644

Birth of Sukhoi Su-34.

Not so long ago, thanks to the efforts of the KLA, I was able to visit the Novosibirsk aircraft plant them. Chkalov (NAE), the branch of OJSC "Company" Sukhoi "which produces the legendary Cy - 34.

March 20, 2014 Su-34 combat aircraft became the first officially accepted into service in post-Soviet Russia.

NATO has called the bomber Fullback («Defender"), our own pilots affectionately called his "duck" and certainly this is the explanation. But when this "duck" advancing on the runway, passing 7-10 feet away from me, I felt a delight from beauty and power of the steel bird!

38 pictures. Source

01. Contours bomber resemble huge ramp that lurked in the depths ...

What it reminds me of this engine (which is the engine of "drying") and recalled similar units were the first aircraft of the young Sky Walker from Star Wars, when he competed in his first aircraft!

02.

I'm not the first time at such facilities, so surprising usual conversation at the checkpoint, equipment and inventory contributed briefing. Then we start to work.

Just think, the Su-34 includes 57 thousand items, which must be collected in the correct order. Some units, such as the engine, are not collected here, and at other factories, where he is being tested, and shipped to the assembly shop, where it is mounted in the body of the aircraft.

03.

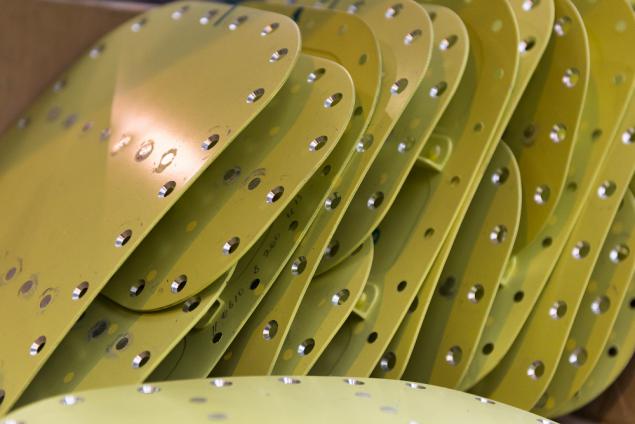

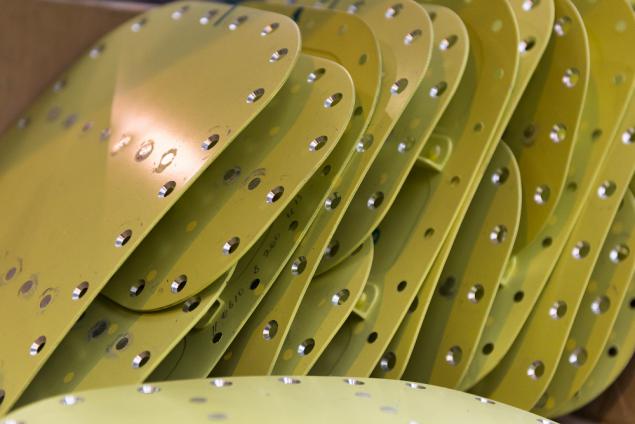

We are one of the many aggregate-assembly plants. The most laborious and tedious process during assembly of the fuselage - drilling. Previously all holes drilled directly on the slipway hand drill. Now automatic pre-drill small holes on the machine, and then to the desired diameter of the drill stocks.

04.

05.

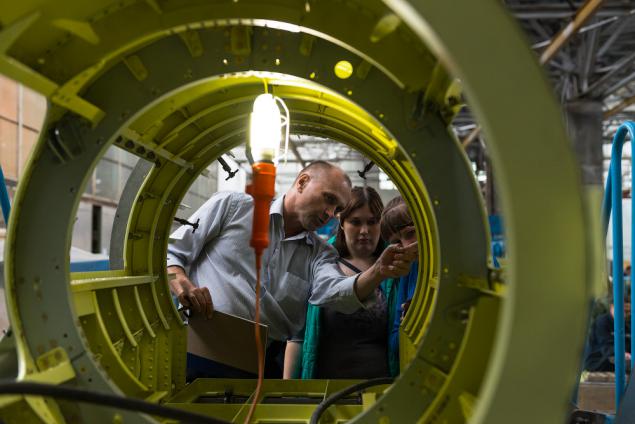

Assembling the air intakes and matchmaking center-stacker - warhead, air intakes, tail section. The work carries a team of 15 people for about two weeks.

In the jargon of our satellite, Eugene Baranov (Deputy Head of the department), the first two steps can be briefly described as follows: "Here people drill, rivet, joint and boltiruyut».

06.

07.

08.

09.

10.

The third stage is the assembly shop inetersno - check machine for leaks. I first heard this word - irrigation. A team that performs this procedure is called dozhdevalschikami. It looks really simple, the car driven into a huge boxing and watered. The machine design is complicated, and not in all the places a person can get. To avoid errors and malfunctions, invented a chip, enclose the special paper, where necessary, and then the entire machine zalyuchivayut and watered. After the completion of irrigation watching if the paper gets wet, then the percentage of the ingress of water and eliminate the channels which is wet.

11.

We arrived a little earlier, the machine is not ready to irrigated trials, but there's as they say, was discharged as a pass.

12.

13.

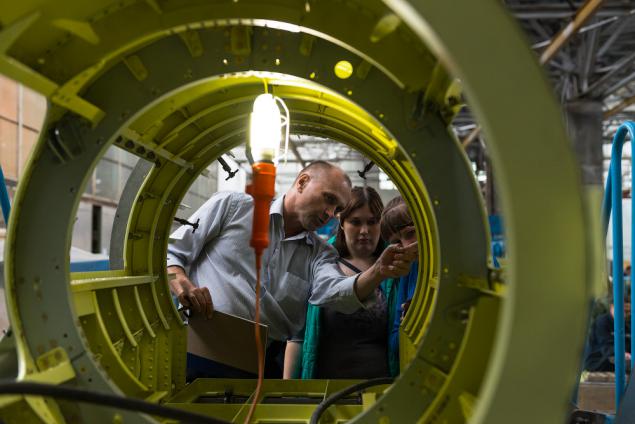

Wishes to look at the assembly plant on top there? With these words, we were approached by one of the staff shop. Along with the military correspondent of the newspaper, I climb on a special platform where we waited for Oksana - crane operator. With this crane is transported by various pieces of heavy body aircraft. Well, we just swept along the entire plant.

14.

Preparing the body for drying the leak test.

15.

The shop at the same time working on multiple machines. By the way, at the end of the shop, behind a fence, production Superjet.

16.

17.

18.

19.

Assembly shop, staffed with wings. Immediately finalized fuel system.

20.

Acceptance Commission.

21.

A fragment of the fuel tank. System paging and swapping the fuel tank is located under on the center and consists of pumps and pipelines. In short, and without the technical details, this system is responsible for the uniform balalans fuel throughout the system, and most interestingly, in all modes of flight! Honestly, I thought that the car just standing conventional tanks, well, maybe some sort of special form, due to constructional nuances, but no!

22.

A sense of humor, even at such a serious production must be present)

23.

Acceptance of work.

24.

Transportation fragment wing.

25.

26.

27.

Instead of lunch we go to look at the testing of ready-made aircraft. Again, verification of documents and a few minutes later we are on the field. At the start of preparing two cars, one had just stepped out of the stocks of the plant, the second is painted - this is her last test flight. She sits in the regiment assigned to it.

28.

Not yet fledgeling today he first tests. Many people mistakenly believe, since Soo -34 became mass-produced, what his experience in different modes? This view is fundamentally disagree factory - because during all the tests necessary to provide that pilots often fly to drill safely, confidently and safely!

29.

While I'm trying to keep warm in the freezing wind. This machine runs the latest preflight preparation. The pilots in the cockpit.

30.

Look professional with a capital letter. The guys know their stuff all 150 percent! By the way, they check the flight performance of the machine flying at extremely low and high altitudes, as much as possible in a supersonic mode. In these modes, in line units do not fly! We test pilot only 4 flight two hours factory pilots and 3 flight More pilots are already a customer.

31.

Before being tested by entrance of all wings and planes.

32.

So transported to the test one more car.

33.

Honored test pilot Valeriy Potashёv. He is now 66 years old, work experience Flight 43, just imagine how much you need to be strong in that 66 years have access to such in flights!

Valery Serpionovich said that in one test flight the machine tested 350 modes. Checks overall performance of the aircraft systems, engines and airborne radar equipment.

34.

35.

36.

Perhaps this is the most memorable, when the 7-10 meters away from me this machine thundered, bringing to the runway. The roar of the engines, and covers a second or two can not hear anything. Then, just before the takeoff, the Su-34 has cut the engines at full power. You would know how it is now loudly told us the officer standing beside ...

37.

New steel bird, having made a short run, sharply off the ground, and a few seconds later disappeared among low drifting clouds towards the sun, and to the place of their habitat.

End)

March 20, 2014 Su-34 combat aircraft became the first officially accepted into service in post-Soviet Russia.

NATO has called the bomber Fullback («Defender"), our own pilots affectionately called his "duck" and certainly this is the explanation. But when this "duck" advancing on the runway, passing 7-10 feet away from me, I felt a delight from beauty and power of the steel bird!

38 pictures. Source

01. Contours bomber resemble huge ramp that lurked in the depths ...

What it reminds me of this engine (which is the engine of "drying") and recalled similar units were the first aircraft of the young Sky Walker from Star Wars, when he competed in his first aircraft!

02.

I'm not the first time at such facilities, so surprising usual conversation at the checkpoint, equipment and inventory contributed briefing. Then we start to work.

Just think, the Su-34 includes 57 thousand items, which must be collected in the correct order. Some units, such as the engine, are not collected here, and at other factories, where he is being tested, and shipped to the assembly shop, where it is mounted in the body of the aircraft.

03.

We are one of the many aggregate-assembly plants. The most laborious and tedious process during assembly of the fuselage - drilling. Previously all holes drilled directly on the slipway hand drill. Now automatic pre-drill small holes on the machine, and then to the desired diameter of the drill stocks.

04.

05.

Assembling the air intakes and matchmaking center-stacker - warhead, air intakes, tail section. The work carries a team of 15 people for about two weeks.

In the jargon of our satellite, Eugene Baranov (Deputy Head of the department), the first two steps can be briefly described as follows: "Here people drill, rivet, joint and boltiruyut».

06.

07.

08.

09.

10.

The third stage is the assembly shop inetersno - check machine for leaks. I first heard this word - irrigation. A team that performs this procedure is called dozhdevalschikami. It looks really simple, the car driven into a huge boxing and watered. The machine design is complicated, and not in all the places a person can get. To avoid errors and malfunctions, invented a chip, enclose the special paper, where necessary, and then the entire machine zalyuchivayut and watered. After the completion of irrigation watching if the paper gets wet, then the percentage of the ingress of water and eliminate the channels which is wet.

11.

We arrived a little earlier, the machine is not ready to irrigated trials, but there's as they say, was discharged as a pass.

12.

13.

Wishes to look at the assembly plant on top there? With these words, we were approached by one of the staff shop. Along with the military correspondent of the newspaper, I climb on a special platform where we waited for Oksana - crane operator. With this crane is transported by various pieces of heavy body aircraft. Well, we just swept along the entire plant.

14.

Preparing the body for drying the leak test.

15.

The shop at the same time working on multiple machines. By the way, at the end of the shop, behind a fence, production Superjet.

16.

17.

18.

19.

Assembly shop, staffed with wings. Immediately finalized fuel system.

20.

Acceptance Commission.

21.

A fragment of the fuel tank. System paging and swapping the fuel tank is located under on the center and consists of pumps and pipelines. In short, and without the technical details, this system is responsible for the uniform balalans fuel throughout the system, and most interestingly, in all modes of flight! Honestly, I thought that the car just standing conventional tanks, well, maybe some sort of special form, due to constructional nuances, but no!

22.

A sense of humor, even at such a serious production must be present)

23.

Acceptance of work.

24.

Transportation fragment wing.

25.

26.

27.

Instead of lunch we go to look at the testing of ready-made aircraft. Again, verification of documents and a few minutes later we are on the field. At the start of preparing two cars, one had just stepped out of the stocks of the plant, the second is painted - this is her last test flight. She sits in the regiment assigned to it.

28.

Not yet fledgeling today he first tests. Many people mistakenly believe, since Soo -34 became mass-produced, what his experience in different modes? This view is fundamentally disagree factory - because during all the tests necessary to provide that pilots often fly to drill safely, confidently and safely!

29.

While I'm trying to keep warm in the freezing wind. This machine runs the latest preflight preparation. The pilots in the cockpit.

30.

Look professional with a capital letter. The guys know their stuff all 150 percent! By the way, they check the flight performance of the machine flying at extremely low and high altitudes, as much as possible in a supersonic mode. In these modes, in line units do not fly! We test pilot only 4 flight two hours factory pilots and 3 flight More pilots are already a customer.

31.

Before being tested by entrance of all wings and planes.

32.

So transported to the test one more car.

33.

Honored test pilot Valeriy Potashёv. He is now 66 years old, work experience Flight 43, just imagine how much you need to be strong in that 66 years have access to such in flights!

Valery Serpionovich said that in one test flight the machine tested 350 modes. Checks overall performance of the aircraft systems, engines and airborne radar equipment.

34.

35.

36.

Perhaps this is the most memorable, when the 7-10 meters away from me this machine thundered, bringing to the runway. The roar of the engines, and covers a second or two can not hear anything. Then, just before the takeoff, the Su-34 has cut the engines at full power. You would know how it is now loudly told us the officer standing beside ...

37.

New steel bird, having made a short run, sharply off the ground, and a few seconds later disappeared among low drifting clouds towards the sun, and to the place of their habitat.

End)