Insulation of floor in a wooden house

Bashny.Net

Bashny.Net

Today we look at one of the most popular schemes for the device heat-insulated floor in the wooden house. The review will raised key questions about the preparation and structure of the substructure of the floor, a cake of insulation and its protection and about the right flooring from natural boards.

Requirements to the supporting floor systemhigh-Quality insulation of wooden floor requires the compliance of the configuration of the subsystem (Las, towers, bridges) of the existing size and form factor of the insulation. Most suitable for insulation of wooden floor are polystyrene and mineral wool, are used less frequently bulk granular fillers like cellulose fibre or perlite aggregate.

The design of the base floor system must allow you to securely fix the insulation, ensure it stable and will retain its strength and functionality.

The key to the device is reliable and durable under floor heating is a good fixing the lag and providing a solid support for them. If the floor is arranged on the ground, you must place a number of supporting pillars, built of brick or cast concrete. To simplify installation, the edges of the lag based on the tabs in the tape base. They can be made with drills and angle GRINDERS, but after the patch with cement mortar, or to provide for the Assembly of the formwork. Between the end of the rod and the whole Foundation needs to remain the expansion gap of the order of 1/4% of the length of the joists.

You also need to make sure that the moisture contained in the stone elements of the structure — the foundations and supporting pillars — will not migrate into the wood. To do this, use pads of 2-3 layers of rolled waterproofing. Should focus on treatment of the wood before starting installation work. All the timber should be impregnated with antiseptics and, if necessary, flame retardants, and then dried in the stacks.

The joists and counter lathingWith installation of the lag they have with a step corresponding to the format of the used insulation. To avoid the frequent installation of support poles, you can use the system of cross-lag. In this case, the lower bars have the cross section with equal sides and perform the majority of the carrier function. The top row has a frame device: the boards set on edge to form the longitudinal cells, convenient for laying of insulation of a certain width and fastening flooring boards.

If the house is on slab Foundation, load-bearing floor system is the simplest device. The joists are formed one next frame, which is anchored to the concrete base. The plane of the monolithic Foundation forms a bottom for the cells under the insulation, providing its reliable fixing.

When flooring on the ground of a similar reference plane is not available. One of the options to arrange it to run a light coating of porous material such as expanded perlite or expanded clay to the bottom of the joists.

Otherwise, the joists that form the cells for insulation, provided with longitudinal stops. The bar is about 25x25 mm fastened with screws at the bottom of each joists, forming parallel ledges. Fit mesh of shingles or thin cutting Board, which provides support and insulation.

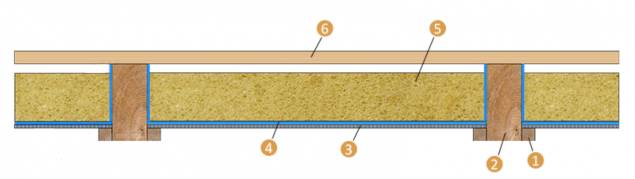

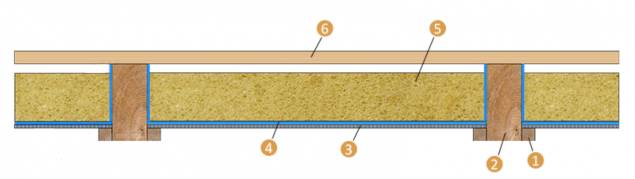

1 — cranial bar; 2 — lag floor; 3 — grid; 4 — insulation; 5 — heater; 6 — floor Board

It is important to know that since filled the bars a little "eat" the space of the cell floor, the remaining height may not be enough to accommodate the insulation of such thickness that provides thermal calculation. In this case, the bars of the same size over stuffed rib frame system. They can be placed in parallel or across the top row of the lag, in the latter case provides additional clearance for ventilation of the insulation.

Tab insulationWidth of cells under a laying of mats of mineral wool should be 1-2% smaller than the insulation. Due to the tight fit eliminates excessive air flow through the floor and kompensiruet possible shrinkage of the wool over time. When laying the mats they need to squeeze gently and evenly across the plane, to invest in the cavity and then spread inside. It is desirable that after installation the wool formed a small hump, protruding upwards, which will hold the boards. If you use foil wool, it is a reflective surface up.

In the case of polystyrene, which is virtually not compressible, the formation of minor gaps. Eliminate them, blowing out their summer foam after filling in all the cells. Too thick for the clearances to reduce the consumption of foam can be removed with fine carved panels of PPPs.

For filling the insulation in the space between the joists need to locate a cell prostili the bottom of the vapor permeable membrane Welt turned on wooden blocks. In the simplest version you can use the geotextile or vapor barrier to protect the roof. To exclude a shift of the membrane during the filling of the insulation, it is recommended to shoot brackets to the wooden elements of the floor system.

How is the protection of heat insulationVarious insulation and ventilation can require that the limited space under the floor to circulate the air. This is especially true for the combined piled-raft foundations where the insulation is in contact with outdoor air and should be protected from getting wet.

Below mineral wool does not lose heat-saving properties when saturated with moisture, its shelter on top of the vapor barrier. Protective membrane is spread over the joists and insulation, then fixed to wood with small nails or staples. The joints should be carefully glued on both sides, better if they are to be exactly positioned on the edges of the carrier system of the floor.

In those rare cases when the dew point may move above the insulation with condensation on the vapor barrier, is required to provide produh under the decking boards. You need to fill on top of the frame lag, covered with vapor barrier, kontrobreshetku from boards of the same width as the joists themselves. The thickness of the produh usually does not exceed 20-25 mm, the counter lathing does not affect the quality of the fastening of decking boards.

Plank floorboards, the insulated frame floor System has elements of solid wood, are an excellent cold bridges. In order to prevent the outflow of heat, you can cover frame floor system insulating and moisture resistant material such as GULU or IPF, and then lay boards, pre-planned position of the Arab League.

For floor heating it is recommended to use grooved Board with expansion slots on the reverse side. Such flooring will not creak when walking, it is less prone to uneven shrinkage and warping. Due to the tight matching of the boards eliminates any kind of blowing between them. If under the floor it is planned a limited air circulation, holes for its tributary will serve as a remote gaps of 10-15 mm at the walls, serving also to compensate for linear expansion of the wood.

When the flooring from the end of the first Board is cut, the crest, a groove is oriented to him. The bonding is performed at each lag by one or two points. Fixed Board has finished nails, which hammer obliquely into the groove and finish instructing a steel rod. For the quality of rallying the planks at 20-30 cm in front of them to the joists to temporarily hold the bar and squeeze him loose floorboards lever or car Jack.

The last Board of the set is cut off in accordance with the size of the remaining gap, taking account of the curvature of the walls. It is squashed from the wall with a pry bar through the lining of the block of wood, and then fastened to the joists through directly from the surface. Marks for nailing later be covered with skirting. published

Source: www.rmnt.ru/story/isolation/1252596.htm

Requirements to the supporting floor systemhigh-Quality insulation of wooden floor requires the compliance of the configuration of the subsystem (Las, towers, bridges) of the existing size and form factor of the insulation. Most suitable for insulation of wooden floor are polystyrene and mineral wool, are used less frequently bulk granular fillers like cellulose fibre or perlite aggregate.

The design of the base floor system must allow you to securely fix the insulation, ensure it stable and will retain its strength and functionality.

The key to the device is reliable and durable under floor heating is a good fixing the lag and providing a solid support for them. If the floor is arranged on the ground, you must place a number of supporting pillars, built of brick or cast concrete. To simplify installation, the edges of the lag based on the tabs in the tape base. They can be made with drills and angle GRINDERS, but after the patch with cement mortar, or to provide for the Assembly of the formwork. Between the end of the rod and the whole Foundation needs to remain the expansion gap of the order of 1/4% of the length of the joists.

You also need to make sure that the moisture contained in the stone elements of the structure — the foundations and supporting pillars — will not migrate into the wood. To do this, use pads of 2-3 layers of rolled waterproofing. Should focus on treatment of the wood before starting installation work. All the timber should be impregnated with antiseptics and, if necessary, flame retardants, and then dried in the stacks.

The joists and counter lathingWith installation of the lag they have with a step corresponding to the format of the used insulation. To avoid the frequent installation of support poles, you can use the system of cross-lag. In this case, the lower bars have the cross section with equal sides and perform the majority of the carrier function. The top row has a frame device: the boards set on edge to form the longitudinal cells, convenient for laying of insulation of a certain width and fastening flooring boards.

If the house is on slab Foundation, load-bearing floor system is the simplest device. The joists are formed one next frame, which is anchored to the concrete base. The plane of the monolithic Foundation forms a bottom for the cells under the insulation, providing its reliable fixing.

When flooring on the ground of a similar reference plane is not available. One of the options to arrange it to run a light coating of porous material such as expanded perlite or expanded clay to the bottom of the joists.

Otherwise, the joists that form the cells for insulation, provided with longitudinal stops. The bar is about 25x25 mm fastened with screws at the bottom of each joists, forming parallel ledges. Fit mesh of shingles or thin cutting Board, which provides support and insulation.

1 — cranial bar; 2 — lag floor; 3 — grid; 4 — insulation; 5 — heater; 6 — floor Board

It is important to know that since filled the bars a little "eat" the space of the cell floor, the remaining height may not be enough to accommodate the insulation of such thickness that provides thermal calculation. In this case, the bars of the same size over stuffed rib frame system. They can be placed in parallel or across the top row of the lag, in the latter case provides additional clearance for ventilation of the insulation.

Tab insulationWidth of cells under a laying of mats of mineral wool should be 1-2% smaller than the insulation. Due to the tight fit eliminates excessive air flow through the floor and kompensiruet possible shrinkage of the wool over time. When laying the mats they need to squeeze gently and evenly across the plane, to invest in the cavity and then spread inside. It is desirable that after installation the wool formed a small hump, protruding upwards, which will hold the boards. If you use foil wool, it is a reflective surface up.

In the case of polystyrene, which is virtually not compressible, the formation of minor gaps. Eliminate them, blowing out their summer foam after filling in all the cells. Too thick for the clearances to reduce the consumption of foam can be removed with fine carved panels of PPPs.

For filling the insulation in the space between the joists need to locate a cell prostili the bottom of the vapor permeable membrane Welt turned on wooden blocks. In the simplest version you can use the geotextile or vapor barrier to protect the roof. To exclude a shift of the membrane during the filling of the insulation, it is recommended to shoot brackets to the wooden elements of the floor system.

How is the protection of heat insulationVarious insulation and ventilation can require that the limited space under the floor to circulate the air. This is especially true for the combined piled-raft foundations where the insulation is in contact with outdoor air and should be protected from getting wet.

Below mineral wool does not lose heat-saving properties when saturated with moisture, its shelter on top of the vapor barrier. Protective membrane is spread over the joists and insulation, then fixed to wood with small nails or staples. The joints should be carefully glued on both sides, better if they are to be exactly positioned on the edges of the carrier system of the floor.

In those rare cases when the dew point may move above the insulation with condensation on the vapor barrier, is required to provide produh under the decking boards. You need to fill on top of the frame lag, covered with vapor barrier, kontrobreshetku from boards of the same width as the joists themselves. The thickness of the produh usually does not exceed 20-25 mm, the counter lathing does not affect the quality of the fastening of decking boards.

Plank floorboards, the insulated frame floor System has elements of solid wood, are an excellent cold bridges. In order to prevent the outflow of heat, you can cover frame floor system insulating and moisture resistant material such as GULU or IPF, and then lay boards, pre-planned position of the Arab League.

For floor heating it is recommended to use grooved Board with expansion slots on the reverse side. Such flooring will not creak when walking, it is less prone to uneven shrinkage and warping. Due to the tight matching of the boards eliminates any kind of blowing between them. If under the floor it is planned a limited air circulation, holes for its tributary will serve as a remote gaps of 10-15 mm at the walls, serving also to compensate for linear expansion of the wood.

When the flooring from the end of the first Board is cut, the crest, a groove is oriented to him. The bonding is performed at each lag by one or two points. Fixed Board has finished nails, which hammer obliquely into the groove and finish instructing a steel rod. For the quality of rallying the planks at 20-30 cm in front of them to the joists to temporarily hold the bar and squeeze him loose floorboards lever or car Jack.

The last Board of the set is cut off in accordance with the size of the remaining gap, taking account of the curvature of the walls. It is squashed from the wall with a pry bar through the lining of the block of wood, and then fastened to the joists through directly from the surface. Marks for nailing later be covered with skirting. published

Source: www.rmnt.ru/story/isolation/1252596.htm

Tags

See also

Wooden house in Norwegian style

Wooden house: the optimal combination of reliability, durability and cost

The walls of the frame house: the correct pie of warming

How to insulate the dacha with his hands

How to make warm water floor with their hands

Painting a wooden house. How to protect your fortress

Wooden porch for eco house with his own hands

What is IMPORTANT to consider the construction of a log home