Up! Plus 2. Overview: unpacking, calibration, and analysis of the first printing

Bashny.Net

Bashny.Net

The first rule of working with Up! Plus 2: Preheat platform

Second rule: check, whether you're warmed platform

The third rule is to double-check whether you warmed platform i>

The Chinese company PP3DP i> closed issue printers first version ( Overview Habré first model: Up ! Plus) and now the Russian market to actually buy only UP! Plus 2.

In this topic try to highlight Unlike the first version (why it used to cost 70,000 and now 83.000?)

Look & quot; under the hood & quot ;, say a few words about the mode Surface , print out a shield from World of Warcraft (whether or not Printing occurs in 1 click? B >) and give a couple of recommendations for the use 3d printer.

(35 photos under the cut)

Refinement Room 1: soft mode lowering the platform - now do not have to jump from platform clanking sound fallen.

Fitch: a design feature of the extruder with a short delivery tube during printing allows quick and easy change of plastic string that is printed in different colors. (Together with the regime «pause», although if enough agility pumped - you can without it)

Comparing the size of the platform:

Beige - from Up! plus 1, black - Up! plus 2

Comes with 3 platform. Teflon coating. Of pure acetone. (Some special stocking igolochkoj ... for meditation).

For mounting platform no longer needs to be purchased at office supply store - included are a handy clip:

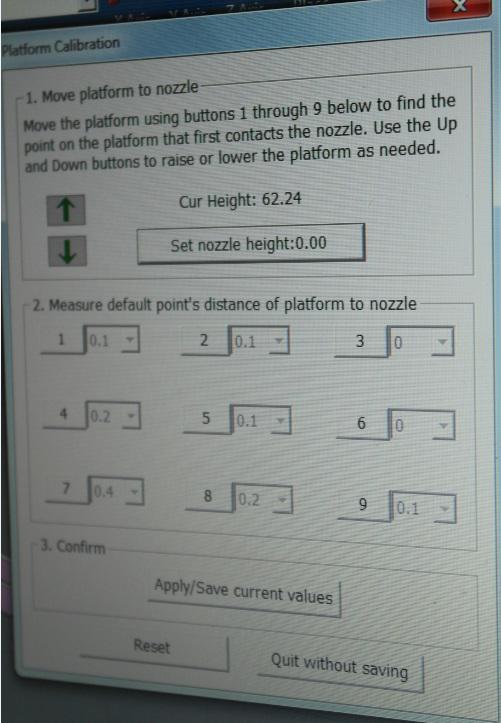

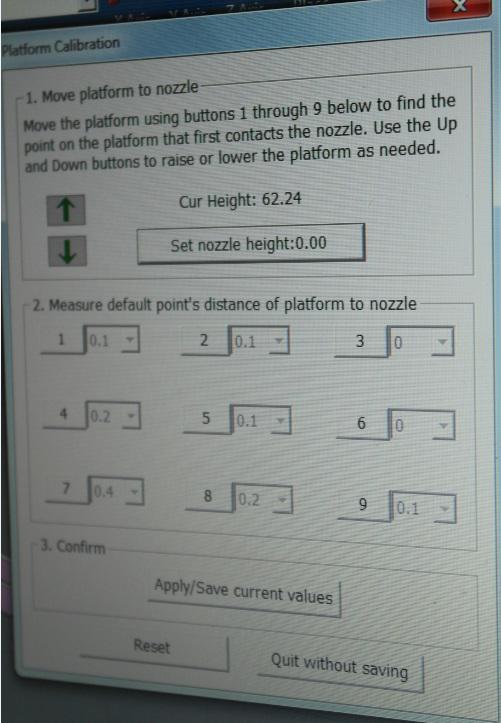

Nozzle calibration platform:

Autocalibration platform Auto Level i> - on the head with a magnet and he hung up the sensor probes away at random at 9 points.

Height sensor platform:

If earlier it was necessary to adjust the height of the nozzle, it is done manually. Now it is sufficient to connect the sensor cable to the platform with the connector on the back board of the printer and run the program Auto Nozzle High i>

New connector for sensor calibration (color / green-blue):

Fixed something that had a lot of complaints - an arm of the head (now not pognesh and cranky!):

Previously grind heaters platform, now the question is solved - flat ribbon cable:

The board has undergone revision:

Fee - new PCB. New quality of harassment and optimization of tracks. Molex used multicolored (blue to blue, yellow to yellow). All wires are removed in a braid.

The new processor 8000, programmed softer / smoother motion.

Photos old board to compare

Grounding (considering "stability" of the Russian ruble voltage, ground - a thick bolt on the board):

2-pin print head - you can put any extra fan or lighting:

(Left Up! Plus 2, Right Up! Plus 1)

The power supply (19, 5V, 9, 5A) was a little smaller, but still huge:

The left power supply conventional laptop, right - Up! Plus 1, centered Up! Plus 2

Mode Surface h4>

(picture from the site of the manufacturer) i>

Surface mode prints only the outer wall of the model ignoring the internal filling. For example, if a model of a closed cylinder will be printed "tube" with a wall thickness equal to the resolution of the layer. For example with a thickness of 150 to 150 and so on. In principle, the tricky location, you can print the closed balls. That is the model where the overlapping layers of less than 90 degrees are not included. The point is that this mode can best see the overall shape of the future model and print it in full size, compared with the others, much faster than in normal print settings. Of course, the model will be more fragile. Plus, the quality of the stacking layers will, in some cases even higher than stated by the manufacturer. I saw samples of printed items, where the layer thickness is 100 microns instead of the declared 150.

Calibration and automatic determination of the level h4>

Selecting the Auto Calibration menu:

The nozzle on the printhead in regard to platform 9 points:

The measurement data are entered into the program:

Auto-calibration is complete:

Automatic determination of the height of the printhead relative to the platform:

Printhead nozzle touch the sensor on the platform:

Height is defined:

Print the shield of World of Warcraft h4>

I recall that as in Up! Plus 1 and at Up! Plus 2 - their own software, which lacks mozgolomny stage with "Slicer».

Step 1: Downloading from the Internet model (http://www.thingiverse.com/thing:48069), or saves itself from WoW

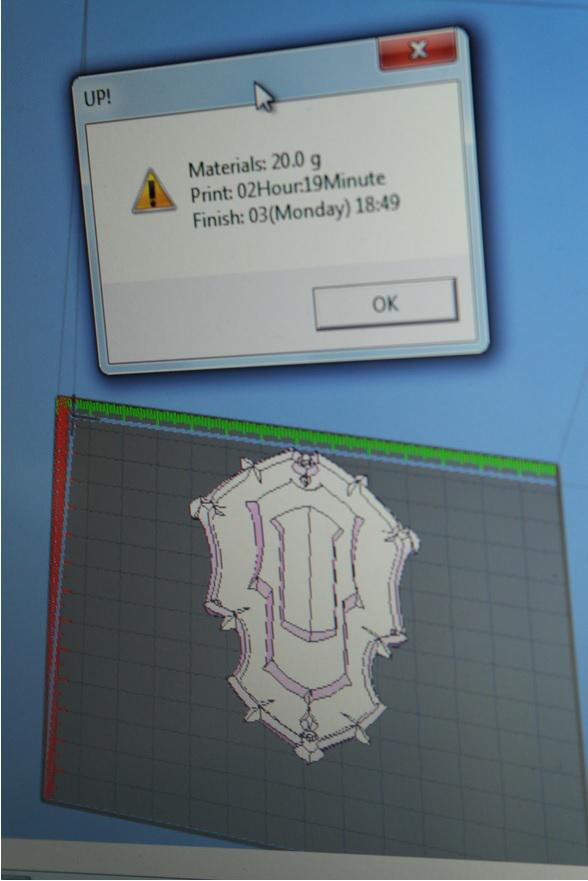

Step 2. Load the model in the print program (scalable and rotate if necessary)

Step 3. Warms platform

Step 4. Print

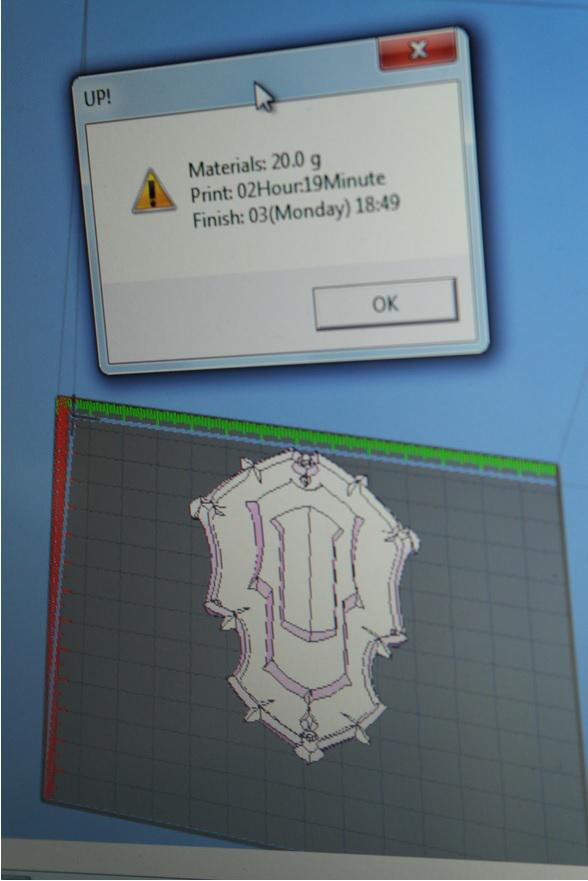

Estimation of the time of printing and plastic masses:

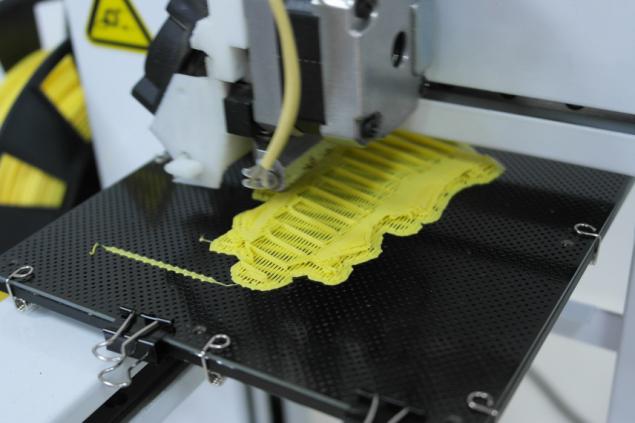

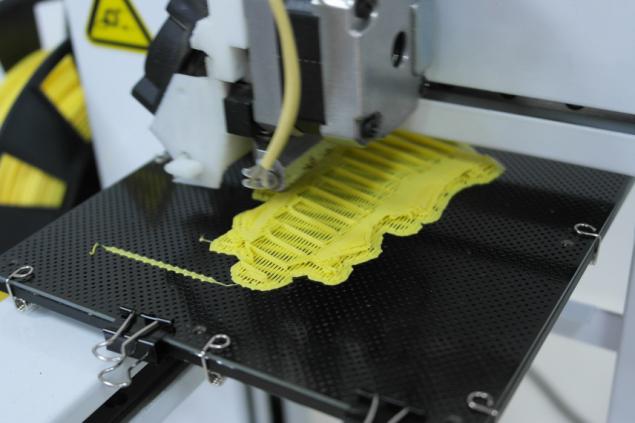

Start printing auxiliary layer on which the item will be placed:

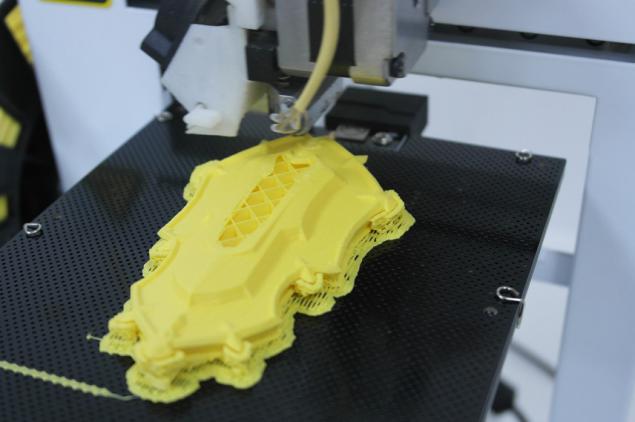

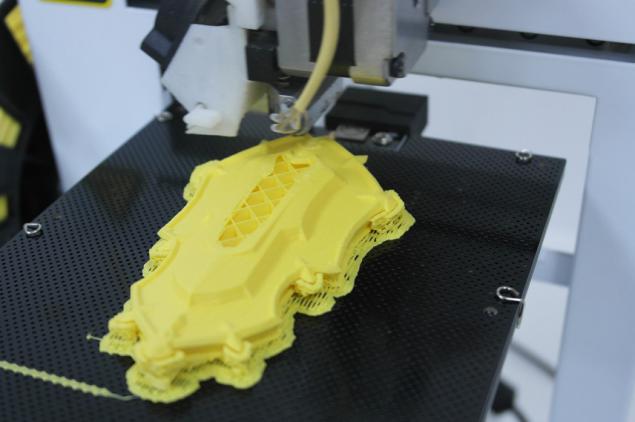

Shield of Lordaeron ready! B>

A few words about soft h4>

There are 2 types of printers: those who use the "open software" and those who use their own software.

And those and others have their own advantages.

Free Software claims to universality, the ability to improve the code and the ability to customize the "9000" parameter. Open software gives full freedom (in conjunction - full responsibility) to the user. If you're a fan settings to within microns and to a degree - it's a godsend for you. But you can insert the plastic from any manufacturer and for a while for him to get the optimum temperature printing.

Net software from the manufacturer 100% satisfaction guarantee "hardware" and software. Just own software from the manufacturer suggests that 95% of "9000" has already tweaked parameters technicians, professionals, and the company is responsible for it (somehow). Software from the manufacturer to avoid any additional software, several (tens, hundreds) of hours settings, and allows «unpack and print» i>

Developing their own software can afford only large companies (3d systems, Makerbot, PP3DP etc.) or some startups that make the software on a special rate.

Recommendations from Technical Support h4>

1. Remove the nozzle only on hot,

2. Use only the heated platform

3. It is for the coil because the "beard", is not only the fishermen

Conclusion:

- Printer - home. Small, cozy, handmade.

(Although I saw his excellent use of "commercial scale" - the room is worth a dozen of these brave guys and order prints from architects)

- Save time on the auto-calibration / determination of height

- Simple and convenient to send a print model

Source: habrahabr.ru/post/214649/

Tags

See also

How to build houses in the US (70 photos)

Sunbeam

The Chinese company Lingyun Technology introduced the second generation of its two-wheeled electric vehicles

Simple: bosons, fermions, quarks, and other elementary components of the Universe

The Chinese company "Youxia" is almost completely copied the electric car "Tesla"

The Chinese company Geely has bought British electric car and hybrids

Energy-efficient skyscrapers in the suburbs of Toronto

Chernobyl: 5 Things You Did not Know

The winners of the photo contest «Focus on Nature»