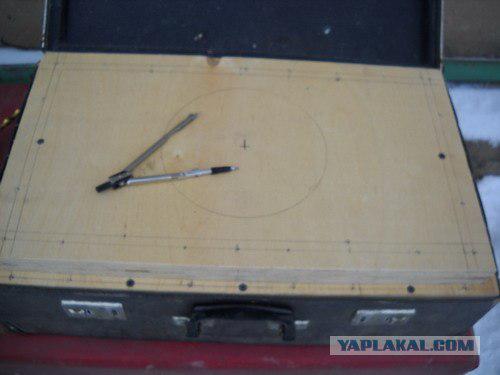

Note the compass circuit next hole Subwoofer.

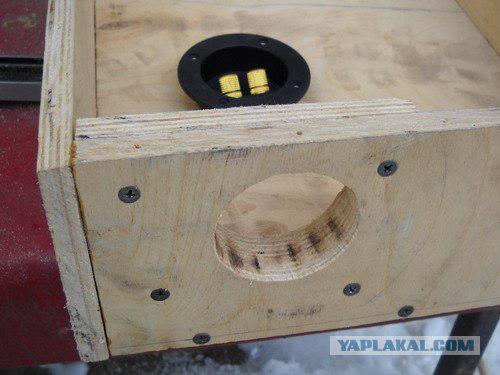

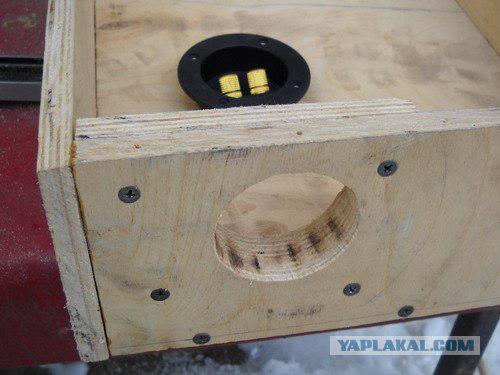

Jigsaw to cut a hole in the front panel. It is unlikely that some industrial subwoofer will be the thickness of the front panel.

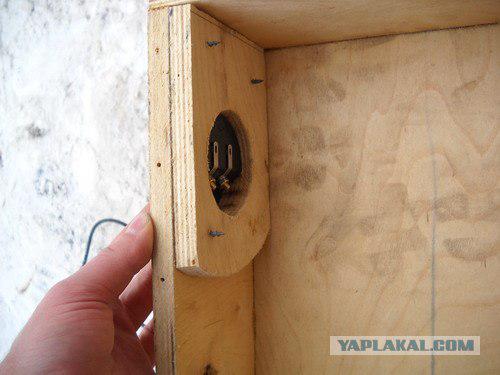

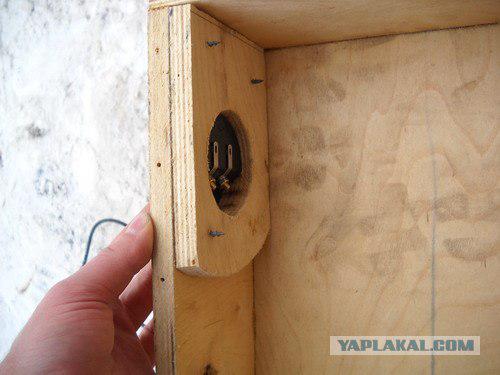

We take out the body of the suitcase, to a one end of the housing to cut a hole under the terminal acoustic quick connect-disconnect the subwoofer to the amplifier.

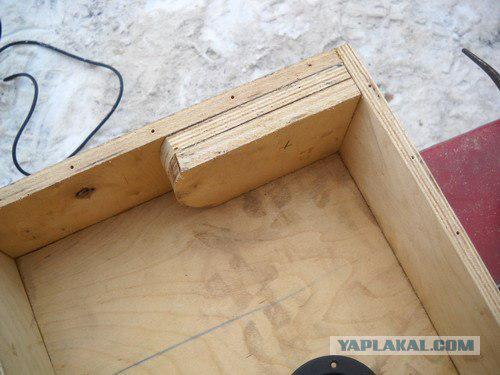

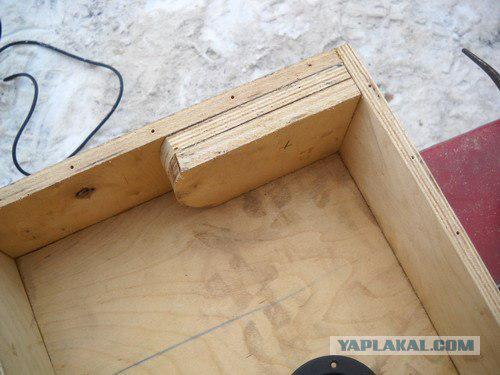

Since the terminal is made of thin plastic, it is sure to be a rattle and emit other sounds. Therefore, we isolate the terminal from the internal volume of the subwoofer enclosure. To do this, we use a pair of plywood scraps left after cutting out the holes for the speaker. One use scrap as a spacer, and the second as a hollow wall, which later will make a small hole for the wiring from the terminal to the Subwoofer.

Here's a sandwich

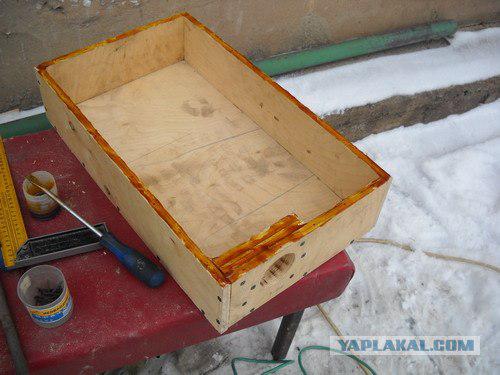

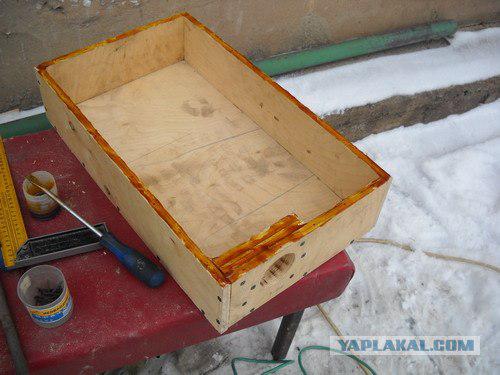

We coat the ends of the box subwoofer epoxy to seal and greater strength.

And fasten the front panel of the subwoofer screws. Screws do not regret. Sandwich the front panel of the 3 layers of plywood and the whole area of the fastening screws.

The internal volume of measured water, was about 15 liters. It receives an average value between the recommended magazine "Auto Sound".

Install assembled plywood subwoofer enclosure in a suitcase, in which a sharp knife cut a hole for the speaker and the terminal.

And the last step - fluster wire to the terminal and the dynamics were washed surface of the suitcase, fasten the terminal and the speaker himself in his place.

Source: www.mariklab.ru

Source:

Judging from the press, I came across a suitcase №7 Model 450 production in 1972. Made in the town of Troitsk.

The essence of the assembly consists in implanting a wooden box subwoofer inside the suitcase. According to rough estimates the internal volume of the housing should be about 15-20 liters. This volume is more than enough for most of the 8-inch subwoofer speakers and some 10-inch. I was selected 8-inch speaker Polk Audio models firms DB840 (a favorite of the review 8 inch subwoofers magazine "Car Audio" May 2009). The manufacturer recommends the optimal amount for a closed box 9, 9 liters. The magazine "Auto Sound" recommends that the minimum amount - 11, 5 liters, and for the most flat frequency response - 19 liters.

First, where to start - it removes the tissue lining the inside of the frame rails and the main part of the suitcase and make measurements of internal space for making the subwoofer box. The cover is left untouched, it is small in height, a lot of volume to not carve it.

According to the obtained size cut into panels for subwoofer enclosures. You can take for the body as a particle board and plywood. The material thickness of 14-20 mm. I took plywood 14 mm thick, as The remaining half of the sheet from the previous project.

From these panels on the screws and epoxy adhesive collect box subwoofer.

The resulting try on a box in a suitcase, and temporarily fasten the panel, which will be attached Subwoofer.

To cover suitcases became like one makes with the subwoofer enclosure, backfilled panel, which will be attached Subwoofer. It took me another 2 panels of plywood.

Note the compass circuit next hole Subwoofer.

Jigsaw to cut a hole in the front panel. It is unlikely that some industrial subwoofer will be the thickness of the front panel.

We take out the body of the suitcase, to a one end of the housing to cut a hole under the terminal acoustic quick connect-disconnect the subwoofer to the amplifier.

Since the terminal is made of thin plastic, it is sure to be a rattle and emit other sounds. Therefore, we isolate the terminal from the internal volume of the subwoofer enclosure. To do this, we use a pair of plywood scraps left after cutting out the holes for the speaker. One use scrap as a spacer, and the second as a hollow wall, which later will make a small hole for the wiring from the terminal to the Subwoofer.

Here's a sandwich

We coat the ends of the box subwoofer epoxy to seal and greater strength.

And fasten the front panel of the subwoofer screws. Screws do not regret. Sandwich the front panel of the 3 layers of plywood and the whole area of the fastening screws.

The internal volume of measured water, was about 15 liters. It receives an average value between the recommended magazine "Auto Sound".

Install assembled plywood subwoofer enclosure in a suitcase, in which a sharp knife cut a hole for the speaker and the terminal.

And the last step - fluster wire to the terminal and the dynamics were washed surface of the suitcase, fasten the terminal and the speaker himself in his place.

Source: www.mariklab.ru

Source: