1113

How to make Christmas decorations (10 photos)

Very interesting and somehow festive welcome

-

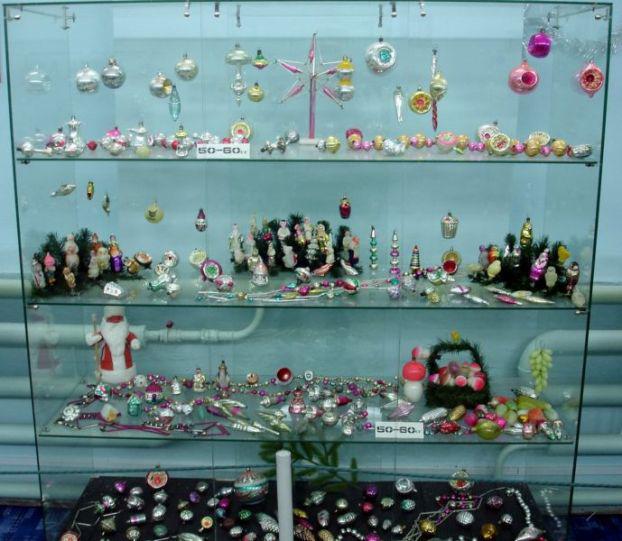

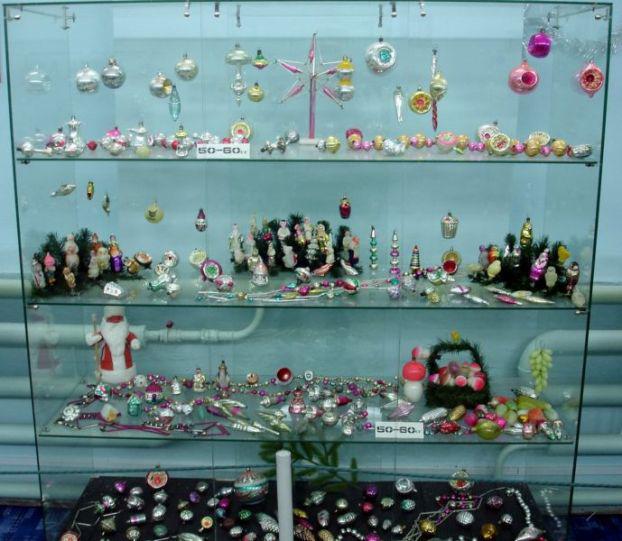

See a ball?

Now certainly read why this ball just have to decorate your Christmas tree.

You know how to make these balls?

Imagine the huge factory where puffing large machine spits out the same shiny balls, conveyor belt on which the travel then the balls that are super-modern sprayers poured paint balls go farther, passing in a special chamber, where all sides to them pshikat special trickle paint , causing a complex pattern. Then the balls down the pipeline, blown by the wind and fast drying. Finally, at the end of the conveyor neat rows fall into the boxes, sealable robot - a miracle of modern technology. Pick up a glass ball, made the company "Herringbone", look at him and feel that you are holding in your hands. Feel the soul, which has invested in Russian women, often with disabilities, which for many, many years working in the factory Christmas decorations, bringing the festival to every home. These people made the ball by hand. Entirely hand.

You know how to make these balls?

And I'll tell you. To you got sick to buy Chinese ugly plastic consumer goods.

I think it would be good if you tell your friends about it, and we all support the domestic manufacturer =)

from this building in the Klin district of Moscow region year-round make the tale. Year-round, except for one summer month (during maintenance work) are hard at work. Produces glass beads, tips for trees, curly toys and many more of all beauty.

By the end of the Soviet period in the factory automation equipment was imported, but it was not established, and in the period of economic decline in the 1990s, fell into disrepair.

Plant plunges into the atmosphere of "first five", and possibly the end of the 19th century. Christmas decorations are born in the most difficult conditions. In the stuffy rooms, in the hot air of small small rooms where blown glass forms, and it is impossible to spend fifteen minutes, and then the whole day working people.

Some older workers factory even frighten their grandchildren: "You will do poorly in school - you will go to work for" Christmas trees "!

The first shop of the factory - the hot shop. There in the shadows, noise and heat for 6-8 thousand a month working 50 women glassblowers blown by a gas burner, and its mouth of the glass tube blank toys. The working day lasts 8 hours. During this time, each worker must produce preforms 200-250 depending on the shape of the future toys.

The difficulty lies in the accuracy of manufacture: ball diameter, for example, must be observed up to 1-2 millimeters. If you get a little crooked, a ball thrown.

To become a good glassmaker, it is necessary to study for 6 months and not less than 2 years of work in the production.

Further, the workpiece balls fall in a special workshop where they are under a lot of pressure is applied to the aluminum cover. And simply put, the technology is such that the ball just reeled under the pressure of common foil layer.

If the ball then just do not cover paint, foil fall off.

Therefore, further balls arrive in the next shop, where they (each ball) women's hands dipped in large tanks with paint, then put to dry.

Dry balls here in these furnaces (see. Photo below). See: just sand, put balls on sticks. Each individual bead. Then each individual bead is removed and sent to the next department.

Here, all the toys paint the real masters. Manually. Sometimes the ball can go on for several hours or even a whole day, depending on the ease of drawing. Masters extremely lacking. Such learning is not easy craft.

For example, to paint a ball, the artist will take several hours.

And these balls - handmade actually because each of them is unique! Exclusive, sold for a hundred rubles. Foreigners take out the bulbs from the factory (when they come on the tour) bags - in Europe, such a miracle will cost several times, and even ten times more expensive.

And we do not appreciate ...

via souffrante

-

-

See a ball?

Now certainly read why this ball just have to decorate your Christmas tree.

You know how to make these balls?

Imagine the huge factory where puffing large machine spits out the same shiny balls, conveyor belt on which the travel then the balls that are super-modern sprayers poured paint balls go farther, passing in a special chamber, where all sides to them pshikat special trickle paint , causing a complex pattern. Then the balls down the pipeline, blown by the wind and fast drying. Finally, at the end of the conveyor neat rows fall into the boxes, sealable robot - a miracle of modern technology. Pick up a glass ball, made the company "Herringbone", look at him and feel that you are holding in your hands. Feel the soul, which has invested in Russian women, often with disabilities, which for many, many years working in the factory Christmas decorations, bringing the festival to every home. These people made the ball by hand. Entirely hand.

You know how to make these balls?

And I'll tell you. To you got sick to buy Chinese ugly plastic consumer goods.

I think it would be good if you tell your friends about it, and we all support the domestic manufacturer =)

from this building in the Klin district of Moscow region year-round make the tale. Year-round, except for one summer month (during maintenance work) are hard at work. Produces glass beads, tips for trees, curly toys and many more of all beauty.

By the end of the Soviet period in the factory automation equipment was imported, but it was not established, and in the period of economic decline in the 1990s, fell into disrepair.

Plant plunges into the atmosphere of "first five", and possibly the end of the 19th century. Christmas decorations are born in the most difficult conditions. In the stuffy rooms, in the hot air of small small rooms where blown glass forms, and it is impossible to spend fifteen minutes, and then the whole day working people.

Some older workers factory even frighten their grandchildren: "You will do poorly in school - you will go to work for" Christmas trees "!

The first shop of the factory - the hot shop. There in the shadows, noise and heat for 6-8 thousand a month working 50 women glassblowers blown by a gas burner, and its mouth of the glass tube blank toys. The working day lasts 8 hours. During this time, each worker must produce preforms 200-250 depending on the shape of the future toys.

The difficulty lies in the accuracy of manufacture: ball diameter, for example, must be observed up to 1-2 millimeters. If you get a little crooked, a ball thrown.

To become a good glassmaker, it is necessary to study for 6 months and not less than 2 years of work in the production.

Further, the workpiece balls fall in a special workshop where they are under a lot of pressure is applied to the aluminum cover. And simply put, the technology is such that the ball just reeled under the pressure of common foil layer.

If the ball then just do not cover paint, foil fall off.

Therefore, further balls arrive in the next shop, where they (each ball) women's hands dipped in large tanks with paint, then put to dry.

Dry balls here in these furnaces (see. Photo below). See: just sand, put balls on sticks. Each individual bead. Then each individual bead is removed and sent to the next department.

Here, all the toys paint the real masters. Manually. Sometimes the ball can go on for several hours or even a whole day, depending on the ease of drawing. Masters extremely lacking. Such learning is not easy craft.

For example, to paint a ball, the artist will take several hours.

And these balls - handmade actually because each of them is unique! Exclusive, sold for a hundred rubles. Foreigners take out the bulbs from the factory (when they come on the tour) bags - in Europe, such a miracle will cost several times, and even ten times more expensive.

And we do not appreciate ...

via souffrante

-