526

Australian university student has saved his lab about $ 5,000, for printing details microscope

Freshman designed and manufactured camera for immersion microscopes Laboratory University

History of optical microscopy has about 4 centuries. It really is a very long way, during all this time there were different models of microscopes, very different design. lighting systems, lenses, enclosures microscopes of different models from different time intervals differ dramatically. At the moment, one of the best ways to "squeeze" all of the optical microscope is an immersion system. It is often used in an increase of about 1000 times. And for perfect results use an immersion system, consisting of the immersion lens and oil. Oil fill the gap between the studied object and the front lens of the immersion objective. Such a process helps to avoid the loss of light rays, while creating an optimal illumination of the field of view.

At the University of New South Wales used just immersion microscopes. In such a system uses a special camera, in which there is oil. Moreover, the cost of the camera is very rather big - about $ 400. These cameras have to be replaced sometimes, which results in significant costs. Even for the University, which gets a good financing, replacement of several immersion cameras at once - a difficult task. Home university decided to help the student Gudnou Ben (Ben Goodnow), who undertook the production of the camera yourself.

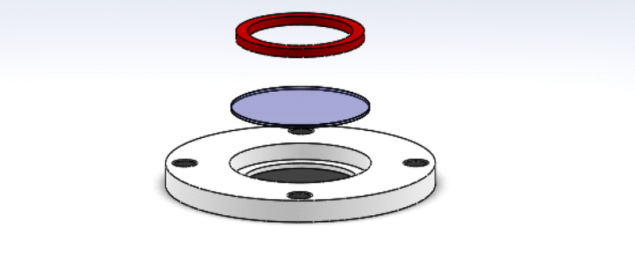

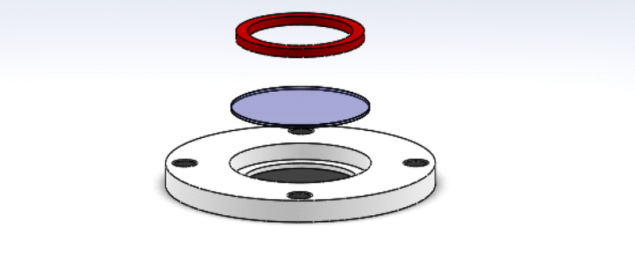

Freshman used his experience with 3D printing and laser cutting, and made compatible with the microscope camera. The cost of its manufacture is much lower than the cost of the original camera. According to the calculations of the student, making the camera costs about $ 20 (with the use of third-party services, commissioned the printing parts and laser cutting involved). Camera model (CAD files for special programs) posted on GitHub, there is a detailed description of the entire process of manufacturing cameras.

The main part of the chamber created from ABC plastic, using a laser cut silicone gaskets. Rare-earth magnets (Neodymium) hold the entire structure.

Student has calculated that a single cell can be produced for about $ 103.5 (four times cheaper than buying ready-made). But the more typical elements do, the cheaper it all costs. With third-party materials and services payment received about $ 63.5 for all ten made cameras. Separate production of immersion cameras resulted in savings of about $ 5,000 for your university.

Source: geektimes.ru/post/274382/

History of optical microscopy has about 4 centuries. It really is a very long way, during all this time there were different models of microscopes, very different design. lighting systems, lenses, enclosures microscopes of different models from different time intervals differ dramatically. At the moment, one of the best ways to "squeeze" all of the optical microscope is an immersion system. It is often used in an increase of about 1000 times. And for perfect results use an immersion system, consisting of the immersion lens and oil. Oil fill the gap between the studied object and the front lens of the immersion objective. Such a process helps to avoid the loss of light rays, while creating an optimal illumination of the field of view.

At the University of New South Wales used just immersion microscopes. In such a system uses a special camera, in which there is oil. Moreover, the cost of the camera is very rather big - about $ 400. These cameras have to be replaced sometimes, which results in significant costs. Even for the University, which gets a good financing, replacement of several immersion cameras at once - a difficult task. Home university decided to help the student Gudnou Ben (Ben Goodnow), who undertook the production of the camera yourself.

Freshman used his experience with 3D printing and laser cutting, and made compatible with the microscope camera. The cost of its manufacture is much lower than the cost of the original camera. According to the calculations of the student, making the camera costs about $ 20 (with the use of third-party services, commissioned the printing parts and laser cutting involved). Camera model (CAD files for special programs) posted on GitHub, there is a detailed description of the entire process of manufacturing cameras.

The main part of the chamber created from ABC plastic, using a laser cut silicone gaskets. Rare-earth magnets (Neodymium) hold the entire structure.

Student has calculated that a single cell can be produced for about $ 103.5 (four times cheaper than buying ready-made). But the more typical elements do, the cheaper it all costs. With third-party materials and services payment received about $ 63.5 for all ten made cameras. Separate production of immersion cameras resulted in savings of about $ 5,000 for your university.

Source: geektimes.ru/post/274382/

The first shots of the film adaptation of the cult cyberpunk anime «Ghost in the Shell» caused a mixed reaction of fans

In what conditions financiers work: Excursion to Goldman Sachs Offices and Bloomberg