2519

1.7

2021-09-28

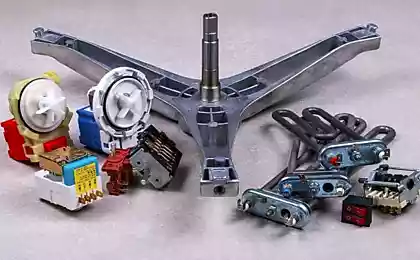

Things You Should Know About IDC Connectors

IDC or insulation-displacement contact is basically an electrical connector that connects itself to the conductor of an insulated cable through a specific connection process. It’s a very efficient way of shielding the conductor, and once the connection is made correctly, the conductor and IDC connector are supposed to have a gas-tight connection. Let’s learn more about it below.

How Do IDC Connectors Work?

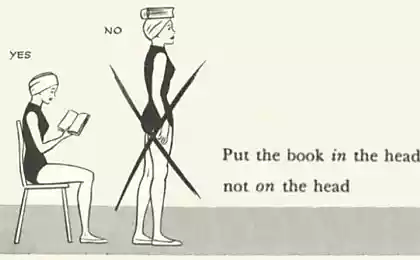

The procedure is quite simplistic. First, you need to connect the IDC connector to the conductor(s) of the insulated cable(s). Once the connection begins, selectively sharpened blade(s) go through the insulation and, if done correctly, will cold-weld the connector to the conductor.

IDC connector’s process is much easier and simpler because it will bypass the need to strip the conductor first and then connect them like the old times. This automated system makes the whole procedure simple and efficient.

Basic Information about IDC Connectors

IDC cable assemblies, including IDC connectors, come on 1.27 mm pitch, 2.00 mm pitch, and 2.54 mm pitch. While most of the connectors are double-row, some of the connectors are single-row as well.

IDC contacts are made from phosphor bronze materials and have a wire slot to match a specific wire gauge. While the blade is going through, it pierces and displaces the wire insulation completely, eliminating all stripping needs.

Why Are IDC Connectors So Popular?

IDC connectors are deemed much less expensive than other connectors, mainly because they’re faster and easier to manufacture. You get to terminate a dozen wires and contacts with it effortlessly. You don’t need to solder, crimp or strip the insulations before termination; it’s an automated process and saves a lot of money and time.

You can terminate most kinds of IDC’s using any simple tool or even by a bare hand press. Unlike other connectors, way less force is required to cease the ribbon cable to IDC contacts.

They are often vibration-proof and gas-tight if installed correctly. If you’re buying IDC connectors from a reputed company, then a reliable connection is guaranteed.

Issues with IDC Connectors

The main problem with ribbon cables and IDC connectors is that the cable is quite stiff and inflexible. So, you won’t get a lot of bends and angles from it. If you’re working with tight angles, then maybe using IDC connectors won’t be a very smart idea for you.

Портал БАШНЯ. Копирование, Перепечатка возможна при указании активной ссылки на данную страницу.