766

How to make the boots in Belarus (13 photos)

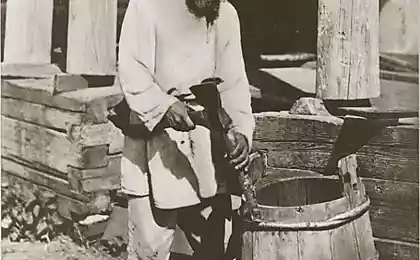

Reuters correspondent made a photo report from the manufacture of boots on Smilovichskaya felting factory,

which is located in the town of Smilovichi 35 kilometers from Minsk. Boots are fooling the third century.

The Belarusian town Smilovichi the XIX century is actively developing small-scale production of boots. After the October Revolution in the 20s of the twentieth century there was formed gang "Red Star", which consisted of craftsmen that made the boots and galoshes at home by hand.

In 1928, the cooperative has grown from a factory. Shoes continued to do it by hand, worked on the production of almost exclusively male. They fingered hair and combed it for carding machines, which are actuated by means of horses. Then the wool was compressed and lying in the boilers, which are fueled by the fire. Boots dried in the sun in the summer or winter on home furnaces.

In 1930, construction began on the first factory building and the boiler house. Now the machine is driven using engine oil. Then it was installed a steam locomobile, Molotov machine boiler machines. Production volumes have increased by several times - in the 20 years the day was created 80-90 pairs of boots, and in 1969 - 650 pairs of Bole.

In 2006, a new factory, Italian equipment, which is done for the sole boots. Today fakbrike, in addition to 15 kinds of boots, produces three types of quilts filled with wool.

Now, according to management, the factory produces 17 thousand pairs per month. This winter she starts supply boots to Austria. Most shoe factory sells in Russia - 57 thousand pairs for 2012, representing 80% of total production.

a source

which is located in the town of Smilovichi 35 kilometers from Minsk. Boots are fooling the third century.

The Belarusian town Smilovichi the XIX century is actively developing small-scale production of boots. After the October Revolution in the 20s of the twentieth century there was formed gang "Red Star", which consisted of craftsmen that made the boots and galoshes at home by hand.

In 1928, the cooperative has grown from a factory. Shoes continued to do it by hand, worked on the production of almost exclusively male. They fingered hair and combed it for carding machines, which are actuated by means of horses. Then the wool was compressed and lying in the boilers, which are fueled by the fire. Boots dried in the sun in the summer or winter on home furnaces.

In 1930, construction began on the first factory building and the boiler house. Now the machine is driven using engine oil. Then it was installed a steam locomobile, Molotov machine boiler machines. Production volumes have increased by several times - in the 20 years the day was created 80-90 pairs of boots, and in 1969 - 650 pairs of Bole.

In 2006, a new factory, Italian equipment, which is done for the sole boots. Today fakbrike, in addition to 15 kinds of boots, produces three types of quilts filled with wool.

Now, according to management, the factory produces 17 thousand pairs per month. This winter she starts supply boots to Austria. Most shoe factory sells in Russia - 57 thousand pairs for 2012, representing 80% of total production.

a source