726

Developed nanofibers gives the material color without using paint

Chinese researchers from the University of Soochow (Suzhou District in Jiangsu Province) under the leadership of physicist and chemist of polymers Re-Quinn Zhang смогли thus produce nanofibers latex , that they were the property of "structural color". By adjusting the length of the fibers, scientists have made the transmission of different colors. If they manage to make these fibers of sufficient strength, in the future it will be possible to produce multi-colored fabric without the use of dyes.

Dyeing fabrics in modern light industry requires a large amount of pigment. Depending on the color, pigment can be quite expensive . In the painting spent a lot of water and energy, and waste and discarded things can pollute the environment.

Effect structural color , or "skhemohroma" gives visible color surfaces that have no real pigment. Because of the microscopic structure of the surface features of the light reflected from them is subject to interference, so that changes color. So enjoy the effect in nature peacocks, some birds, butterflies and beetles, as well as the recently discovered scientists - partly chameleons .

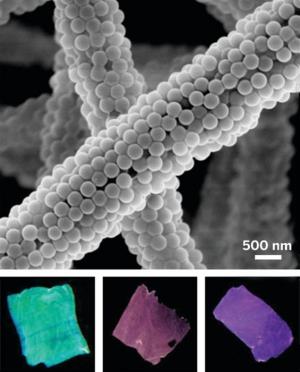

This same effect, and I wanted to use the Re-Quinn Zhang to create fibers. They colleagues began to synthesize nanoparticles of the same size of the synthetic latex on the basis of polystyrene (P (St-MMA-AA)). The resulting nanospheres of this material scientists injected a solution of (ПВС), and the resulting viscous liquid was taken by syringe.

Then use the « elektropryazhi », a process in which an electric charge pulls nano-sized fibers from a liquid, the scientists created a small mats they then wash and dried. Laundry washed away the remnants of PVA, and the eyes of scientists brought colorful mats consisting of fibers tightly packed nanospheres.

Color mat depends on the size of nanospheres. Their size is related to the wavelength of light, so a set of identical spheres reflects only light with a specific wavelength, giving almost pure color. Areas of 220 nm green fiber yield, 246 nm - red, 280 nm - purple.

However, the real color is received net of Mie scattering - рассеяния light spherical particle (after the German physicist Gustav Mie, who solved this problem in 1908). If the nanofiber packed in flat glass tubes, they form a regular geometric structure and reduced parasitic scattering.

But the main problem is still the mechanical resistance - The thus obtained fiber diameter of 1.3 microns are not strong enough in order to use them in the clothing. When the scientists will be able to create a sufficient fiber strength, fiber will undoubtedly find their application in various fields of industry.

Source: geektimes.ru/post/252634/