534

Recommendations on use of sealed lead acid batteries

Sealed lead batteries are normally manufactured by two technologies — gel and AGM. The article further discussed the differences and characteristics of these two technologies. This General guidance manual for these batteries.

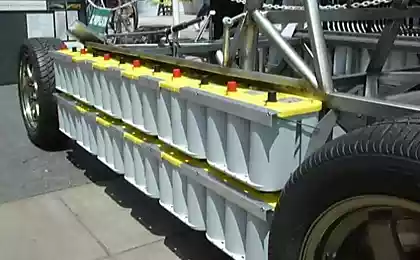

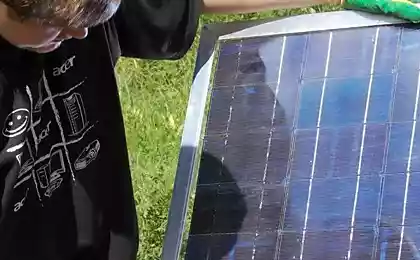

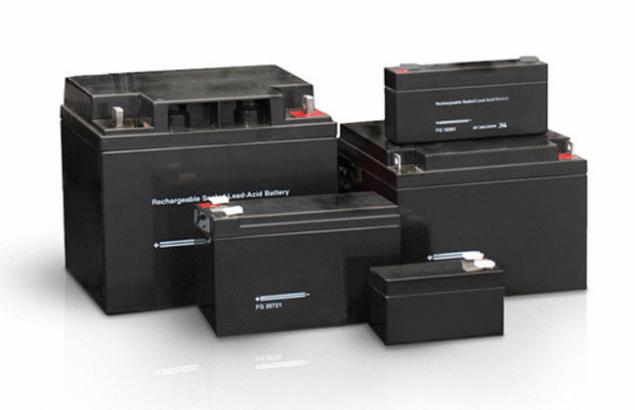

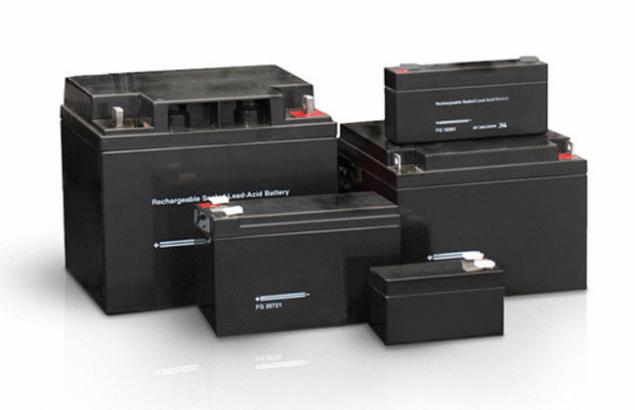

The main types of batteries recommended for use in stand-alone solar power systems: an Integral component of Autonomous solar energy systems are maintenance free batteries with high capacity. Such battery guarantee consistent quality and functional capabilities throughout the entire stated life cycle.

Technology AGM (Absorbent Glass Mat) In the Russian language it can be translated as “absorptive glass”. The electrolyte is also used acid in liquid form. But the space between the electrodes filled with a microporous material separator based on optical fiber. This substance acts like a sponge, it completely sucks all of the acid and keeps it, not allowing to spread.

When a chemical reaction inside a battery are also formed gases (mainly hydrogen and oxygen, their molecules are the constituent parts of water and acid). Their bubbles fill some of the pores, the gas does not escape. He is directly involved in chemical reactions when charging the battery, returning back into the liquid electrolyte. This process is called gas recombination. From the school chemistry course is known that a circular process may not be 100% effective. But in today's AGM batteries, the recombination efficiency reaches 95-99%. Ie inside the case of such a battery is formed negligible amounts of free unwanted gas and the electrolyte does not change its chemical properties for many years. However, after a very long time the free gas inside the battery creates excess pressure, when it reaches a certain level, that triggers a special exhaust valve. This valve also protects the battery from bursting in case of emergency situations: work in extreme conditions, a sharp increase in indoor temperature due to external factors and the like.

The main advantage of AGM batteries to a light GEL is lower the internal resistance of the battery. First of all, it affects the charge time of the battery, which in Autonomous systems is very limited, especially in winter. Thus, the AGM battery is charged faster, which means faster out of the mode of deep discharge, which, obviously, for both types of battery. If the system is Autonomous, that when using the AGM battery, its efficiency will be higher than the same system with battery GEL, because the GEL battery requires more time and power, which may not be enough on cloudy winter days. At low temperatures, gel battery, retains more capacity and is more stable, but as practice shows, in cloudy weather at low charge currents and low temperatures, a gel battery will not charge due to high internal resistance and "stiff" gel electrolyte while AGM battery will be charged by low current charging.

Special maintenance of AGM batteries is not required. Battery manufactured according to AGM technology maintenance-free and extra ventilation. Cheap AGM battery will work well in buffer mode with the depth of discharge of 20%. In this mode serve to 10-15 years.

If their use in a cyclic mode and discharged to at least 30-40%, their lifespan is significantly reduced. The AGM batteries are often used in inexpensive bespereboynik (UPS) and a small stand-alone solar power systems. However, in recent times, there are AGM batteries that are designed for deeper discharges and cyclic modes of operation. Of course, its characteristics are inferior to the GEL battery, but work fine in standalone solar power systems.

But the main technical feature of AGM batteries, unlike standard lead-acid battery, — ability to work in a mode of deep discharge. Ie, they can give electric energy for a long time (hours or even a day) to the point where the energy drops to 20-30% of the initial value. After the charging of such a battery it is almost completely restores its working capacity. Of course, it is completely such a situation can not take place. But the modern AGM batteries can withstand from 600 and above the cycles of deep discharge.

In addition, AGM batteries have very low current self-discharge. A charged battery can be stored unconnected for a long time. For example, over 12 months of inactivity the battery power drops to only 80% of the original. AGM batteries usually have a maximum allowed charge current 0.3 s, and the final charge voltage 15-16V. Such characteristics are achieved not only due to the design features of AGM technology. In the manufacture of batteries used more expensive materials with special properties: electrodes are made from ultra-pure lead, the electrodes do thicker, the electrolyte includes sulfuric acid of high purity.

Technology GEL — ( Gel Electrolite) In liquid electrolyte add material based on silicon dioxide (SiO2), resulting in a thick mass, resembling the consistency of jelly. This mass and filled the space between the electrodes inside the battery. In the process of chemical reactions in the bulk electrolyte there are numerous gas bubbles. These then sinks and encounters of the molecules of hydrogen and oxygen, i.e. gas recombination.

Unlike AGM technology gel batteries better yet recover from deep discharge even when the charging process is not started immediately after charging the battery. They can survive more than 1000 cycles of deep discharge without fundamental loss of its capacity. Since the electrolyte is in a dense condition, it is less susceptible to separation into constituent parts, water and acid, so gel batteries are more resistant to bad parameters of the current float charge.

Perhaps the only disadvantage of the gel technology is the price, it is higher than the AGM batteries of the same capacity. Therefore, use of gel batteries is recommended in complex and expensive systems of Autonomous and reserve electricity. And in cases where disconnection of the external electrical network, with enviable periodicity. Battery GEL better withstand cyclic charge-discharge. Also, they seem to tolerate extreme cold. Reducing capacitance by lowering the temperature of the battery is also smaller than other battery types. More preferably in power systems, when the batteries operate in cyclic modes (charged and discharged every day) and there is no way to maintain the temperature of the batteries in optimal range.

Nearly all sealed batteries can be mounted on the side.

Gel batteries are also different on purpose — have a General purpose and deep discharge. Gel battery is better to sustain cyclic charge-discharge. Their use is more desirable in power systems. However, they are more expensive AGM batteries, and especially batteries.

Gel batteries have roughly 10-30% longer service life than AGM batteries. Also, they are less painful to tolerate a deep discharge. One of the main advantages of gel batteries before the AGM is the significant reduction in capacity loss when the temperature of the battery. The disadvantages include the need for strict observance of the charging modes.

Therefore, gel batteries recommended for use where required to ensure a long service life with deeper discharge rates and, if the temperature of the battery drops below 5 degrees Celsius.

AGM batteries are ideal for operation in a buffer mode, as a fallback for the rare power failures. In the case of a too frequent connection to the work of just decreasing their life cycle. In such cases, the use of gel batteries is economically more justified.

System based on technology AGM and GEL have special properties, which are essential for solving problems in the field of Autonomous energy supply.

The batteries, made on technology AGM and GEL, are a lead-acid battery. They have similar numbers of parts. In a robust plastic housing providing the required degree of sealing, placed plate electrodes made of lead or its alloys with other metals. The plate is immersed in acid environment — an electrolyte, which can appear as liquid, or be in a different, more dense and less fluid state. In the result of chemical reactions between the electrodes and the electrolyte produces an electric current. When an external electrical voltage of predetermined magnitude to the terminals of lead plates occur inverse chemical processes, in which the battery restores its original properties, is charged.

There are also special battery technology OPzS that are specifically designed for "heavy" cycle modes.

This type of battery was created specifically for use in power systems. They have low outgassing, allow a lot of cycles of charge/discharge 70% of its nominal capacity without damage and a significant reduction of service life. But this type of battery are not in high demand in Russia due to relatively high cost of the battery compared to GEL and AGM technology.

Basic rules of operation of batteries

1. Do not store battery in a discharged state. In this case, the sulfation of the electrodes. In this case, the battery loses capacity and significantly reduces the battery life.

2. Do not short-circuit battery terminal. This can occur when assembling the battery by unskilled personnel. Strong short-circuit current of a charged battery is able to melt the contacts of the terminals and cause thermal burns. Short circuit also causes serious damage to the battery.

3. Do not attempt to open the housing maintenance-free battery. Contained within the electrolyte can cause a chemical burn.

4. Connect the battery only in accordance with the correct polarity. A fully charged battery has a significant amount of energy and is capable, if improperly connected display device (inverter, controller etc.) down.

5. Don't forget to recycle the old battery in accordance with the regulations for products containing heavy metals and acid.

Source: www.mobipower.ru/

The main types of batteries recommended for use in stand-alone solar power systems: an Integral component of Autonomous solar energy systems are maintenance free batteries with high capacity. Such battery guarantee consistent quality and functional capabilities throughout the entire stated life cycle.

Technology AGM (Absorbent Glass Mat) In the Russian language it can be translated as “absorptive glass”. The electrolyte is also used acid in liquid form. But the space between the electrodes filled with a microporous material separator based on optical fiber. This substance acts like a sponge, it completely sucks all of the acid and keeps it, not allowing to spread.

When a chemical reaction inside a battery are also formed gases (mainly hydrogen and oxygen, their molecules are the constituent parts of water and acid). Their bubbles fill some of the pores, the gas does not escape. He is directly involved in chemical reactions when charging the battery, returning back into the liquid electrolyte. This process is called gas recombination. From the school chemistry course is known that a circular process may not be 100% effective. But in today's AGM batteries, the recombination efficiency reaches 95-99%. Ie inside the case of such a battery is formed negligible amounts of free unwanted gas and the electrolyte does not change its chemical properties for many years. However, after a very long time the free gas inside the battery creates excess pressure, when it reaches a certain level, that triggers a special exhaust valve. This valve also protects the battery from bursting in case of emergency situations: work in extreme conditions, a sharp increase in indoor temperature due to external factors and the like.

The main advantage of AGM batteries to a light GEL is lower the internal resistance of the battery. First of all, it affects the charge time of the battery, which in Autonomous systems is very limited, especially in winter. Thus, the AGM battery is charged faster, which means faster out of the mode of deep discharge, which, obviously, for both types of battery. If the system is Autonomous, that when using the AGM battery, its efficiency will be higher than the same system with battery GEL, because the GEL battery requires more time and power, which may not be enough on cloudy winter days. At low temperatures, gel battery, retains more capacity and is more stable, but as practice shows, in cloudy weather at low charge currents and low temperatures, a gel battery will not charge due to high internal resistance and "stiff" gel electrolyte while AGM battery will be charged by low current charging.

Special maintenance of AGM batteries is not required. Battery manufactured according to AGM technology maintenance-free and extra ventilation. Cheap AGM battery will work well in buffer mode with the depth of discharge of 20%. In this mode serve to 10-15 years.

If their use in a cyclic mode and discharged to at least 30-40%, their lifespan is significantly reduced. The AGM batteries are often used in inexpensive bespereboynik (UPS) and a small stand-alone solar power systems. However, in recent times, there are AGM batteries that are designed for deeper discharges and cyclic modes of operation. Of course, its characteristics are inferior to the GEL battery, but work fine in standalone solar power systems.

But the main technical feature of AGM batteries, unlike standard lead-acid battery, — ability to work in a mode of deep discharge. Ie, they can give electric energy for a long time (hours or even a day) to the point where the energy drops to 20-30% of the initial value. After the charging of such a battery it is almost completely restores its working capacity. Of course, it is completely such a situation can not take place. But the modern AGM batteries can withstand from 600 and above the cycles of deep discharge.

In addition, AGM batteries have very low current self-discharge. A charged battery can be stored unconnected for a long time. For example, over 12 months of inactivity the battery power drops to only 80% of the original. AGM batteries usually have a maximum allowed charge current 0.3 s, and the final charge voltage 15-16V. Such characteristics are achieved not only due to the design features of AGM technology. In the manufacture of batteries used more expensive materials with special properties: electrodes are made from ultra-pure lead, the electrodes do thicker, the electrolyte includes sulfuric acid of high purity.

Technology GEL — ( Gel Electrolite) In liquid electrolyte add material based on silicon dioxide (SiO2), resulting in a thick mass, resembling the consistency of jelly. This mass and filled the space between the electrodes inside the battery. In the process of chemical reactions in the bulk electrolyte there are numerous gas bubbles. These then sinks and encounters of the molecules of hydrogen and oxygen, i.e. gas recombination.

Unlike AGM technology gel batteries better yet recover from deep discharge even when the charging process is not started immediately after charging the battery. They can survive more than 1000 cycles of deep discharge without fundamental loss of its capacity. Since the electrolyte is in a dense condition, it is less susceptible to separation into constituent parts, water and acid, so gel batteries are more resistant to bad parameters of the current float charge.

Perhaps the only disadvantage of the gel technology is the price, it is higher than the AGM batteries of the same capacity. Therefore, use of gel batteries is recommended in complex and expensive systems of Autonomous and reserve electricity. And in cases where disconnection of the external electrical network, with enviable periodicity. Battery GEL better withstand cyclic charge-discharge. Also, they seem to tolerate extreme cold. Reducing capacitance by lowering the temperature of the battery is also smaller than other battery types. More preferably in power systems, when the batteries operate in cyclic modes (charged and discharged every day) and there is no way to maintain the temperature of the batteries in optimal range.

Nearly all sealed batteries can be mounted on the side.

Gel batteries are also different on purpose — have a General purpose and deep discharge. Gel battery is better to sustain cyclic charge-discharge. Their use is more desirable in power systems. However, they are more expensive AGM batteries, and especially batteries.

Gel batteries have roughly 10-30% longer service life than AGM batteries. Also, they are less painful to tolerate a deep discharge. One of the main advantages of gel batteries before the AGM is the significant reduction in capacity loss when the temperature of the battery. The disadvantages include the need for strict observance of the charging modes.

Therefore, gel batteries recommended for use where required to ensure a long service life with deeper discharge rates and, if the temperature of the battery drops below 5 degrees Celsius.

AGM batteries are ideal for operation in a buffer mode, as a fallback for the rare power failures. In the case of a too frequent connection to the work of just decreasing their life cycle. In such cases, the use of gel batteries is economically more justified.

System based on technology AGM and GEL have special properties, which are essential for solving problems in the field of Autonomous energy supply.

The batteries, made on technology AGM and GEL, are a lead-acid battery. They have similar numbers of parts. In a robust plastic housing providing the required degree of sealing, placed plate electrodes made of lead or its alloys with other metals. The plate is immersed in acid environment — an electrolyte, which can appear as liquid, or be in a different, more dense and less fluid state. In the result of chemical reactions between the electrodes and the electrolyte produces an electric current. When an external electrical voltage of predetermined magnitude to the terminals of lead plates occur inverse chemical processes, in which the battery restores its original properties, is charged.

There are also special battery technology OPzS that are specifically designed for "heavy" cycle modes.

This type of battery was created specifically for use in power systems. They have low outgassing, allow a lot of cycles of charge/discharge 70% of its nominal capacity without damage and a significant reduction of service life. But this type of battery are not in high demand in Russia due to relatively high cost of the battery compared to GEL and AGM technology.

Basic rules of operation of batteries

1. Do not store battery in a discharged state. In this case, the sulfation of the electrodes. In this case, the battery loses capacity and significantly reduces the battery life.

2. Do not short-circuit battery terminal. This can occur when assembling the battery by unskilled personnel. Strong short-circuit current of a charged battery is able to melt the contacts of the terminals and cause thermal burns. Short circuit also causes serious damage to the battery.

3. Do not attempt to open the housing maintenance-free battery. Contained within the electrolyte can cause a chemical burn.

4. Connect the battery only in accordance with the correct polarity. A fully charged battery has a significant amount of energy and is capable, if improperly connected display device (inverter, controller etc.) down.

5. Don't forget to recycle the old battery in accordance with the regulations for products containing heavy metals and acid.

Source: www.mobipower.ru/