Heat recovery from commercial refrigeration equipment.

Bashny.Net

Bashny.Net

Many companies are looking for ways to reduce the consumed amount of electricity and the high cost of energy makes this finding a way to survive in the market. In this commercial refrigeration equipment for Central or remote refrigeration systems in supermarkets allocates a sufficiently large amount of heat, due to which there are opportunities for energy saving.

It is no secret that one of the significant costs of a large grocery store is a fee for the electricity consumption for refrigeration and other commercial equipment.

Many companies today are looking for ways to minimize the consumed amount of electricity and the high cost of energy, which is constantly moving upward, making the search for a way to survive in the market. At the same refrigeration facility for Central or remote refrigeration systems in supermarkets allocate a sufficiently large amount of heat that the condensation process of the refrigerant is most often disposed into the environment. It is due to this heat there is the potential for energy conservation in industry and trade.

The West has long and universally used system recover heat of refrigeration installations. In the domestic market in recent years has also been an increase of interest in this kind of systems. The heat recovery system is relevant to the objects on which simultaneously with the need for refrigeration there is a need for hot water or heating. Such an object could be a supermarket or hypermarket.

The growth of energy prices, desire to reduce operating costs and environmental safety lead to an increase in the use of various energy saving systems in refrigeration and air conditioning systems. To reduce energy consumption during operation of the refrigeration equipment in today's supermarkets, along with the use of less energy-intensive commercial refrigeration equipment, and special automation components and electronic control systems becoming more widespread find heat recovery systems. The temperature of the injected refrigerant vapor in refrigerant circuits is quite high, which leads to the formation of large amounts of heat, which is most often vented to the atmosphere. The use of heat recovery systems allows you to use this heat for heating of various fluids (air, water, etc.)

Refrigeration equipment store generates quite a large amount of heat, which is heat abstracted from the refrigerated volume and heat, attached in the compression process of refrigerant or compressor unit. Most often this heat is discharged into the atmosphere. Heat recovery system allows the use of this heat for water heating from +10 to +60 °C, using about 20 % of the heat generated by the refrigeration equipment. The load on the refrigerating machine shops over the year remains nearly constant. For the low temperature system load fluctuations amount to about 10 %, and for medium temperature — about 20-25 %. Thus, in some cases, the heat recovery system allows to completely abandon the hot water at the facility.

RECOVERY TECHNOLOGY

The essence of recovery is the capture and efficient use of the heat that is normally discharged to the condenser of the refrigeration unit into the atmosphere, the heat may be directed to heated gas (the atmosphere space), liquids and solids. Any user of the cold should understand that the energy that is discharged into the atmosphere by the condenser, can be used. This can be a heated space located in the vicinity of refrigeration, heating process water, heating various kinds of fluids, the use of heat in technological processes. A number of limitations associated primarily with low potentiality of this energy, it is possible to avoid using the most modern and efficient heat transfer equipment and automation, as well as innovative solutions.

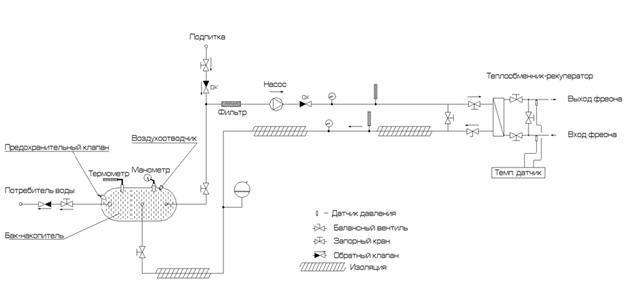

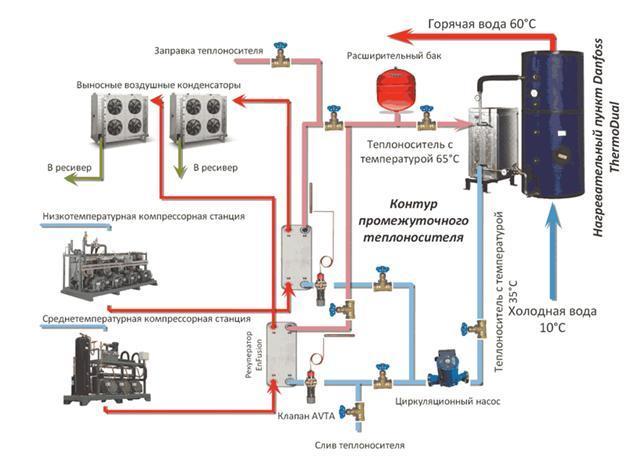

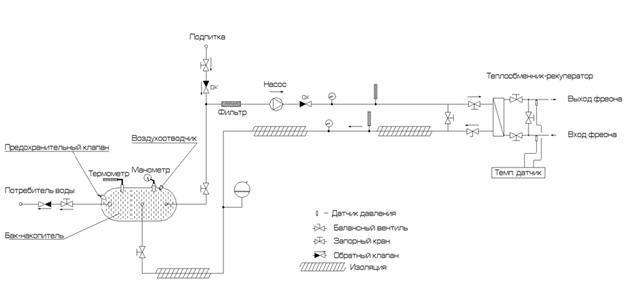

The heat recovery system is translating it into spoken language, return heat back.In cooling systems formed a certain amount of heat in the compression process by the compressor refrigerant vapor coming from the evaporation system. In the future, this heated and compressed vapor piping enters the condenser where it is cooled and liquefied. And here on this site and installed additional heat exchanger in which hot refrigerant vapor, and on the other to counter it — the coolant (water, ethylene glycol, propylene glycol). In the heat exchanger occurs the heat transfer from the steam to the coolant and the accumulation of this heat in the tank drive. From storage tank the heat transfer fluid can be spent on various household needs. The temperature of the media can make any, changing the choice of the heat exchanger its characteristics, typically achieve a temperature of +50...+60 °C(scheme 1)

In most cases, the coolant used:

— to preheat cold water going to the sanitary and economic needs;

— for heating of water in systems of heating and ventilation;

— at the ice arena for snow melting;

— in supply and exhaust ventilation;

in any heating system.

As an example, consider the use of heat overheating allocated CHM, for the organization of domestic hot water (DHW) in the supermarket with a sales area of 1200 m2, Glatonbury on the object by two or compressor cooling units. The heat recovery system consists of two (for medium and low temperature circuits) shell and tube heat exchangers with centrifugal pumps and insulation of the storage tank (water heater). Cold water with temperature about +10°C of the water enters the storage tank, where with the help of the circulation pumps is supplied to the heat exchangers, where by pressurizing refrigerant vapor is heated up to +55...+60°C, and then distributed to consumers.

Refrigeration walk-in cooler installation — 94 kW at the boiling point -10°C, low temperature — 26 kW at the boiling point of -35°C and condensation temperature +40°C. the Heat of overheating allocated to a working station, respectively and 13.8 to 31.4 kW. The total heat that can be used to heat water, 45,2 kW. As a result of calculations we get that the total volume of water that can be heated in the heat exchangers from +10 to +55°C, equal to 0.24 kg/s considering the coefficient of working time, the frequency and duration of defrost periods and so on — we get about 600 l/h, which will provide the supermarket with a sales area of 1200 m2 hot water for technical needs.

In the case of use for obtaining the same amount of hot water water heating elements of the annual electricity demand will be 274363,2 kWh. while a fairly simple analysis shows that the immaterial costs of additional equipment at the initial stage will allow further economic benefit from the heat produced by existing equipment, and not to throw it into the environment. The heat recovery system is easy to install and operate, and the only necessary condition is the existence of a Central system of cold water supply. And the payback period will not exceed 1.5 years.

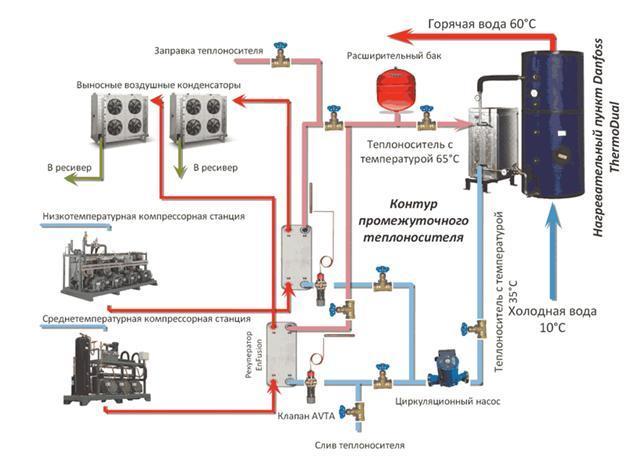

Our company installs the system recovery. The heat recovery system consists of a heat exchanger or several heat exchangers connected in parallel, and the substation. Part of the substation includes the storage tank, gasketed plate heat exchanger, your circulator, balancing valve, valve emergency pressure relief, thermometer. The heat exchanger is installed in the discharge line of the refrigeration unit and provides heating of the intermediate coolant (water) from +35 to +65°C. Circuit intermediate coolant connected to the heat exchanger, which is part of substation, which in turn provides water heating from +10 to +60°C for the needs of DHW.

Each heat exchanger is equipped with a thermostatic valve AVTA or WVTS, which maintains a constant temperature intermediate coolant when you change the performance of the refrigeration unit, ensuring, thus, the temperature of the water at the outlet of the recovery system +60°C.

Accessories a heat recovery system, it is preferable to implement based on the needs of a particular object. In this case, the capital cost components will be minimal and the payback period of recovery systems will be from six months to two years.

Cost recovery systems at the moment are quite high, If you compare the price of the boiler with electric heating and similar device that heats water hot vapors of the refrigerant, the conventional electric heater will be cheaper in 3-4 times, but he will regularly consume is not free electricity. And assuming that the object is a shortage of electricity? We immediately received a lot of positive emotions from recovery systems: energy savings, hot water without the cost of Parking, reducing the electrical load. Generally, recuperation pay off in 1-2 years (only energy saving) and has a lifetime of 7-10 years.

Our engineers have extensive experience in the design of such systems, and the installers have often collected them. Only an individual approach and high professionalism will make recovery systems available and truly effective.

water heating.

In modern shopping centers and supermarkets, where a large number of features and points of public catering and system of ventilation and conditioning, use of heat recovery systems can be justified, if the facility has its own boiler room with the possibility of preparing hot water for all of the above consumer Direct savings on the energy source for the boiler will be obvious

.

The decision on the use of recovery is in every case individual character, but in any case it brings only positive emotions to make the decision.

P. S. And remember, only by changing their consumption — together we change the world! ©

Join us in Facebook , Vkontakte, Odnoklassniki

Source: install-energy.com.ua/rekuperatsiya-tepla-ot-torgovogo-kholodilnogo-oborudovaniya/

It is no secret that one of the significant costs of a large grocery store is a fee for the electricity consumption for refrigeration and other commercial equipment.

Many companies today are looking for ways to minimize the consumed amount of electricity and the high cost of energy, which is constantly moving upward, making the search for a way to survive in the market. At the same refrigeration facility for Central or remote refrigeration systems in supermarkets allocate a sufficiently large amount of heat that the condensation process of the refrigerant is most often disposed into the environment. It is due to this heat there is the potential for energy conservation in industry and trade.

The West has long and universally used system recover heat of refrigeration installations. In the domestic market in recent years has also been an increase of interest in this kind of systems. The heat recovery system is relevant to the objects on which simultaneously with the need for refrigeration there is a need for hot water or heating. Such an object could be a supermarket or hypermarket.

The growth of energy prices, desire to reduce operating costs and environmental safety lead to an increase in the use of various energy saving systems in refrigeration and air conditioning systems. To reduce energy consumption during operation of the refrigeration equipment in today's supermarkets, along with the use of less energy-intensive commercial refrigeration equipment, and special automation components and electronic control systems becoming more widespread find heat recovery systems. The temperature of the injected refrigerant vapor in refrigerant circuits is quite high, which leads to the formation of large amounts of heat, which is most often vented to the atmosphere. The use of heat recovery systems allows you to use this heat for heating of various fluids (air, water, etc.)

Refrigeration equipment store generates quite a large amount of heat, which is heat abstracted from the refrigerated volume and heat, attached in the compression process of refrigerant or compressor unit. Most often this heat is discharged into the atmosphere. Heat recovery system allows the use of this heat for water heating from +10 to +60 °C, using about 20 % of the heat generated by the refrigeration equipment. The load on the refrigerating machine shops over the year remains nearly constant. For the low temperature system load fluctuations amount to about 10 %, and for medium temperature — about 20-25 %. Thus, in some cases, the heat recovery system allows to completely abandon the hot water at the facility.

RECOVERY TECHNOLOGY

The essence of recovery is the capture and efficient use of the heat that is normally discharged to the condenser of the refrigeration unit into the atmosphere, the heat may be directed to heated gas (the atmosphere space), liquids and solids. Any user of the cold should understand that the energy that is discharged into the atmosphere by the condenser, can be used. This can be a heated space located in the vicinity of refrigeration, heating process water, heating various kinds of fluids, the use of heat in technological processes. A number of limitations associated primarily with low potentiality of this energy, it is possible to avoid using the most modern and efficient heat transfer equipment and automation, as well as innovative solutions.

The heat recovery system is translating it into spoken language, return heat back.In cooling systems formed a certain amount of heat in the compression process by the compressor refrigerant vapor coming from the evaporation system. In the future, this heated and compressed vapor piping enters the condenser where it is cooled and liquefied. And here on this site and installed additional heat exchanger in which hot refrigerant vapor, and on the other to counter it — the coolant (water, ethylene glycol, propylene glycol). In the heat exchanger occurs the heat transfer from the steam to the coolant and the accumulation of this heat in the tank drive. From storage tank the heat transfer fluid can be spent on various household needs. The temperature of the media can make any, changing the choice of the heat exchanger its characteristics, typically achieve a temperature of +50...+60 °C(scheme 1)

In most cases, the coolant used:

— to preheat cold water going to the sanitary and economic needs;

— for heating of water in systems of heating and ventilation;

— at the ice arena for snow melting;

— in supply and exhaust ventilation;

in any heating system.

As an example, consider the use of heat overheating allocated CHM, for the organization of domestic hot water (DHW) in the supermarket with a sales area of 1200 m2, Glatonbury on the object by two or compressor cooling units. The heat recovery system consists of two (for medium and low temperature circuits) shell and tube heat exchangers with centrifugal pumps and insulation of the storage tank (water heater). Cold water with temperature about +10°C of the water enters the storage tank, where with the help of the circulation pumps is supplied to the heat exchangers, where by pressurizing refrigerant vapor is heated up to +55...+60°C, and then distributed to consumers.

Refrigeration walk-in cooler installation — 94 kW at the boiling point -10°C, low temperature — 26 kW at the boiling point of -35°C and condensation temperature +40°C. the Heat of overheating allocated to a working station, respectively and 13.8 to 31.4 kW. The total heat that can be used to heat water, 45,2 kW. As a result of calculations we get that the total volume of water that can be heated in the heat exchangers from +10 to +55°C, equal to 0.24 kg/s considering the coefficient of working time, the frequency and duration of defrost periods and so on — we get about 600 l/h, which will provide the supermarket with a sales area of 1200 m2 hot water for technical needs.

In the case of use for obtaining the same amount of hot water water heating elements of the annual electricity demand will be 274363,2 kWh. while a fairly simple analysis shows that the immaterial costs of additional equipment at the initial stage will allow further economic benefit from the heat produced by existing equipment, and not to throw it into the environment. The heat recovery system is easy to install and operate, and the only necessary condition is the existence of a Central system of cold water supply. And the payback period will not exceed 1.5 years.

Our company installs the system recovery. The heat recovery system consists of a heat exchanger or several heat exchangers connected in parallel, and the substation. Part of the substation includes the storage tank, gasketed plate heat exchanger, your circulator, balancing valve, valve emergency pressure relief, thermometer. The heat exchanger is installed in the discharge line of the refrigeration unit and provides heating of the intermediate coolant (water) from +35 to +65°C. Circuit intermediate coolant connected to the heat exchanger, which is part of substation, which in turn provides water heating from +10 to +60°C for the needs of DHW.

Each heat exchanger is equipped with a thermostatic valve AVTA or WVTS, which maintains a constant temperature intermediate coolant when you change the performance of the refrigeration unit, ensuring, thus, the temperature of the water at the outlet of the recovery system +60°C.

Accessories a heat recovery system, it is preferable to implement based on the needs of a particular object. In this case, the capital cost components will be minimal and the payback period of recovery systems will be from six months to two years.

Cost recovery systems at the moment are quite high, If you compare the price of the boiler with electric heating and similar device that heats water hot vapors of the refrigerant, the conventional electric heater will be cheaper in 3-4 times, but he will regularly consume is not free electricity. And assuming that the object is a shortage of electricity? We immediately received a lot of positive emotions from recovery systems: energy savings, hot water without the cost of Parking, reducing the electrical load. Generally, recuperation pay off in 1-2 years (only energy saving) and has a lifetime of 7-10 years.

Our engineers have extensive experience in the design of such systems, and the installers have often collected them. Only an individual approach and high professionalism will make recovery systems available and truly effective.

water heating.

In modern shopping centers and supermarkets, where a large number of features and points of public catering and system of ventilation and conditioning, use of heat recovery systems can be justified, if the facility has its own boiler room with the possibility of preparing hot water for all of the above consumer Direct savings on the energy source for the boiler will be obvious

.

The decision on the use of recovery is in every case individual character, but in any case it brings only positive emotions to make the decision.

P. S. And remember, only by changing their consumption — together we change the world! ©

Join us in Facebook , Vkontakte, Odnoklassniki

Source: install-energy.com.ua/rekuperatsiya-tepla-ot-torgovogo-kholodilnogo-oborudovaniya/

Tags

See also

Single mini choppers

Skylock - wireless bicycle lock Solar

The use of hybrid drives in construction machinery

German company offers to heat use servers for heating apartments

Alternative energy for the home with their hands: a review of the best eco-technologies

Brands that have become a household name

The heart of the empire Google

Excursion to the biggest fridge in Ukraine.

History of Samsung Electronics: From dried fish to high-tech

Why Russia is almost no civil / commercial high-tech manufacturing?