481

Fluoropolymer technical features and application

Eighty four million six hundred twenty six thousand one hundred ninety three

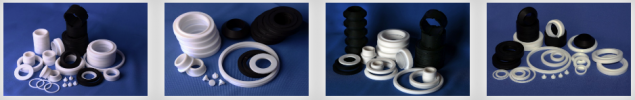

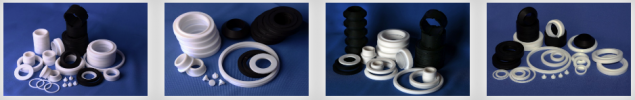

Teflon is a polymer of ethylene porpoising, which is obtained through the polymerization process in a low-boiling gaseous monomers in the auto-clave under increased pressure. Often this material can be produced in several forms, for example as a powder or a variety of compositions, quality of semi-finished products or ready products. However, all of the products is the General name for PTFE, you may buy for a fairly nice price today is not a problem.

This material is truly unique, as it has excellent chemical resistance and boiling in absolute alcohol is not changed. In addition, the material is characterized not only by the inertia of the phenomenal strength, but also good mechanical, electrical properties and a low degree of porosity. The great mechanical strength of the material species are able to persist under a regime of temperature from minus twenty to plus couple dozen degrees Celsius. Teflon has a negligible coefficient of friction that the indicators thermometers can not depend on almost any grams, while it is inert relative to its physiology and hydrophobic.

The natural characteristics of its dielectric constant to a value of two hundred degrees, the chemical to three hundred Celsius. The data inherent in the substance features make made of it products in absolutely indispensable in the following areas:

In order to improve heat conductivity, the level of hardness and resistance to abrasion, and to reduce the coefficient of thermal expansion and deformation under load, this material is added a variety of fillers that can withstand temperature of its recycling. With this purpose, exploited, often, the following inorganic species:

More details can be found on the website https://ftoropolimer.com.ua/ftoroplast.php

Teflon is a polymer of ethylene porpoising, which is obtained through the polymerization process in a low-boiling gaseous monomers in the auto-clave under increased pressure. Often this material can be produced in several forms, for example as a powder or a variety of compositions, quality of semi-finished products or ready products. However, all of the products is the General name for PTFE, you may buy for a fairly nice price today is not a problem.

This material is truly unique, as it has excellent chemical resistance and boiling in absolute alcohol is not changed. In addition, the material is characterized not only by the inertia of the phenomenal strength, but also good mechanical, electrical properties and a low degree of porosity. The great mechanical strength of the material species are able to persist under a regime of temperature from minus twenty to plus couple dozen degrees Celsius. Teflon has a negligible coefficient of friction that the indicators thermometers can not depend on almost any grams, while it is inert relative to its physiology and hydrophobic.

The natural characteristics of its dielectric constant to a value of two hundred degrees, the chemical to three hundred Celsius. The data inherent in the substance features make made of it products in absolutely indispensable in the following areas:

- instrument and engineering;

- light, food and medical type of industry, however, as electrical and chemical;

- the nuclear power industry.

In order to improve heat conductivity, the level of hardness and resistance to abrasion, and to reduce the coefficient of thermal expansion and deformation under load, this material is added a variety of fillers that can withstand temperature of its recycling. With this purpose, exploited, often, the following inorganic species:

- Carbon fiber.

- Bronze.

- The molybdenum disulfide.

- The Nickel powder.

- Quartz.

- Fiberglass chopped.

- Coke powder.

- Asbestos.

- Copper ore.

- The boron nitride.

- Graphite.

- The powder is made of zirconium.

More details can be found on the website https://ftoropolimer.com.ua/ftoroplast.php