811

The ring for the beloved - handmade from A to Z

Writes Sanchezz with BMW Forum Club

In December last year, I decided to collect the jewelry workshop. Acquired workbench, tools, appliances, etc. ... all "business", so first of all to have been a pleasure to work.

In the early '90s I went to the jeweler's disciples, then studied at the painter. department, then a few years taught yuvelirku and all this time (around 12-14 years); Job wizard.

Then they all got tired and I "gave up". I sold or gave away everything I had: tools and equipment. He got a job as an apprentice manager, manager, chief of the department, to the ... gene. Director, Founder .... And it's not yuvelirka.

Yuvelirka for the soul and for the joy of family, thank God there is a skill, and in good shape.

44 photos

I truant somehow my wife shopping. I saw the ring, "turban" and wanted it. She called me in there and looked. I said I could do that, but at that time the workshop was not yet operational. BUT. The man said- man made.

The prototype of the product was photographed by the wife to mobile. Photos are not so hot, but I was so clear what to do and how.

02

03

04

Task given. Next, for the work!

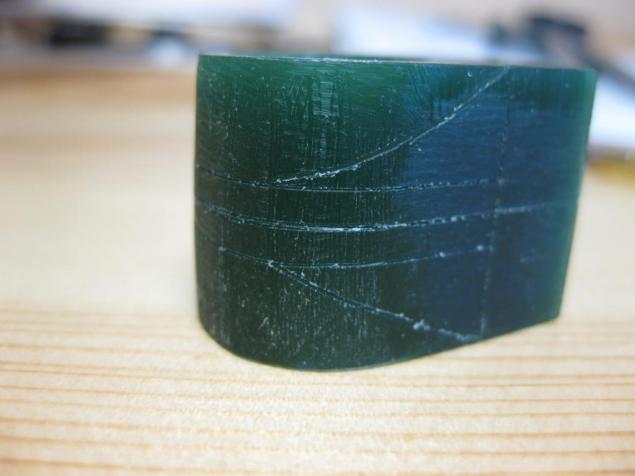

Beru modeling wax. I saw off a piece of it, mark and raced!

06

07

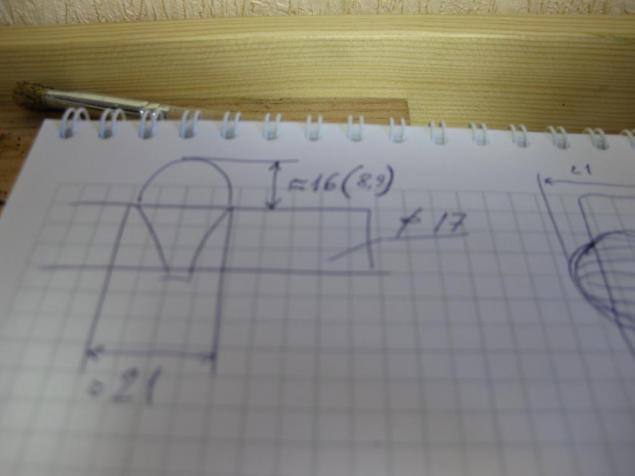

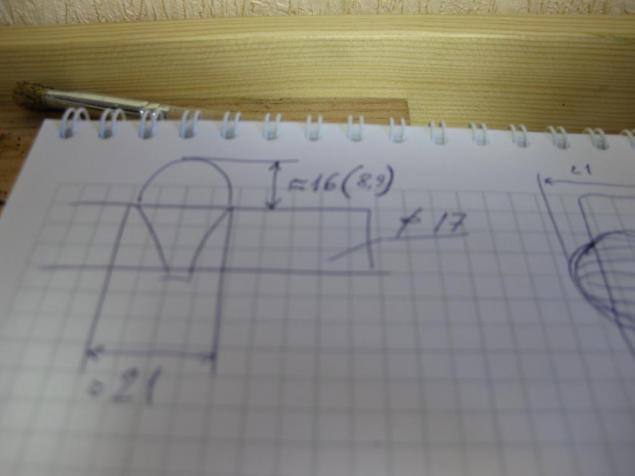

Type sketch. Some products I make the great Gaudi. Sketches and drawings in my head. ))

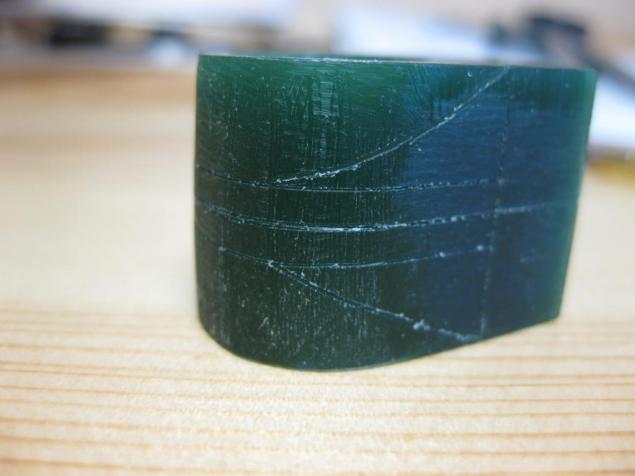

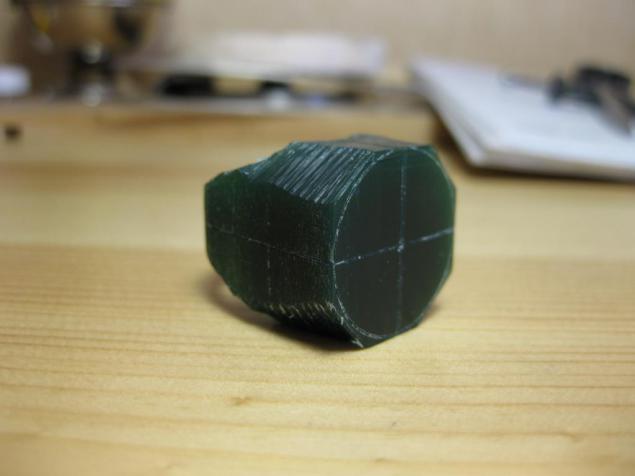

Partitioning is done. I began to nag. Removes superfluous. So far, roughly.

Oststki from past victories (past life).

11

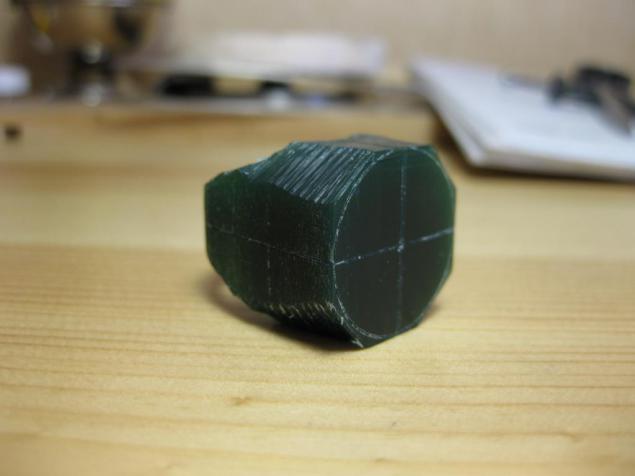

That such blanks (of modeling wax) made about 100% of the total sold in the moment yuvelirki

What is already beginning to look like

Straško

That this knife, called a "scraper" and made in Switzerland, I give shape to the product. Chambray so to speak. The ball turns

Oh, how long before the finished product

Further processing technology is the removal of excess material and giving the most correct, the desired shape before the next process step: casting, investment casting.

Here they are - "a jeweler's best friend" marker compasses, scraper, sketch ...

At this point, for some reason I stopped photographing. And then it was the application of ribs, an undercut (remove wax from the inside of the ring) and the preparation for casting.

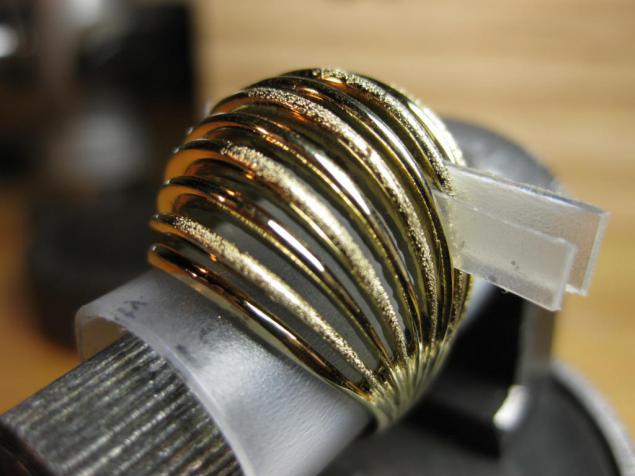

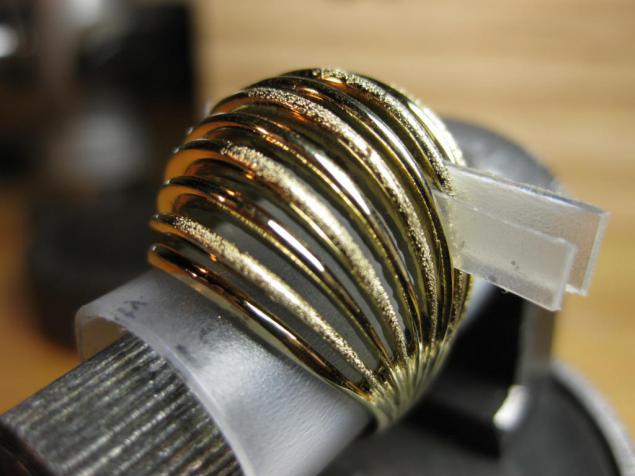

Cast. All qualitatively. That's how it looks. Yellow gold 585.

20

21

This is a terrible thing, in the foreground, called the "gate." Through it melted Zsolt poured into the mold, which was formerly a stencil, which I did, and just before the casting was a void there that mimic frmu wax. Here.

23

The blank must be "anneal". Ie heated to a temperature of about 750-800 degrees, under a layer of protective flux. It is necessary to remove the internal stresses in the metal and normalize the crystal structure. Although it is the same thing.

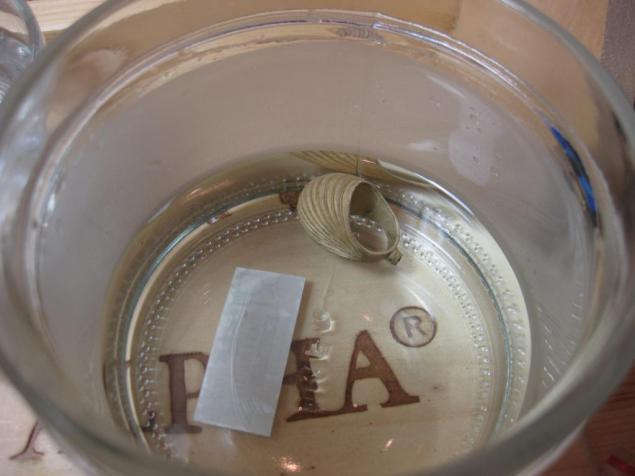

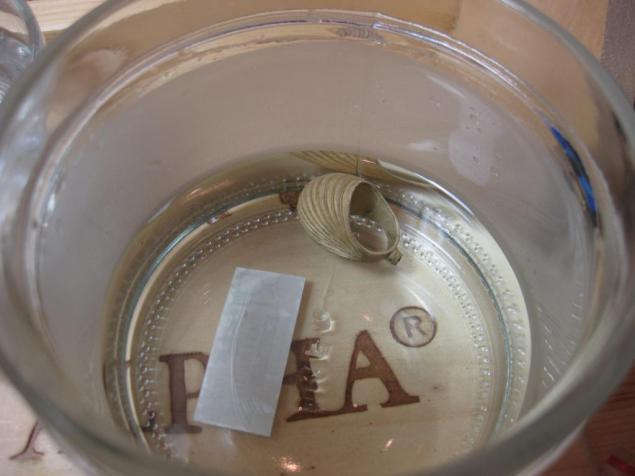

After annealing, the preform is placed into the acid. The procedure is known as "bleaching."

At this point begins machining products. Tools that are used are different. The internal surface of a processing mills. Outdoor jigsaw, Needle, graver. All of this, I'll show you. Handling products in the metal - Responsibility process. You can not make mistakes, as some of them may not be repairable. The accuracy of eye and hand hardness - that's my motto!

Processed file.

Make a well jigsaw. In the future, there will be full cuts

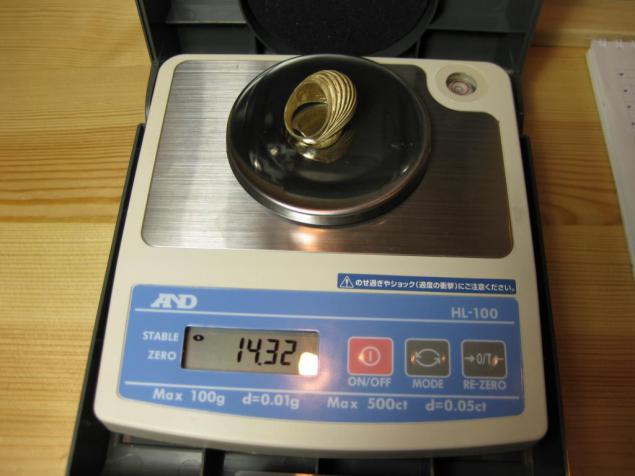

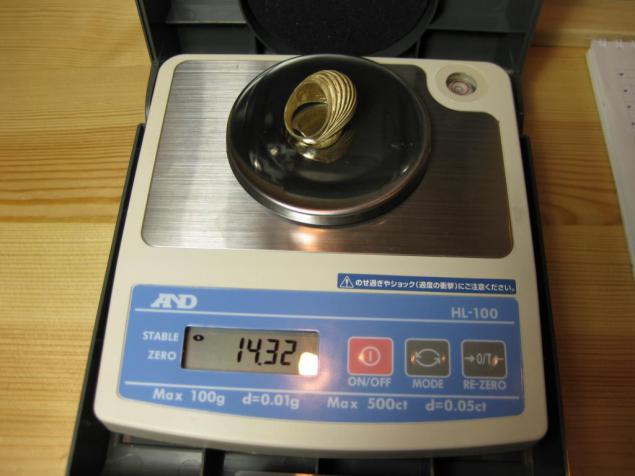

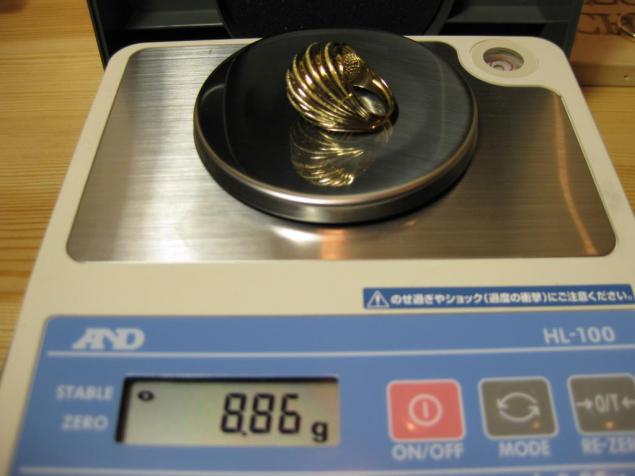

Note the weight of the preform.

Propylene.

Here are a bunch of gold, I sawed. And that's not all.

All lies in a metal pan.

This nadfilkom Peel. Others will be too.

Shaping far from complete.

This table entitled "Letkal" comes soldering products, and all that is connected with the high-temperature heating. Temperature in the processing of gold is in the range 700-1100 degrees Celsius. In the foreground are visible square pieces of gold solder. According to the technology part of the jewelry, the color of the sample and the solder must meet the basic metal (from which the product is made).

In this photo you can see that I put a thin gold plates in the place too deep cuts, and going to solder them.

Done!

The beautiful yellow color. YaMne some reason do not like pink "Sovestky" gold.

Inside all unnecessary selected and applied to the invoice. Fakturka applied cutter, with a diameter of 1 mm. Imagine how many times you need to attach to metal cutter ???

Well, I start to give final shape. Files With almost finished. Grinding. Here in the case are special grinding wheels and sandpaper. Everything is done handles. This product warmth of my hands!

All rovnenko. Well, I do know that there are errors. Do not worry - this is handmade.

All polished and ready to be polished.

Polirnul! I put a ring on the polishing brush. I think a good natyurmorchik work?

To correctly apply fakturku finish required on the edges in one. Fakturka similar preparedness or on the golden sand or a sugar dusting (well, I think so) Here's how: in his right hand a little stamping hammer, chisel in his left hand. Each flyspeck applied separately. They eventually several thousand.

Oh, I forgot to say. The product is attached to a special vice, which rotate in all directions if necessary. And in the jargon of jewelers called "Sharobubel." Under article placed a thick polyethylene which dampens shock and prevents scratching polished inside.

Between the ribs also paved pads to increase the overall stiffness of the top products in the coinage. Even so chasing is a shock. The deformation of the top I do not need. To finish hand. I work very carefully and cautiously. I will say that the application of texture in this case is very time-consuming and tedious. In the real world it took almost the whole day

That's what happens.

Total

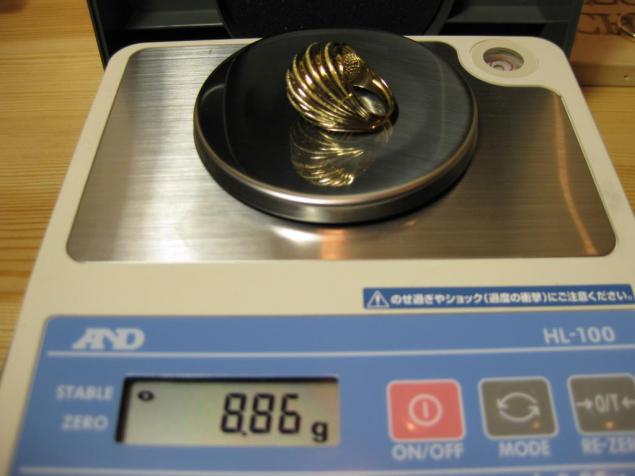

We look at the finished product weight and remember the weight of the workpiece))

Source:

In December last year, I decided to collect the jewelry workshop. Acquired workbench, tools, appliances, etc. ... all "business", so first of all to have been a pleasure to work.

In the early '90s I went to the jeweler's disciples, then studied at the painter. department, then a few years taught yuvelirku and all this time (around 12-14 years); Job wizard.

Then they all got tired and I "gave up". I sold or gave away everything I had: tools and equipment. He got a job as an apprentice manager, manager, chief of the department, to the ... gene. Director, Founder .... And it's not yuvelirka.

Yuvelirka for the soul and for the joy of family, thank God there is a skill, and in good shape.

44 photos

I truant somehow my wife shopping. I saw the ring, "turban" and wanted it. She called me in there and looked. I said I could do that, but at that time the workshop was not yet operational. BUT. The man said- man made.

The prototype of the product was photographed by the wife to mobile. Photos are not so hot, but I was so clear what to do and how.

02

03

04

Task given. Next, for the work!

Beru modeling wax. I saw off a piece of it, mark and raced!

06

07

Type sketch. Some products I make the great Gaudi. Sketches and drawings in my head. ))

Partitioning is done. I began to nag. Removes superfluous. So far, roughly.

Oststki from past victories (past life).

11

That such blanks (of modeling wax) made about 100% of the total sold in the moment yuvelirki

What is already beginning to look like

Straško

That this knife, called a "scraper" and made in Switzerland, I give shape to the product. Chambray so to speak. The ball turns

Oh, how long before the finished product

Further processing technology is the removal of excess material and giving the most correct, the desired shape before the next process step: casting, investment casting.

Here they are - "a jeweler's best friend" marker compasses, scraper, sketch ...

At this point, for some reason I stopped photographing. And then it was the application of ribs, an undercut (remove wax from the inside of the ring) and the preparation for casting.

Cast. All qualitatively. That's how it looks. Yellow gold 585.

20

21

This is a terrible thing, in the foreground, called the "gate." Through it melted Zsolt poured into the mold, which was formerly a stencil, which I did, and just before the casting was a void there that mimic frmu wax. Here.

23

The blank must be "anneal". Ie heated to a temperature of about 750-800 degrees, under a layer of protective flux. It is necessary to remove the internal stresses in the metal and normalize the crystal structure. Although it is the same thing.

After annealing, the preform is placed into the acid. The procedure is known as "bleaching."

At this point begins machining products. Tools that are used are different. The internal surface of a processing mills. Outdoor jigsaw, Needle, graver. All of this, I'll show you. Handling products in the metal - Responsibility process. You can not make mistakes, as some of them may not be repairable. The accuracy of eye and hand hardness - that's my motto!

Processed file.

Make a well jigsaw. In the future, there will be full cuts

Note the weight of the preform.

Propylene.

Here are a bunch of gold, I sawed. And that's not all.

All lies in a metal pan.

This nadfilkom Peel. Others will be too.

Shaping far from complete.

This table entitled "Letkal" comes soldering products, and all that is connected with the high-temperature heating. Temperature in the processing of gold is in the range 700-1100 degrees Celsius. In the foreground are visible square pieces of gold solder. According to the technology part of the jewelry, the color of the sample and the solder must meet the basic metal (from which the product is made).

In this photo you can see that I put a thin gold plates in the place too deep cuts, and going to solder them.

Done!

The beautiful yellow color. YaMne some reason do not like pink "Sovestky" gold.

Inside all unnecessary selected and applied to the invoice. Fakturka applied cutter, with a diameter of 1 mm. Imagine how many times you need to attach to metal cutter ???

Well, I start to give final shape. Files With almost finished. Grinding. Here in the case are special grinding wheels and sandpaper. Everything is done handles. This product warmth of my hands!

All rovnenko. Well, I do know that there are errors. Do not worry - this is handmade.

All polished and ready to be polished.

Polirnul! I put a ring on the polishing brush. I think a good natyurmorchik work?

To correctly apply fakturku finish required on the edges in one. Fakturka similar preparedness or on the golden sand or a sugar dusting (well, I think so) Here's how: in his right hand a little stamping hammer, chisel in his left hand. Each flyspeck applied separately. They eventually several thousand.

Oh, I forgot to say. The product is attached to a special vice, which rotate in all directions if necessary. And in the jargon of jewelers called "Sharobubel." Under article placed a thick polyethylene which dampens shock and prevents scratching polished inside.

Between the ribs also paved pads to increase the overall stiffness of the top products in the coinage. Even so chasing is a shock. The deformation of the top I do not need. To finish hand. I work very carefully and cautiously. I will say that the application of texture in this case is very time-consuming and tedious. In the real world it took almost the whole day

That's what happens.

Total

We look at the finished product weight and remember the weight of the workpiece))

Source: