346

"Canon 5D" foam

I work for a company that produces equipment for cutting foam polystyrene (foam to put it simply).

The idea was in the air of our office a couple of years, but finally formed only on the eve of the New 2014 - it is necessary to make a project that will be able to show the process of creating a model from scratch foam. Before we cut out all sorts of products exclusively for demonstration of capabilities of the machine. But usually that is not enough, the buyer wants the machine to understand the quality of the final product which it will offer in the market.

Will 29 photo source.

Experience in bringing the product to the end of the form we have virtually no, which made the project even more interesting - the knowledge and experience in this industry, we will not interfere. Preparing Files cutting itself manufacture the layout we have undertaken. Lapping and painting given to our colleagues.

It is thought to cut the camera did not come immediately. There were different ideas - iPhone, Keychain from car alarms, iron, etc. From iPhone abandoned because too easy. Brick it is a brick. I wanted something more sophisticated and visually familiar to everyone. As a result, conferred on the camera stopped.

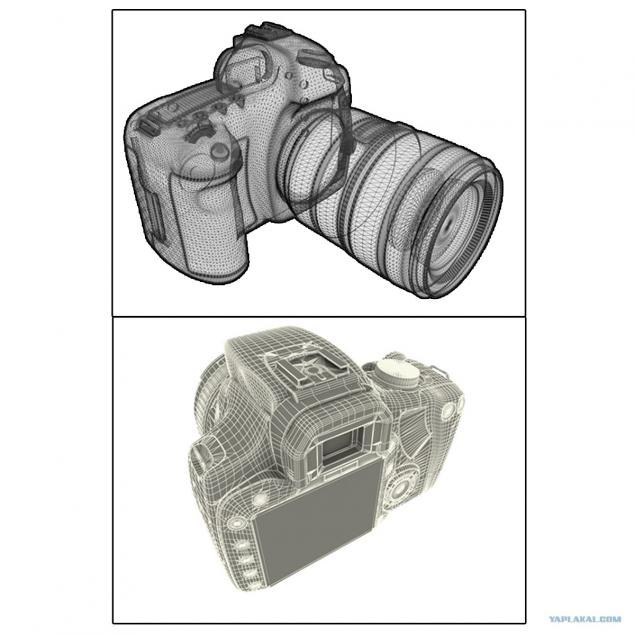

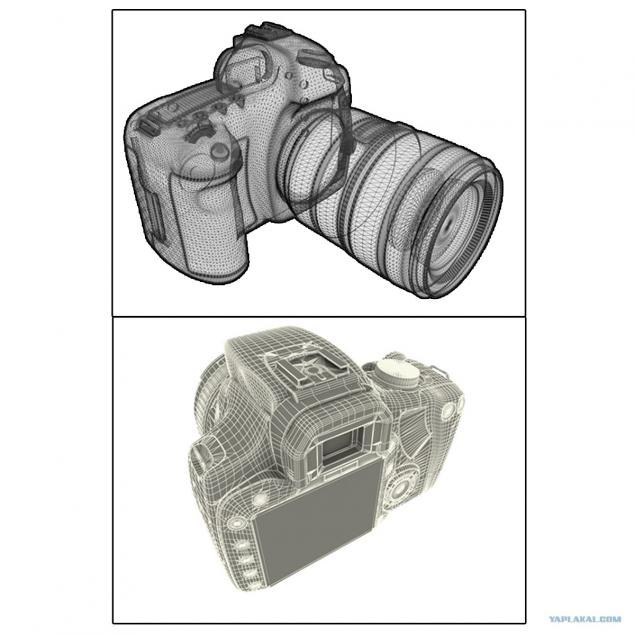

Aims to cut a specific model was not, it does not matter «Canon», «Nikon» or «Sony». Repellent based on the quality of existing 3D models.

In the course of the briefings made a check list:

1. Preparing Files cutting (STL)

2. Cutting

3. Pre-assembly, bonding

4. lapping, polishing, painting

In the first phase it took total to 11 hours. Camera dissected to separate elements 53, 53 respectively, making a file in STL format.

As time goes by, it's time to start:

We start cutting "carcass»

Cutting carcasses

By going to a small

Yet glued parts :)

More

Build housing

Fas

The entire cutting took 29 hours 41 minutes 30 seconds. In general, the process is not dusty, main properly position the workpiece relative to the center of the turntable. Recess on the front of the lens under the glass made using the extra set. equipment.

Yes to make the design more rigid lens and the "carcass" of the camera connected by metal pins, gluing detail makes liquid nails. Once all the details was ready, buttons and glued the whole model is assembled, a pig taken to our colleagues in the manual finishing, coating and painting dvuhkomponetnym polymer. Unfortunately, the whole process of fine-tuning is not captured, it was not possible to constantly go to the shop where the work was carried out ...

Grind, shpatlyuem ...

Application dvuhkomponetnogo polymer (urea)

On the other hand

The process of priming the shot did not hit, go for painting

Lens painted and waiting pasting Oracle

Same with "carcass»

Once all elements are painted, the foam is protected from environmental polymer sticker glued camera goes back to our production. Especially for the camera has been made with stepping divzhkom tripod on which he is destined to rotate in the exhibition "SibAdvertising" which opened on March 25 at the "Siberian Fair" in Novosibirsk.

The long-awaited moment :)

yt

Almost got :)

But it is on the very tripod. The exhibition will be closed advertising

More

Sensitively close

Labels screen is incidentally very realistic look from afar

Source:

The idea was in the air of our office a couple of years, but finally formed only on the eve of the New 2014 - it is necessary to make a project that will be able to show the process of creating a model from scratch foam. Before we cut out all sorts of products exclusively for demonstration of capabilities of the machine. But usually that is not enough, the buyer wants the machine to understand the quality of the final product which it will offer in the market.

Will 29 photo source.

Experience in bringing the product to the end of the form we have virtually no, which made the project even more interesting - the knowledge and experience in this industry, we will not interfere. Preparing Files cutting itself manufacture the layout we have undertaken. Lapping and painting given to our colleagues.

It is thought to cut the camera did not come immediately. There were different ideas - iPhone, Keychain from car alarms, iron, etc. From iPhone abandoned because too easy. Brick it is a brick. I wanted something more sophisticated and visually familiar to everyone. As a result, conferred on the camera stopped.

Aims to cut a specific model was not, it does not matter «Canon», «Nikon» or «Sony». Repellent based on the quality of existing 3D models.

In the course of the briefings made a check list:

1. Preparing Files cutting (STL)

2. Cutting

3. Pre-assembly, bonding

4. lapping, polishing, painting

In the first phase it took total to 11 hours. Camera dissected to separate elements 53, 53 respectively, making a file in STL format.

As time goes by, it's time to start:

We start cutting "carcass»

Cutting carcasses

By going to a small

Yet glued parts :)

More

Build housing

Fas

The entire cutting took 29 hours 41 minutes 30 seconds. In general, the process is not dusty, main properly position the workpiece relative to the center of the turntable. Recess on the front of the lens under the glass made using the extra set. equipment.

Yes to make the design more rigid lens and the "carcass" of the camera connected by metal pins, gluing detail makes liquid nails. Once all the details was ready, buttons and glued the whole model is assembled, a pig taken to our colleagues in the manual finishing, coating and painting dvuhkomponetnym polymer. Unfortunately, the whole process of fine-tuning is not captured, it was not possible to constantly go to the shop where the work was carried out ...

Grind, shpatlyuem ...

Application dvuhkomponetnogo polymer (urea)

On the other hand

The process of priming the shot did not hit, go for painting

Lens painted and waiting pasting Oracle

Same with "carcass»

Once all elements are painted, the foam is protected from environmental polymer sticker glued camera goes back to our production. Especially for the camera has been made with stepping divzhkom tripod on which he is destined to rotate in the exhibition "SibAdvertising" which opened on March 25 at the "Siberian Fair" in Novosibirsk.

The long-awaited moment :)

yt

Almost got :)

But it is on the very tripod. The exhibition will be closed advertising

More

Sensitively close

Labels screen is incidentally very realistic look from afar

Source: