Workshop "Peregrine"

Bashny.Net

Bashny.Net

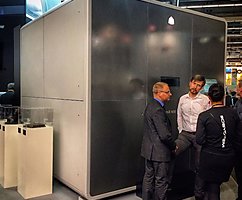

How to go "Sapsan", we know. They go quickly) How to look inside / outside, we too know. Today, the menu a little bit photo depot, which serves Siemens. Will be 50 photos in HD-resolution (1920h1080rh). A selection please do not break.

ZY I apologize for the quality of some pictures.

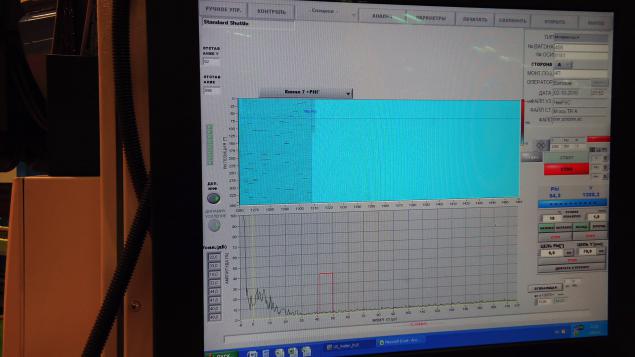

001. "Eight" (you can see the number of staff - "EMU 1-08") is quietly, waiting for something. To the right are two more ways.

002. The composition is a bottom view of the so-called ditch. The height (depth) - about 1, 5 meters, just do not know.

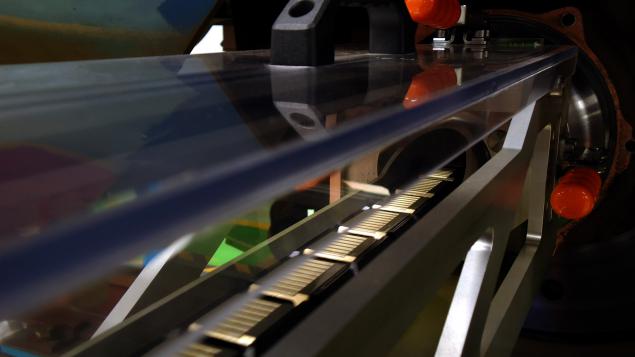

003. flaw "Sapphire", a device for ultrasonic testing of wheel sets (that the wheels themselves axis controlled separately). In the photo - the bottom half of that goes on under the ditch structure. The cost of this miracle - a seven-digit figure, expressed in US dollars.

004. The Germans are so well know Russian

005. Control for "Sapphire". Axis - a version of Windows for touch devices. Without charging runs about an hour, the range of - 50 m, communication with the device - via Wi-Fi.

006. Such is the animal pushes the "Sapsan" on the depot.

007. "Sapphire", top view. The sign says that "here you can not advance." Top left visible rollers and mechanisms that raise the truck (two axles, four wheels) above the rails to a height of 15-20 cm. The rollers rotate wheeled pair, letting you control the entire surface of the wheel.

008. Test wheelset. Yellow design does not allow the axis slide with rollers and crash down, smashing an expensive machine ... Control axis test is done to control the train axles and after control. On the axis of the test applied in advance defects enabling "calibrate" the unit. If the test results of this axis before and after control of the train does not match, then the whole work goes down the drain, it is necessary to monitor new (at least 20 minutes per pair of wheeled).

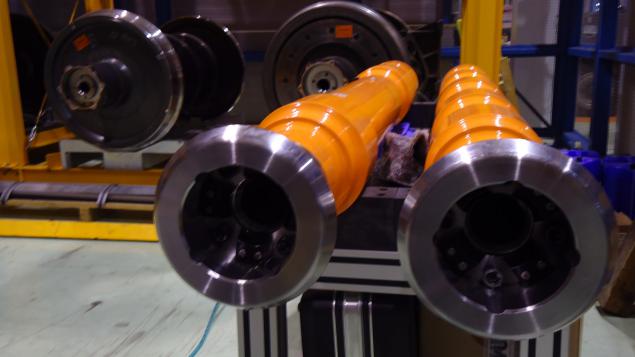

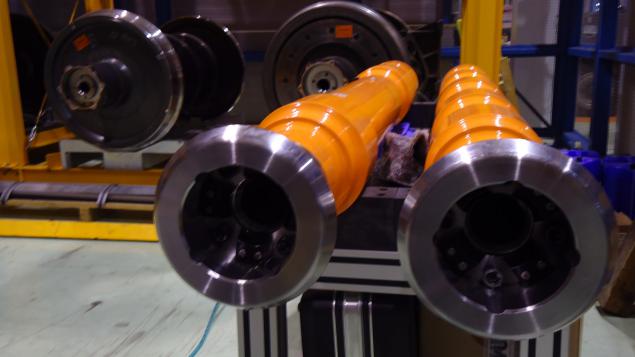

009. So looks ready to control the axis. By the way, the "Peregrine" axis of hollow, empty inside, while conventional trains are solid. Sami axis controlled by another device that will continue. On the axis of wearing a special adapter, which provides tightness and stiffness flaw.

010. Trolley, general view. On the left - ready to control the axis, to the right - a sealed, collected and untouched.

011. 4th car, 66 seats

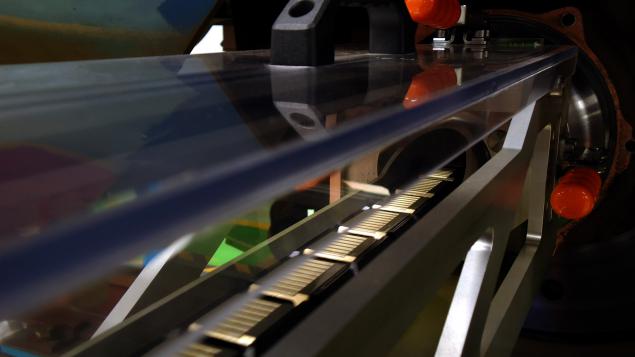

012. "Shuttle", the second of the two ultrasonic flaw in the depot. The sensors are connected and introduced into the axis, everything is ready for inspection.

013. The same, more general form. Wieden drum sensors.

014. A little closer.

015. More closer to the other side.

016. Suspension ... big, big shock

017. Sensors. Bravely, but slowly creeping into the lapped by oil.

018. Such is the flasher is on building "Space Shuttle".

019. "Shuttle", the overall look. Yellow garbage - remote control of hydraulic actuators, which move up and down the "plug" flaw. Left-right rotates freely.

020. Trolley with non-motorized axes. One can see the brake discs. And yes, they are outside of the motor axes.

021. The motor axis above the brake discs and indeed outside.

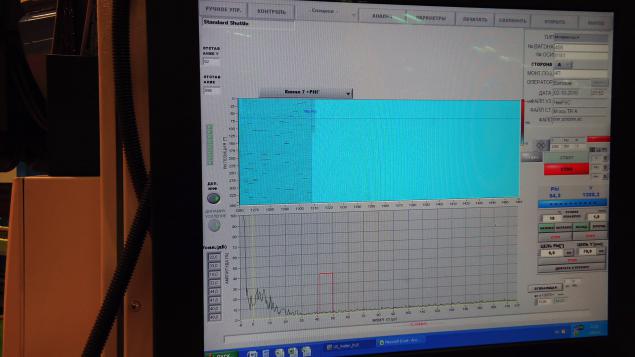

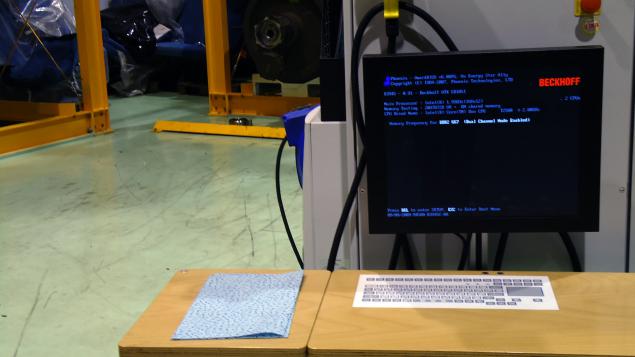

022. Management of "Space Shuttle" axis - Windows XP.

023. Warehouse shelves with new wheeled pairs.

024. The defective (faulty) axis. Nobody knows what to do with bad axles, because they are not amenable to repair, just melted. Damaged axle removed and left in a special storage, and what to do with them then - no one knows, including Siemens. And you say - Russian, Russian ... This mess is everywhere

025. The test axle. Their purpose described above.

026. The test axle and the "Space Shuttle". By the way, the machine weighs 700 kg and push it alone is not very nice. Visible to "mop" to clean the inner surface of which axis to control.

027. All the same test line. Motor (left) and non-motorized (right).

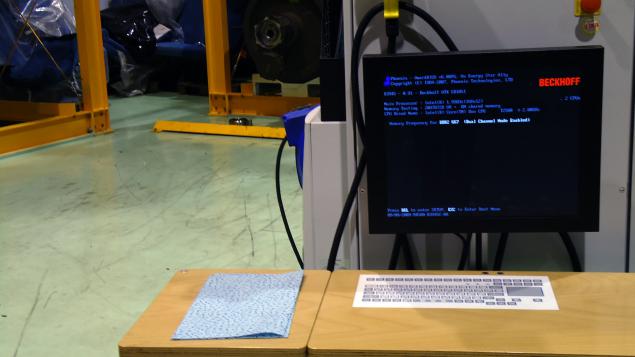

028. The computer controlling the "shuttle". The keyboard is not touch. Recessed into the table top and covered with a solid film. The keys are stiff and uncomfortable, but it is not terrible oil and other liquids. Well, the blue cloth that is wound onto the "mop." These wipes do not leave streaks and well absorb the fat.

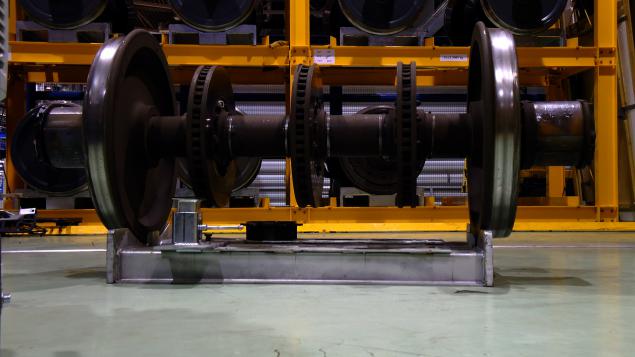

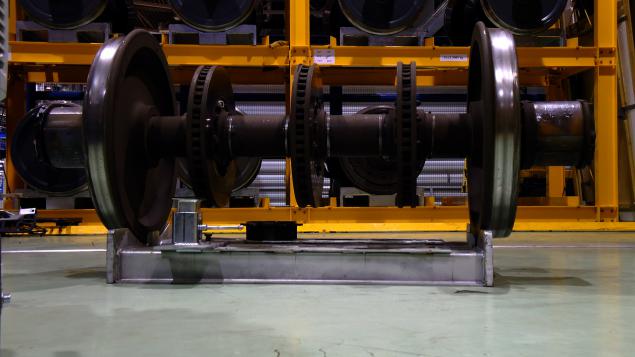

029. wheelset on the shelves.

030. We control the test axle ...

031. Closer.

032. A little further.

033. The two wheelsets. One such pair weighs about 800 kg, if I'm not mistaken. The very axis of more than 400, but the two wheels of 200 kg, excluding the brake discs on non-motorized axes. Truck assembly (two wheel pairs plus housing) weighs about 2 tons.

034. And there is quiet part of ...

035. While doing the test axes depot crept second composition having the number "EMU 1-07", ie "Seven."

036. creeps.

037. crawling

038

039. Depot, general view.

040

041

042. View of the ditch, a little closer than the first photo.

043

044. Check all systems. This composition after 4 hours should start from the Moscow railway station in St. Petersburg.

045. "Sapsan", bottom view

046. While inspecting these two compounds in the depot crawling third, "six".

047

048

049. As you can see, on the ways of hanging garlands. Red - high voltage is on the way. Green - no high voltage.

050. Depot, outside view, about two o'clock in the morning. By the way, it is in Metallostroy station Metallostroy, St. Petersburg. The building of the depot - the first building, if you count them from Moscow. Sometimes there appears Allegro, but I could not catch him. That's all I wanted to say.

Source:

ZY I apologize for the quality of some pictures.

001. "Eight" (you can see the number of staff - "EMU 1-08") is quietly, waiting for something. To the right are two more ways.

002. The composition is a bottom view of the so-called ditch. The height (depth) - about 1, 5 meters, just do not know.

003. flaw "Sapphire", a device for ultrasonic testing of wheel sets (that the wheels themselves axis controlled separately). In the photo - the bottom half of that goes on under the ditch structure. The cost of this miracle - a seven-digit figure, expressed in US dollars.

004. The Germans are so well know Russian

005. Control for "Sapphire". Axis - a version of Windows for touch devices. Without charging runs about an hour, the range of - 50 m, communication with the device - via Wi-Fi.

006. Such is the animal pushes the "Sapsan" on the depot.

007. "Sapphire", top view. The sign says that "here you can not advance." Top left visible rollers and mechanisms that raise the truck (two axles, four wheels) above the rails to a height of 15-20 cm. The rollers rotate wheeled pair, letting you control the entire surface of the wheel.

008. Test wheelset. Yellow design does not allow the axis slide with rollers and crash down, smashing an expensive machine ... Control axis test is done to control the train axles and after control. On the axis of the test applied in advance defects enabling "calibrate" the unit. If the test results of this axis before and after control of the train does not match, then the whole work goes down the drain, it is necessary to monitor new (at least 20 minutes per pair of wheeled).

009. So looks ready to control the axis. By the way, the "Peregrine" axis of hollow, empty inside, while conventional trains are solid. Sami axis controlled by another device that will continue. On the axis of wearing a special adapter, which provides tightness and stiffness flaw.

010. Trolley, general view. On the left - ready to control the axis, to the right - a sealed, collected and untouched.

011. 4th car, 66 seats

012. "Shuttle", the second of the two ultrasonic flaw in the depot. The sensors are connected and introduced into the axis, everything is ready for inspection.

013. The same, more general form. Wieden drum sensors.

014. A little closer.

015. More closer to the other side.

016. Suspension ... big, big shock

017. Sensors. Bravely, but slowly creeping into the lapped by oil.

018. Such is the flasher is on building "Space Shuttle".

019. "Shuttle", the overall look. Yellow garbage - remote control of hydraulic actuators, which move up and down the "plug" flaw. Left-right rotates freely.

020. Trolley with non-motorized axes. One can see the brake discs. And yes, they are outside of the motor axes.

021. The motor axis above the brake discs and indeed outside.

022. Management of "Space Shuttle" axis - Windows XP.

023. Warehouse shelves with new wheeled pairs.

024. The defective (faulty) axis. Nobody knows what to do with bad axles, because they are not amenable to repair, just melted. Damaged axle removed and left in a special storage, and what to do with them then - no one knows, including Siemens. And you say - Russian, Russian ... This mess is everywhere

025. The test axle. Their purpose described above.

026. The test axle and the "Space Shuttle". By the way, the machine weighs 700 kg and push it alone is not very nice. Visible to "mop" to clean the inner surface of which axis to control.

027. All the same test line. Motor (left) and non-motorized (right).

028. The computer controlling the "shuttle". The keyboard is not touch. Recessed into the table top and covered with a solid film. The keys are stiff and uncomfortable, but it is not terrible oil and other liquids. Well, the blue cloth that is wound onto the "mop." These wipes do not leave streaks and well absorb the fat.

029. wheelset on the shelves.

030. We control the test axle ...

031. Closer.

032. A little further.

033. The two wheelsets. One such pair weighs about 800 kg, if I'm not mistaken. The very axis of more than 400, but the two wheels of 200 kg, excluding the brake discs on non-motorized axes. Truck assembly (two wheel pairs plus housing) weighs about 2 tons.

034. And there is quiet part of ...

035. While doing the test axes depot crept second composition having the number "EMU 1-07", ie "Seven."

036. creeps.

037. crawling

038

039. Depot, general view.

040

041

042. View of the ditch, a little closer than the first photo.

043

044. Check all systems. This composition after 4 hours should start from the Moscow railway station in St. Petersburg.

045. "Sapsan", bottom view

046. While inspecting these two compounds in the depot crawling third, "six".

047

048

049. As you can see, on the ways of hanging garlands. Red - high voltage is on the way. Green - no high voltage.

050. Depot, outside view, about two o'clock in the morning. By the way, it is in Metallostroy station Metallostroy, St. Petersburg. The building of the depot - the first building, if you count them from Moscow. Sometimes there appears Allegro, but I could not catch him. That's all I wanted to say.

Source:

Tags

See also

18 packages, which were even steeper than the products themselves

Bayview subway station in Toronto

Discreet and not yell at a child ... Well here is how?

The boat in pos.Makarevo or Topograv, Be-Be-Be)

Cue: medical diagnostics at home

Advanced sex — learn the secrets!

The Maginot Line: underground shelter in the forests of Lorraine

What's inside

9 houses that looks awful from the outside but inside Terrific!