2645

Brake Airbus-320

Again, the air materiel.

Today we look Jets brake.

Brakes different planes are very similar to each other and to the parts of the structure are slightly different - basically a method of attaching to the axis.

We will study the brake by Airbus-320.

The brake can be supplied in various transport package; for example, here in this.

24 photo.

Weighs such a thing about 100kg, of which approximately 70 kg - the brake itself.

Here it is in all its glory:

As can be seen, brakes - disc.

Specifically, this model contains four mobile and fixed five discs.

Discs - carboxylic and are lined with a metal slot for connection with the splines of the wheel.

Before installing the wheels aligned wheels and wheel their slots fits into these grooves.

On the inside of the wheel can be seen shining heat shield.

When braking, the brakes of the aircraft can be heated to 300 degrees or more, and the screen helps to lower heating disc wheels and tires.

Cooled brake through the holes in the rim or naturally:

Or can be mounted on the wheel cover with a fan for forced cooling:

Axial fan driven by an electric motor inside the axis sucks air from outside

and drives it through the holes in the wheels on, through the brake discs towards amortstoyki.

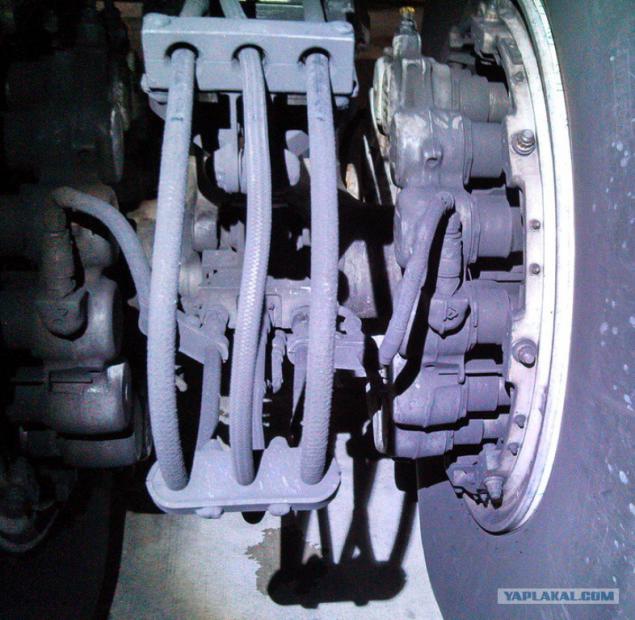

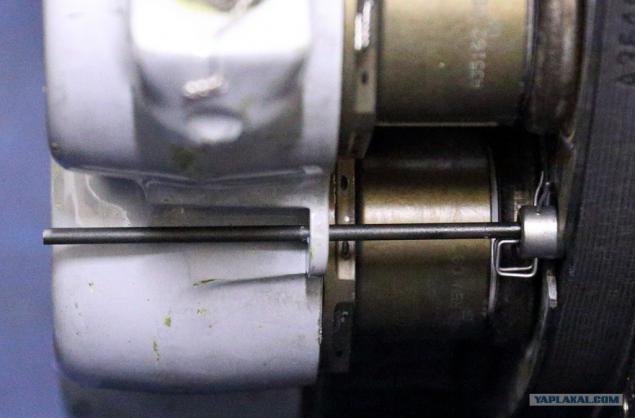

The hydraulic part of the brake cylinders provided housing.

Hydraulic cylinders then 14 - seven on the primary and secondary braking system, located in one.

Here it is clearly seen that the systems do not work simultaneously

(One piston is not involved, the other pushes the wheels)

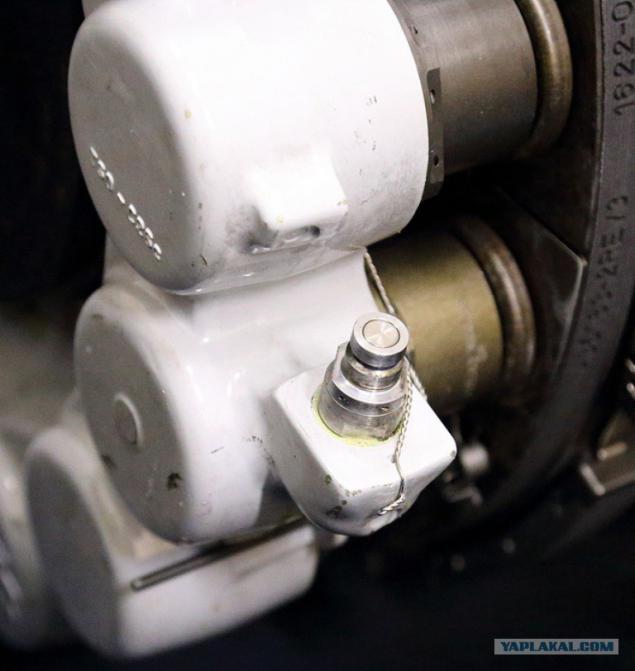

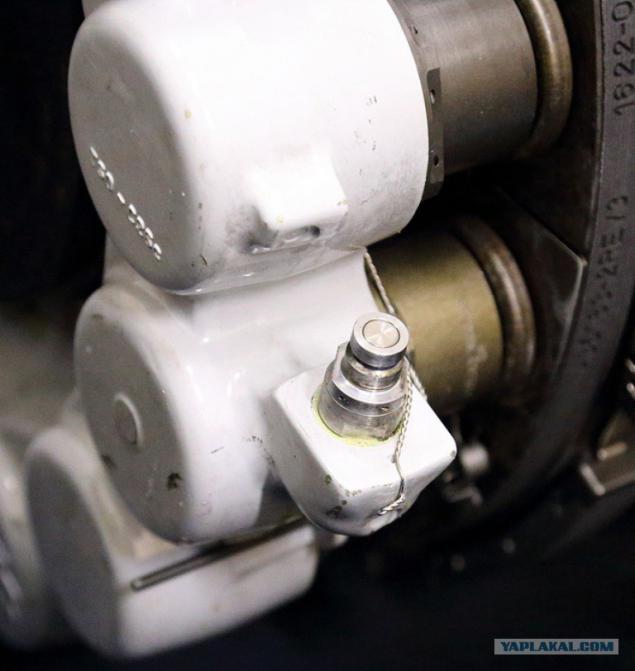

The upper cylinders are fittings for venting air pockets after installing brake:

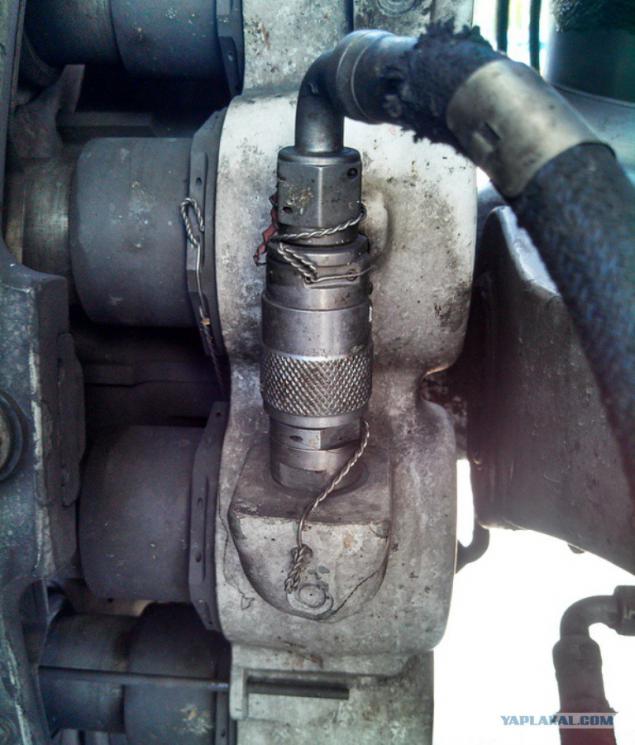

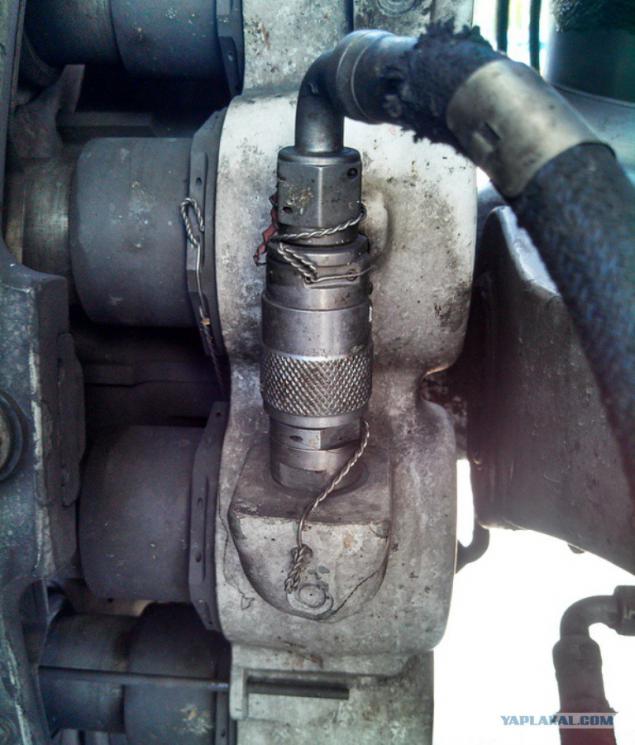

Hydraulic fluid to the collectors and the main alternative systems supplied by Connectors:

It is, without exaggeration, the great, the invention makes it possible to disconnect the hydraulic hoses for a couple of seconds.

It does not Contra and just need to turn the hose connector, to withdraw from the engagement to pin on the brake, and remove.

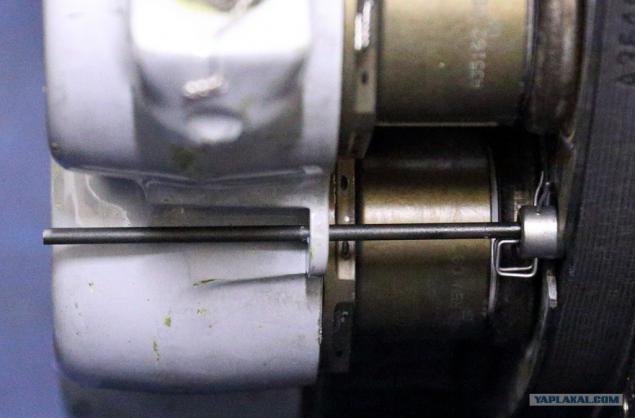

The brake wear indicator has two discs - front and back.

These pins (pins) attached sticking out of the slot in the housing.

When the brake is worn down to the need to replace, the protrusion of the pins for the plane body will be zero:

Naturally, it is necessary to check the wear on compressed disks. This is usually done with the parking brake on.

Pina there are different because different manufacturers sfotkatsya brakes.

After removal of the brake wear it is sent to the bulkhead. There, his clean, controlled and set new wheels.

Downstairs has a brake temperature sensor:

Fasten the brakes on different planes differently.

737 Classic brake bolted. It seems the 12th. Each bolt had to be tightened in two stages - first pull one point of bolts (not nuts) diagonally, and then - big moments in a circle. That more fun :)

At 737 NG brake at all luxurious. He was not screwed anything :) - Keep only by pressing the wheel, and the moment takes a hefty rectangular bar sticking out of amortstoyki. Brake when replacing a worn it.

A brake on the A320 is at an intermediate stage of evolution :) - he screwed all three nuts.

A moment from braking is transmitted to the rack through the three bolts, plus nine pins that are simply put on the brake when you install.

Here are the pictures just seen the bottom two nuts and among one of the nine pins.

The upper fixing nut (arrow)

inconveniently located, just opposite the stem amortstoyki.

Therefore, to replace the brakes need to have a torque wrench with an extension cord and head falling exactly into the small space between the counter and the brake housing :)

And in the end, as usual, to scare you ugly :)

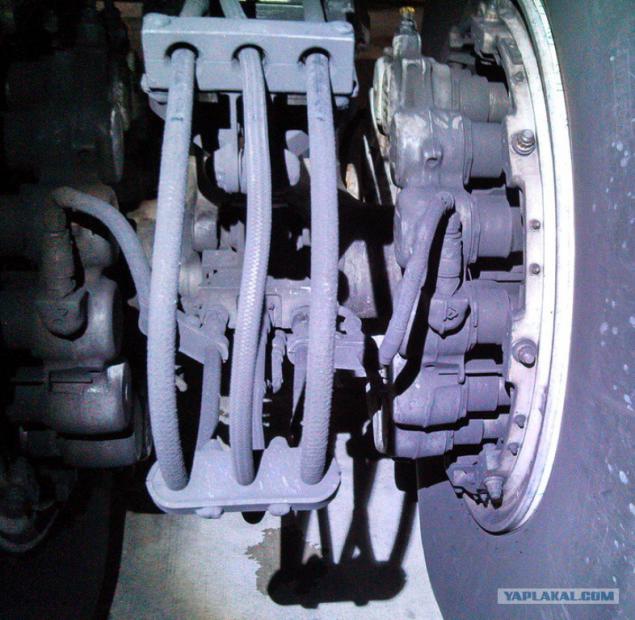

Here is the lower part of the back amortstoyki:

We observe in the foreground two hydraulic hose on each side - the left and right brakes;

between them - a cable with wires of the temperature measuring system of brakes, power fans and sensors tachometer wheel (also located inside the axis of the rack).

I would like to respond immediately and prevent issues.

Why is all that dirty.

Ladies.

Sorry, blah.

Such is life.

The chassis is always very dirty.

This fine dust from wear carboxylic drives all flying here.

The plane slows down its 60 tons from 230 km / h to zero in a minute - what do you want?

Sticks and just dust.

Plus here blows grease. And sometimes a little hydraulic oil.

The only touch of this Heri immediately stain your hands for a few days. Their otmoesh FIG.

So - on all planes. Any companies.

I understand that I break your dreams of a white liner, but if you want to know how the materiel in fact - it's so she arranged.

There glamorous interior that fag gang cleaners after each arrival, and there is the chassis.

And then there are the fuselage, sometimes with streaks of hydraulic fluid and lubrication lyapami.

The world is.

Those who did not die from the truth of life, complete training.

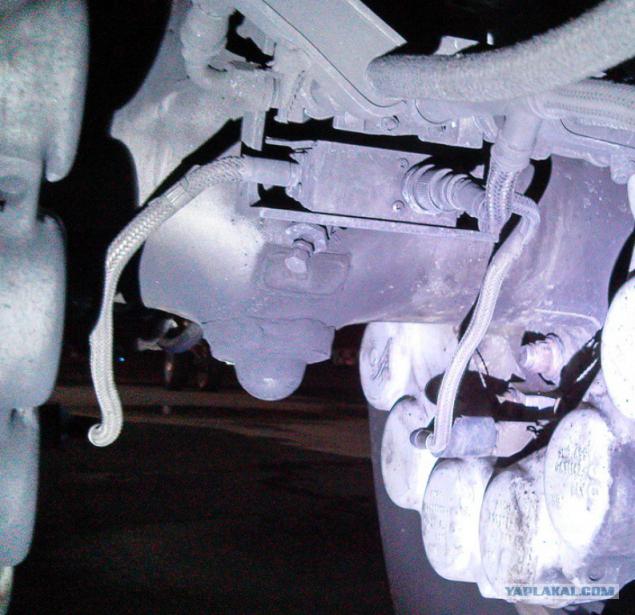

Amortstoyka below:

In the middle of the picture is visible hemisphere - a place setting lifts the replacement of wheels and brakes.

Above - fitting amortstoyki filling with nitrogen (this is the bottom, there are even higher at the front).

The letter 1 designates BTMU (Brake Temperature Monitoring Unit = Unit temperature monitoring brakes).

It is connected through connectors with temperature sensors in the brakes,

and transmits the signal somewhere further into the depths.

As a result, temepraturka comes up on the bottom, the system, the display ECAM.

Note that the brake temperature is measured relative to ambient temperature.

About braking the front wheels.

Service brake when cleaning your brakes hydraulic oil supply.

The front is not inhibited in any way.

Earlier on older Airbus established a niche in front chassis on the ceiling stretched tape on the wheels where the brakes after harvest; Now this is not.

On the Boeing-737 ceiling front niches have textolite pad for braking the wheels.

Perhaps this brake about I finish.

Not considered braking system, but would like to show it as a brake assembly.

Stsyl. All !!!

Today we look Jets brake.

Brakes different planes are very similar to each other and to the parts of the structure are slightly different - basically a method of attaching to the axis.

We will study the brake by Airbus-320.

The brake can be supplied in various transport package; for example, here in this.

24 photo.

Weighs such a thing about 100kg, of which approximately 70 kg - the brake itself.

Here it is in all its glory:

As can be seen, brakes - disc.

Specifically, this model contains four mobile and fixed five discs.

Discs - carboxylic and are lined with a metal slot for connection with the splines of the wheel.

Before installing the wheels aligned wheels and wheel their slots fits into these grooves.

On the inside of the wheel can be seen shining heat shield.

When braking, the brakes of the aircraft can be heated to 300 degrees or more, and the screen helps to lower heating disc wheels and tires.

Cooled brake through the holes in the rim or naturally:

Or can be mounted on the wheel cover with a fan for forced cooling:

Axial fan driven by an electric motor inside the axis sucks air from outside

and drives it through the holes in the wheels on, through the brake discs towards amortstoyki.

The hydraulic part of the brake cylinders provided housing.

Hydraulic cylinders then 14 - seven on the primary and secondary braking system, located in one.

Here it is clearly seen that the systems do not work simultaneously

(One piston is not involved, the other pushes the wheels)

The upper cylinders are fittings for venting air pockets after installing brake:

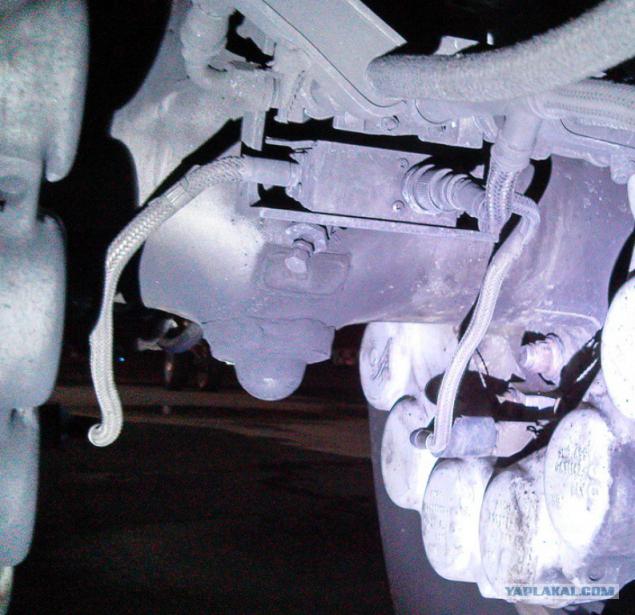

Hydraulic fluid to the collectors and the main alternative systems supplied by Connectors:

It is, without exaggeration, the great, the invention makes it possible to disconnect the hydraulic hoses for a couple of seconds.

It does not Contra and just need to turn the hose connector, to withdraw from the engagement to pin on the brake, and remove.

The brake wear indicator has two discs - front and back.

These pins (pins) attached sticking out of the slot in the housing.

When the brake is worn down to the need to replace, the protrusion of the pins for the plane body will be zero:

Naturally, it is necessary to check the wear on compressed disks. This is usually done with the parking brake on.

Pina there are different because different manufacturers sfotkatsya brakes.

After removal of the brake wear it is sent to the bulkhead. There, his clean, controlled and set new wheels.

Downstairs has a brake temperature sensor:

Fasten the brakes on different planes differently.

737 Classic brake bolted. It seems the 12th. Each bolt had to be tightened in two stages - first pull one point of bolts (not nuts) diagonally, and then - big moments in a circle. That more fun :)

At 737 NG brake at all luxurious. He was not screwed anything :) - Keep only by pressing the wheel, and the moment takes a hefty rectangular bar sticking out of amortstoyki. Brake when replacing a worn it.

A brake on the A320 is at an intermediate stage of evolution :) - he screwed all three nuts.

A moment from braking is transmitted to the rack through the three bolts, plus nine pins that are simply put on the brake when you install.

Here are the pictures just seen the bottom two nuts and among one of the nine pins.

The upper fixing nut (arrow)

inconveniently located, just opposite the stem amortstoyki.

Therefore, to replace the brakes need to have a torque wrench with an extension cord and head falling exactly into the small space between the counter and the brake housing :)

And in the end, as usual, to scare you ugly :)

Here is the lower part of the back amortstoyki:

We observe in the foreground two hydraulic hose on each side - the left and right brakes;

between them - a cable with wires of the temperature measuring system of brakes, power fans and sensors tachometer wheel (also located inside the axis of the rack).

I would like to respond immediately and prevent issues.

Why is all that dirty.

Ladies.

Sorry, blah.

Such is life.

The chassis is always very dirty.

This fine dust from wear carboxylic drives all flying here.

The plane slows down its 60 tons from 230 km / h to zero in a minute - what do you want?

Sticks and just dust.

Plus here blows grease. And sometimes a little hydraulic oil.

The only touch of this Heri immediately stain your hands for a few days. Their otmoesh FIG.

So - on all planes. Any companies.

I understand that I break your dreams of a white liner, but if you want to know how the materiel in fact - it's so she arranged.

There glamorous interior that fag gang cleaners after each arrival, and there is the chassis.

And then there are the fuselage, sometimes with streaks of hydraulic fluid and lubrication lyapami.

The world is.

Those who did not die from the truth of life, complete training.

Amortstoyka below:

In the middle of the picture is visible hemisphere - a place setting lifts the replacement of wheels and brakes.

Above - fitting amortstoyki filling with nitrogen (this is the bottom, there are even higher at the front).

The letter 1 designates BTMU (Brake Temperature Monitoring Unit = Unit temperature monitoring brakes).

It is connected through connectors with temperature sensors in the brakes,

and transmits the signal somewhere further into the depths.

As a result, temepraturka comes up on the bottom, the system, the display ECAM.

Note that the brake temperature is measured relative to ambient temperature.

About braking the front wheels.

Service brake when cleaning your brakes hydraulic oil supply.

The front is not inhibited in any way.

Earlier on older Airbus established a niche in front chassis on the ceiling stretched tape on the wheels where the brakes after harvest; Now this is not.

On the Boeing-737 ceiling front niches have textolite pad for braking the wheels.

Perhaps this brake about I finish.

Not considered braking system, but would like to show it as a brake assembly.

Stsyl. All !!!