1135

With nanofrezera IBM created the world's smallest magazine cover

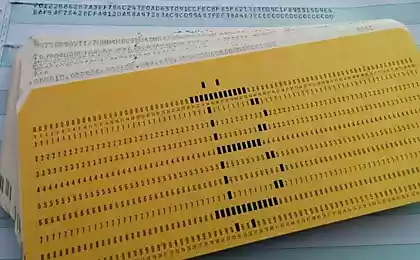

Cover of the magazine National Geographic Kids has dimensions of just 11h14 micrometers. Record miniaturization officially recorded representatives of Guinness World Records. Browse the cover can only through an electron microscope, optical can only see blurred outlines. Resolution milling machine, with which was engraved cover - 8 nanometers. This is several times less than the most advanced fabrication process of integrated circuits. On the creation of copies of the cover took 10 minutes.

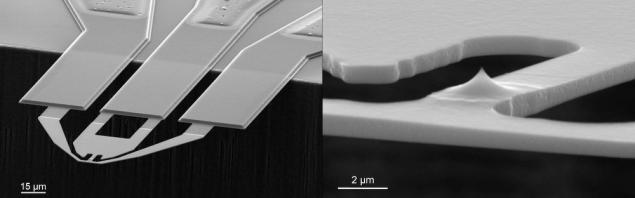

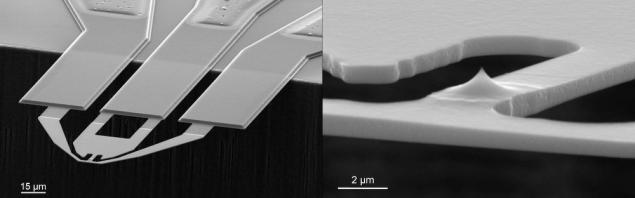

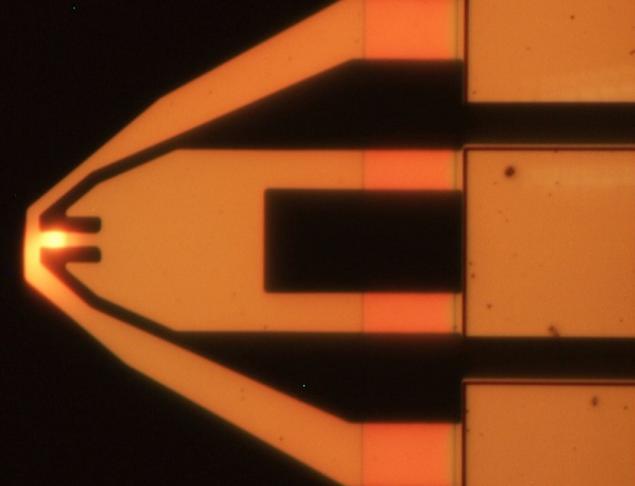

Nanofrezer developed in the laboratories of IBM Research in Zurich, and its commercial promotion company engaged SwissLitho AG, founded in 2012. Cutter nanofrezera a silicon tip diameter of 12 nanometers, which is heated to 1000 degrees, and vaporizes the plastic below it. Subsequently, on the etched in plastic structures may be deposited other materials, creating microelectronic devices.

The list of possible applications mill on the site has about 20 SwissLitho examples. Here are just a few of them. Nanofrezer can use to create optichesikh devices - microlens diffraction gratings, Fresnel lenses at the nanoscale. It can be used as a "plotter" for graphene. With it convenient to create microelectromechanical systems - gyroscopes, accelerometers, etc. It creates nanostructures can be used as templates for the self-assembly of nanostructures or work with living cells in medicine and biology.

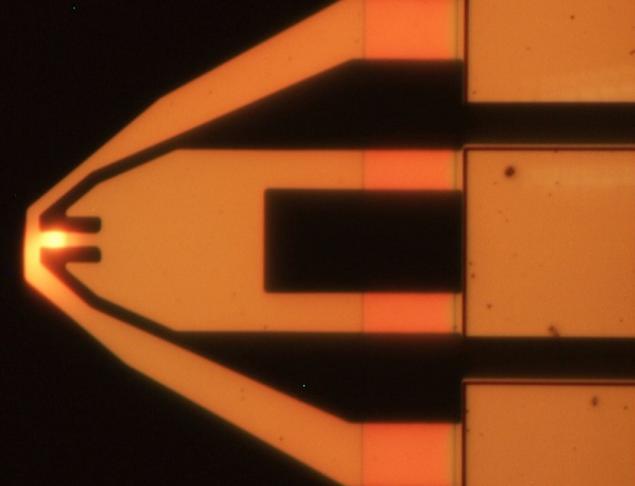

Cutter warmed up to operating temperature. I>

Another use case - system backup and archiving high reliability. Very fine control over the depth of etching to achieve high recording density - at one point two-dimensional plate or disc can be recorded much more than one bit of information. Created engraver plastic substrate can then cover with silicon - the recording will literally carved in stone and can be stored for centuries.

Generally nanofrezer by the abundance of its applications and flexibility can be compared to 3D-prinetrom only working on a microscopic level. It can be used for prototyping and experimentation wherever needed nanometer accuracy. So far, the router offers SwissLitho NanoFrazor explore for this purpose. At the 2016-17 year is planned to create router industrial scale - it instead of one incisor is involved the whole array, and you can get instead of a single product or a few hundred thousand in one go.

Sources: блог IBM Research , SwissLitho.com

Source: habrahabr.ru/post/220905/

Nanofrezer developed in the laboratories of IBM Research in Zurich, and its commercial promotion company engaged SwissLitho AG, founded in 2012. Cutter nanofrezera a silicon tip diameter of 12 nanometers, which is heated to 1000 degrees, and vaporizes the plastic below it. Subsequently, on the etched in plastic structures may be deposited other materials, creating microelectronic devices.

The list of possible applications mill on the site has about 20 SwissLitho examples. Here are just a few of them. Nanofrezer can use to create optichesikh devices - microlens diffraction gratings, Fresnel lenses at the nanoscale. It can be used as a "plotter" for graphene. With it convenient to create microelectromechanical systems - gyroscopes, accelerometers, etc. It creates nanostructures can be used as templates for the self-assembly of nanostructures or work with living cells in medicine and biology.

Cutter warmed up to operating temperature. I>

Another use case - system backup and archiving high reliability. Very fine control over the depth of etching to achieve high recording density - at one point two-dimensional plate or disc can be recorded much more than one bit of information. Created engraver plastic substrate can then cover with silicon - the recording will literally carved in stone and can be stored for centuries.

Generally nanofrezer by the abundance of its applications and flexibility can be compared to 3D-prinetrom only working on a microscopic level. It can be used for prototyping and experimentation wherever needed nanometer accuracy. So far, the router offers SwissLitho NanoFrazor explore for this purpose. At the 2016-17 year is planned to create router industrial scale - it instead of one incisor is involved the whole array, and you can get instead of a single product or a few hundred thousand in one go.

Sources: блог IBM Research , SwissLitho.com

Source: habrahabr.ru/post/220905/