666

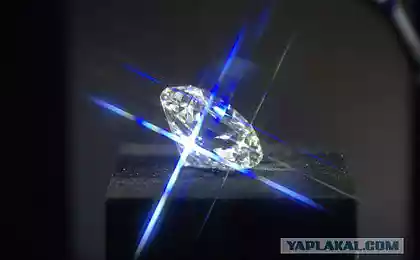

Girl's best friend. As facets of a diamond.

Not known steamers uniform "Zvezdochka". Since the early 2000s the company started production of diamond cutting diamonds. As many probably know, diamond, for all its other merits of a technical nature only becomes «the girl's best friend», when transformed into a diamond. On what way it will go while our present photo story.

It begins with a hanger ... guess. The visitors to break post production processing of solid materials (as officially called the cut), offer to put on a dressing gown, hand over hand luggage, sew pockets and attach at least two attendants: shop worker performing the role of a guide and an employee of economic security. Trust, as they say, but verify.

Now we're ready to get acquainted with the department. The first item on the itinerary - pantry raw materials.

44 pics + text.

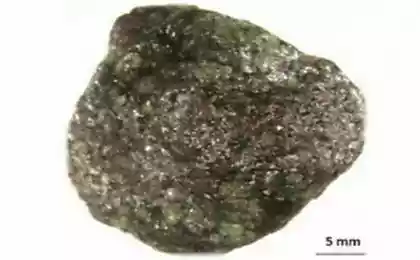

It is here comes the raw material - rough diamonds. Here they will be received: Recalculate weigh, verify that the shipping documents, ENTERED every stone in an electronic database of records and discharged on each stone kind of road map. In this roadmap, folded in an envelope, diamond and will travel sites.

From the pantry diamond falls on UZTTS - section closed technological cycle. Here technologists will sort and mark stones.

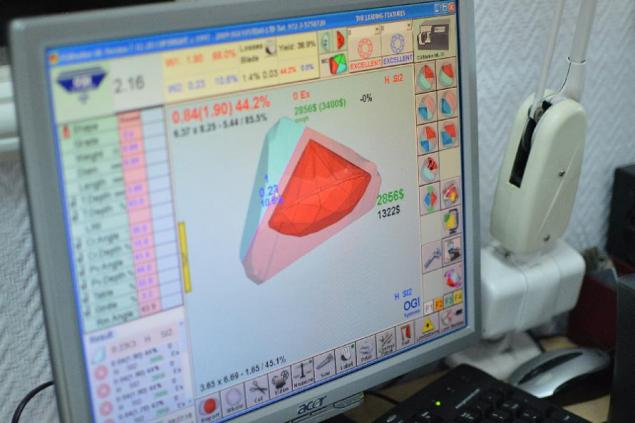

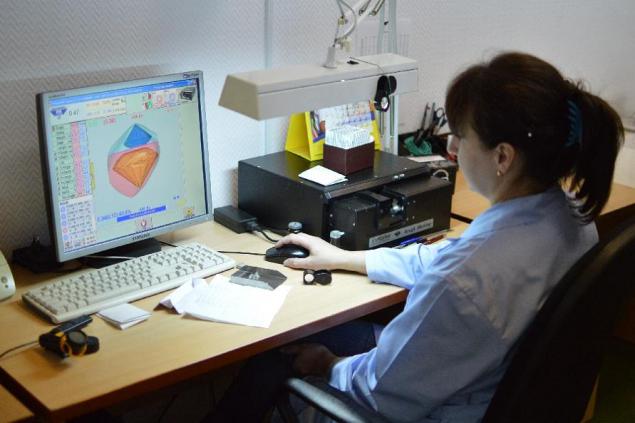

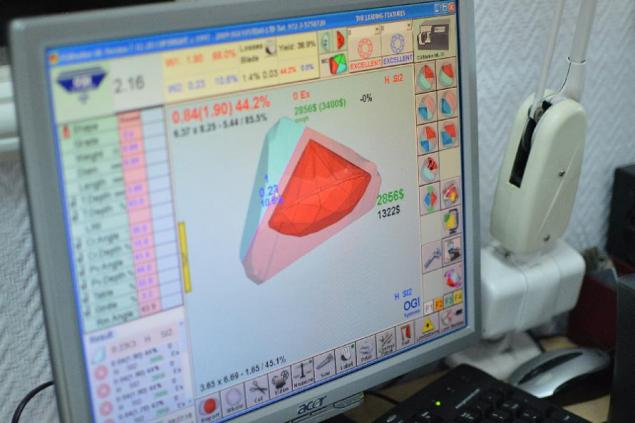

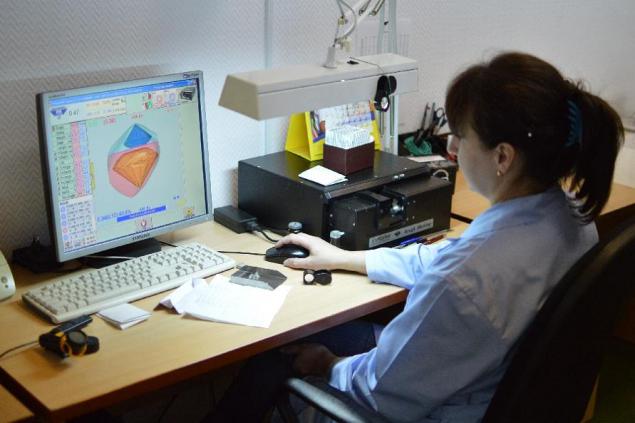

This is done by means of a computer system layout. Installing scans diamond and creates a three-dimensional digital model. Using this model technologist will decide how many diamonds come from a particular stone and what form they will have. The cornerstone put the principle of combining the cost of future diamond and waste minimization. The program not only allows you to visualize the hidden diamonds in diamond, but also give them the approximate cost. The classical form of cut KR-57 typically has a maximum value. Unfortunately, not every natural stone allows for precisely this form with maximum use of raw materials.

The cost of this diamond placers 3560 dollars.

From this stone will one diamond, but little more. The cost will be a little less than three thousand dollars.

And because of this - two, but smaller and, consequently, a more modest pocket.

Before you leave the site, the stones are glued to the special mandrel for subsequent processing. This small stands heated in an oven to glue reliably picked diamonds.

With UZTTS stones fall on site cutting and stripping. In the old days sawing stone was carried out mechanically by a bronze disc with diamond-coated.

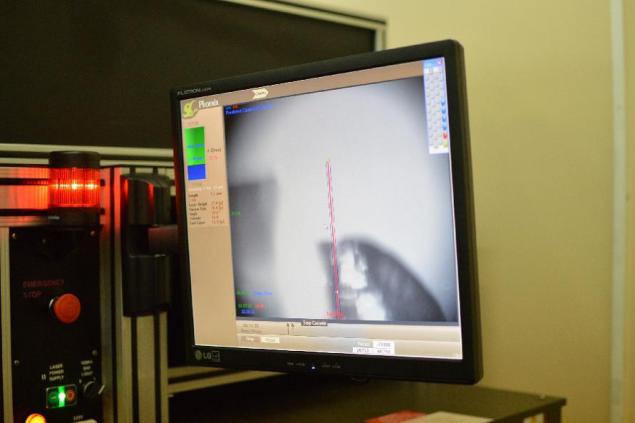

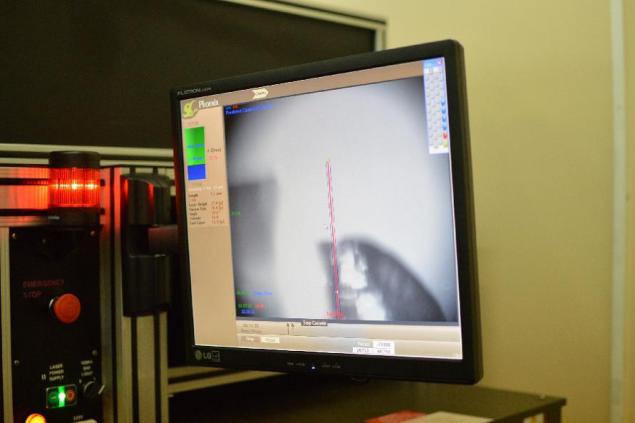

Today, the bulk of the cutting is carried out by laser. The plant operator has the ability to visually monitor the process.

Laser cutting, firstly, the faster. Process according to sawing stone sizes can range from five minutes to an hour. Secondly, the thickness of the laser cutting is only 2 microns, which significantly saves rough.

However, some of the stones having a high internal stress, laser cutting dangerous. And then sawing held in the old - a bronze disc.

Source:

It begins with a hanger ... guess. The visitors to break post production processing of solid materials (as officially called the cut), offer to put on a dressing gown, hand over hand luggage, sew pockets and attach at least two attendants: shop worker performing the role of a guide and an employee of economic security. Trust, as they say, but verify.

Now we're ready to get acquainted with the department. The first item on the itinerary - pantry raw materials.

44 pics + text.

It is here comes the raw material - rough diamonds. Here they will be received: Recalculate weigh, verify that the shipping documents, ENTERED every stone in an electronic database of records and discharged on each stone kind of road map. In this roadmap, folded in an envelope, diamond and will travel sites.

From the pantry diamond falls on UZTTS - section closed technological cycle. Here technologists will sort and mark stones.

This is done by means of a computer system layout. Installing scans diamond and creates a three-dimensional digital model. Using this model technologist will decide how many diamonds come from a particular stone and what form they will have. The cornerstone put the principle of combining the cost of future diamond and waste minimization. The program not only allows you to visualize the hidden diamonds in diamond, but also give them the approximate cost. The classical form of cut KR-57 typically has a maximum value. Unfortunately, not every natural stone allows for precisely this form with maximum use of raw materials.

The cost of this diamond placers 3560 dollars.

From this stone will one diamond, but little more. The cost will be a little less than three thousand dollars.

And because of this - two, but smaller and, consequently, a more modest pocket.

Before you leave the site, the stones are glued to the special mandrel for subsequent processing. This small stands heated in an oven to glue reliably picked diamonds.

With UZTTS stones fall on site cutting and stripping. In the old days sawing stone was carried out mechanically by a bronze disc with diamond-coated.

Today, the bulk of the cutting is carried out by laser. The plant operator has the ability to visually monitor the process.

Laser cutting, firstly, the faster. Process according to sawing stone sizes can range from five minutes to an hour. Secondly, the thickness of the laser cutting is only 2 microns, which significantly saves rough.

However, some of the stones having a high internal stress, laser cutting dangerous. And then sawing held in the old - a bronze disc.

Source: