1079

Compressed Air Energy Storage (CAES) - Air Battery

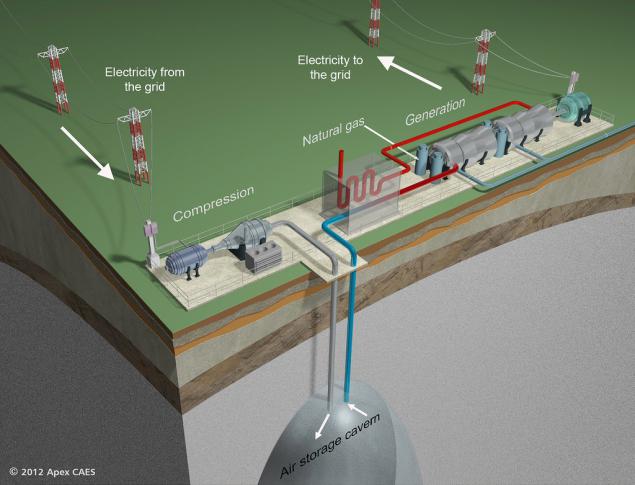

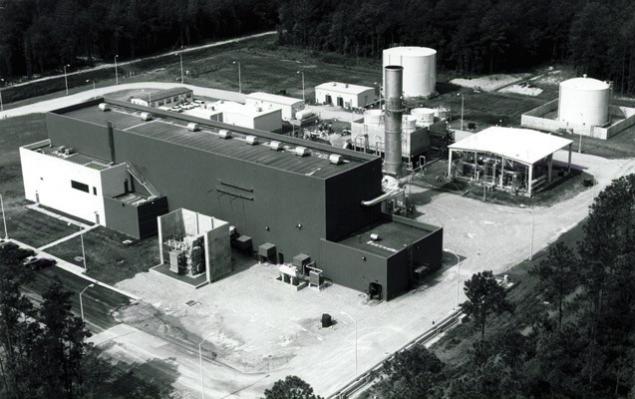

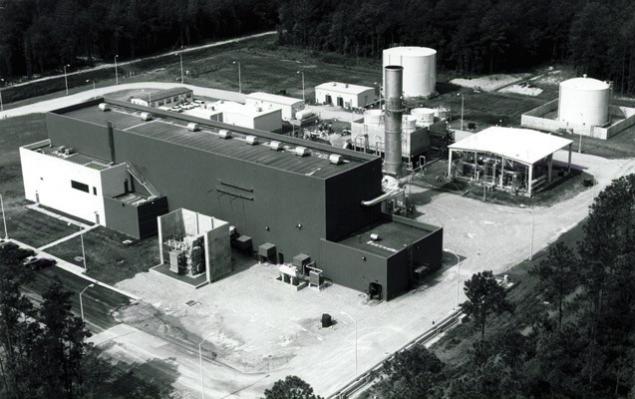

Cave, compressor and gas turbine - so made the pneumatic energy accumulator. In the US, the first such device was built in 1991 in the Mclntosh, Alabama. Its purpose - to peak shaving power.

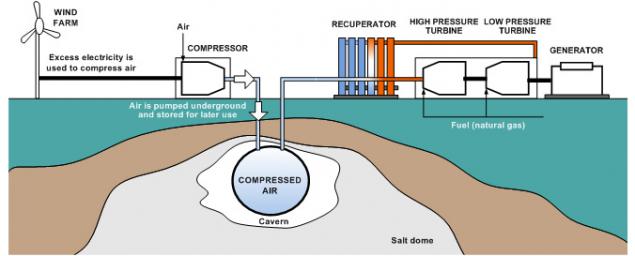

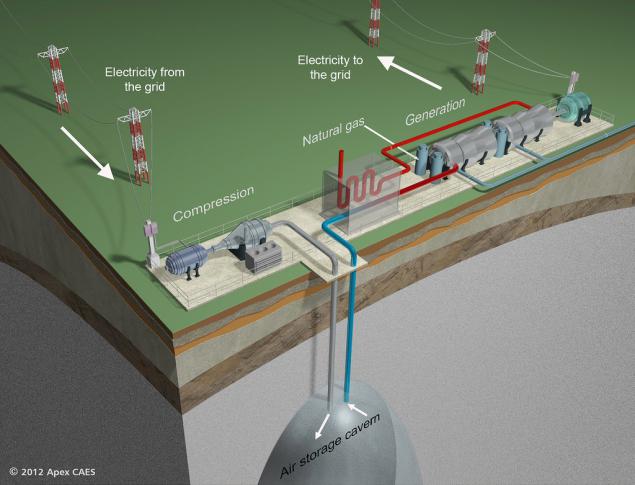

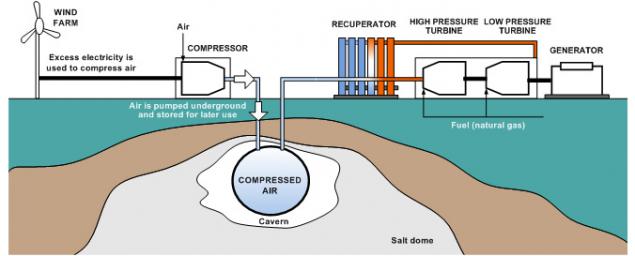

Air compressors driven into underground storage (natural salt cave) in volume 538 cubic meters up to a pressure of 77 atm. When the power consumption in the network suddenly increases, the air goes in and sends a power system.

Emptying the tank to lower the operating pressure 46 atm - 26 hours, during which the station gives 110 MW.

The compressed air turns the turbine itself, and enters the gas turbine. Since usually 2/3 power of the gas turbine is consumed to drive a compressor which pumps air into it, it turns solid savings. Before entering the turbine air is heated in the flow heat recovery (recuperator) combustion, which adds efficiency.

Celebrating decrease gas consumption by 60 ... 70% compared to conventional gas turbine, quick start from cold (a few minutes ) and a good job at low loads.

The project in Alabama is not unique. Back in 1978, the Germans launched Huntorf store 290 MW (2 hours operation) in two salt caverns located at a depth of 600 ... 800 m with a pressure range of 50 ... 70 bar. Originally it served as a hot standby repository for the industry of North-West Germany, and is now used to smooth the peaks of wind power generation.

Write , that in the Donets Basin during the Soviet planned improvement in the same cave air battery 1050 MW; Unfortunately, his fate is unknown.

In 2012 in Texas near the 2-megawatt wind farm was opened pneumatic storage 500 MWh, but specifics for it is not enough.

Приводят the overall efficiency of such stations 41 ... 53% and indicate , that the cost of construction is $ 360 ... 650 / kW or more, depending on whether you use a natural cave, or you have to dig new.

However, you can do without caverns and store energy in the bags at the bottom of the sea .

Source: geektimes.ru/post/249188/

Air compressors driven into underground storage (natural salt cave) in volume 538 cubic meters up to a pressure of 77 atm. When the power consumption in the network suddenly increases, the air goes in and sends a power system.

Emptying the tank to lower the operating pressure 46 atm - 26 hours, during which the station gives 110 MW.

The compressed air turns the turbine itself, and enters the gas turbine. Since usually 2/3 power of the gas turbine is consumed to drive a compressor which pumps air into it, it turns solid savings. Before entering the turbine air is heated in the flow heat recovery (recuperator) combustion, which adds efficiency.

Celebrating decrease gas consumption by 60 ... 70% compared to conventional gas turbine, quick start from cold (a few minutes ) and a good job at low loads.

The project in Alabama is not unique. Back in 1978, the Germans launched Huntorf store 290 MW (2 hours operation) in two salt caverns located at a depth of 600 ... 800 m with a pressure range of 50 ... 70 bar. Originally it served as a hot standby repository for the industry of North-West Germany, and is now used to smooth the peaks of wind power generation.

Write , that in the Donets Basin during the Soviet planned improvement in the same cave air battery 1050 MW; Unfortunately, his fate is unknown.

In 2012 in Texas near the 2-megawatt wind farm was opened pneumatic storage 500 MWh, but specifics for it is not enough.

Приводят the overall efficiency of such stations 41 ... 53% and indicate , that the cost of construction is $ 360 ... 650 / kW or more, depending on whether you use a natural cave, or you have to dig new.

However, you can do without caverns and store energy in the bags at the bottom of the sea .

Source: geektimes.ru/post/249188/