The Russians make the medals for the 2014 Olympics

Bashny.Net

Bashny.Net

Before the Olympic Winter games in Sochi is 210 days, and the manufacture of Olympic medals at the jewelry factory "Adamas" in Moscow continues quite rapidly. All will be done 1 300 gold, silver and bronze medals, which will take not less than three kilograms of gold of 999 tests, two tons of silver 960 samples and 700 kilograms of bronze. This substantial difference in the amount of precious materials due to the fact that gold medals are not actually gold and that the gold they are made of silver, and then covered with six grams of gold.

All of the materials used for the needs of the Olympic games, produced on the territory of Russia, and the medals carry only Russian specialists. Produce medals in a separate workshop; there the medals are all the stages of cooking, from cutting round blanks up to the last sanding. The technological process for each coin involves 25 stages.

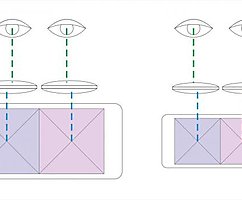

Most of them related to the processing of the metal blank (20 operations), and the rest — machining of polycarbonate (used to make the insert in the form of a quilt — one of the symbols of the Olympics-2014). Manufacturer of medals starting with casting, rolling and cutting of the workpiece, the end face of the metal squares of silver or bronze (depends on the dignity of the medal) with the dimensions of 12 by 12 cm and a thickness of 12 mm. Then on a modern lathe from a square, make a round billet with a diameter of ten centimeters.

Then the billet is sent to the mill, where the applied patterns, the symbols, the names of subjects. A method of high speed milling to prepare the pocket for the fastening tape. Then medals make-UPS will be placed polycarbonate crystals. After this award several times sanded, and cleaned — up to the final.

Source: /users/413

All of the materials used for the needs of the Olympic games, produced on the territory of Russia, and the medals carry only Russian specialists. Produce medals in a separate workshop; there the medals are all the stages of cooking, from cutting round blanks up to the last sanding. The technological process for each coin involves 25 stages.

Most of them related to the processing of the metal blank (20 operations), and the rest — machining of polycarbonate (used to make the insert in the form of a quilt — one of the symbols of the Olympics-2014). Manufacturer of medals starting with casting, rolling and cutting of the workpiece, the end face of the metal squares of silver or bronze (depends on the dignity of the medal) with the dimensions of 12 by 12 cm and a thickness of 12 mm. Then on a modern lathe from a square, make a round billet with a diameter of ten centimeters.

Then the billet is sent to the mill, where the applied patterns, the symbols, the names of subjects. A method of high speed milling to prepare the pocket for the fastening tape. Then medals make-UPS will be placed polycarbonate crystals. After this award several times sanded, and cleaned — up to the final.

Source: /users/413

Tags

the Russians make the medal

medal for the Olympics

the production of medals

the basics of knowledge

video

photo

gold

bronze medals

medal

See also

How to make medals for the Olympics in Sochi in 2014 (14 photos)

As I was doing the sled snowmobile

"Tbilisi phenomenon": how to felon science

The beauty of your hands

As I developed a device for pumping cot

How to store honey — 8 useful tips

Let's get married: how celebrities make an offer

Russians and Muscovites

Important events of the year

As a sports photographers at the Olympics in Sochi