How to make beer. Moscow Brewing Company

Bashny.Net

Bashny.Net

29 ph + letter

via

2. First of all asked to wear special robes and hats, as it should be on food production. Then, given the special radio device with an earphone, like a car kit. This is one of the positive aspects will be pleasantly surprised. With this device has always been heard of the guide, even if the shop is noisy, even if you're behind. It was possible to watch and shoot at the same time not to miss valuable information.

3. Reception Marina charming tour guide told us about the plant's products.

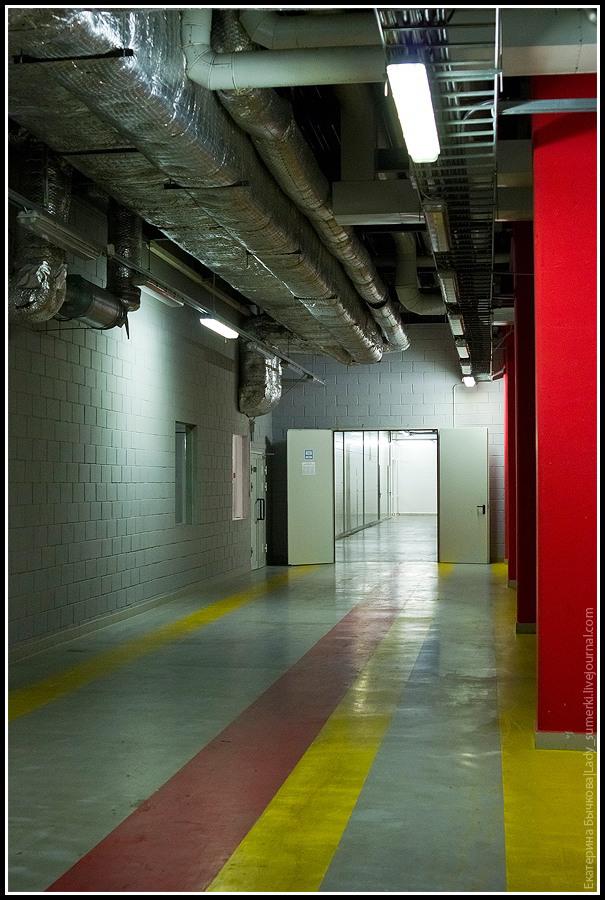

4. production all clear. We go to the production.

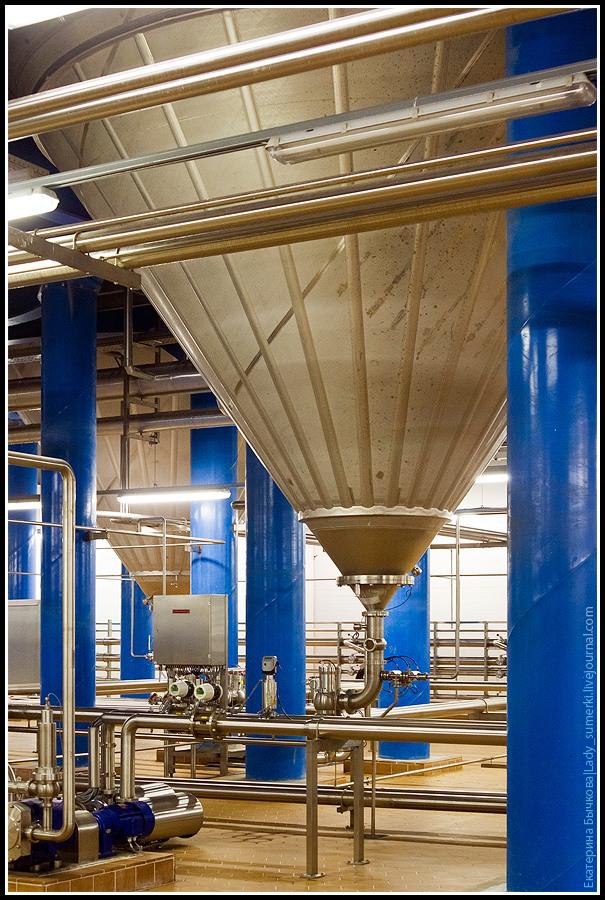

The holy of holies - the water treatment plant. Water - an important component of beer, because its share in the beverage is 90%. The place for construction of the plant was not chosen by chance. The proximity of the Pirogov reservoir clean, good ecology. But the water for the production plant takes not of the reservoir, not from municipal water intake. The plant has five deep wells, is currently used only 4. Water taken from a depth of 190 and 320 meters! Marina itself tasted the water and was surprised - the water is delicious.

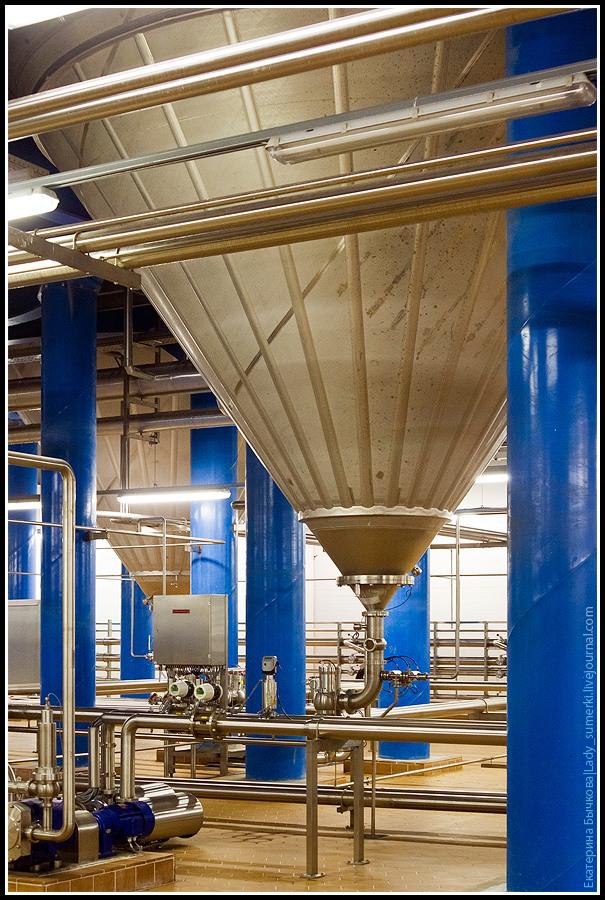

First, water is supplied to the receiver

5. Then passes several different filters. The last stage - this setting:

6. Inside are the membrane of the cell which in its size correspond exactly to the size of a water molecule. In fact, the output is distilled water. Distilled water, of course, can not drink. Therefore, the water is enriched with calcium, magnesium and other essential substances in the right proportions.

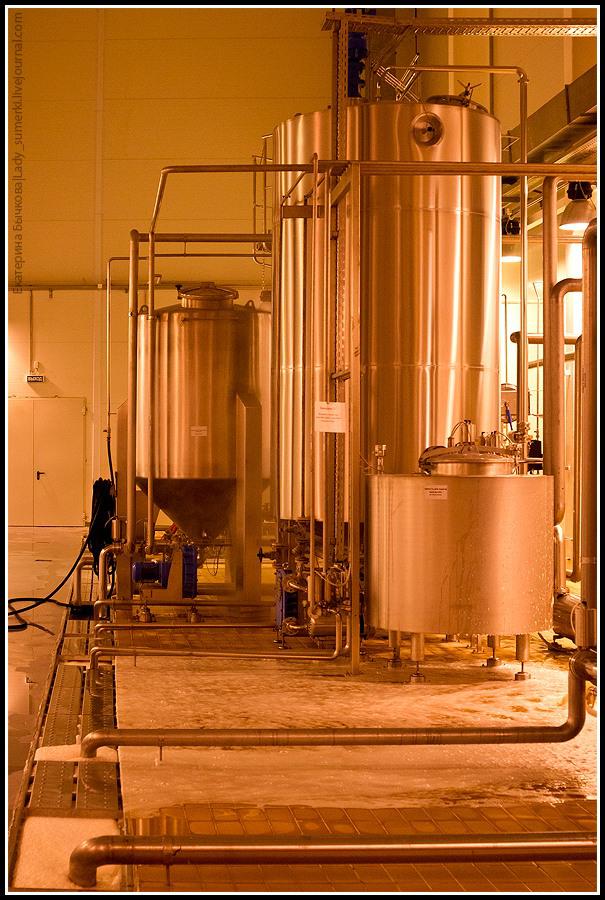

And the water is stored in huge tanks. in the photo are not visible tanks entirely, but it clearly shows that some tanks with a shell - some do not. The plating tank without normal stored water temperature. In tanks with a shell: Hot - for the production of wort and ice - to cool the wort.

7. In the shop can see traces of water treatment expansion. But more on that later.

8. Visit the brewhouse.

Let's take a closer look of what the finished beer. For the production of beer are needed: water, malt, hops and yeast. Malt - a specially processed grain germinated barley or wheat. Malt is different: light, dark, zhzhёnym and even caramel. From malt depends on the taste of beer. Different malt obtained by varying the processing of grain. For example, for a light malt grains is dried at a temperature of colo 250 degrees for half an hour. Ie the main differences - in the temperature and drying time. Caramel malt has a caramel flavor, because temperature and the processing time leads to the fact that the caramelized sugar grains. it is interesting that for some beers is not only malt, but just neproroschennoe grain.

The first stage of beer production - the preparation of the wort. First the malt is mixed with hot water. The process is called mashing process takes place here in this mash tank:

9. The second tank mash (smaller) is used for certain types of beer, which are made of two types of wort. For example, Moscow is preparing dvuhotvarochnym method.

Look inside.

10. Inside - with a very sweet mush:

11. Then the wort is filtered in a special setting, similar to an accordion. Drobin sent to the farm to feed cattle and pigs.

12. The resulting wort is boiled with hops. It turns out that hops does not allow alcohol, it has a sedative (relaxing) effect. If you do not sleep, you can hang above the bed bag with hops. The main thing is not to abuse! Beer used only female inflorescences of hops, not suitable for men. Hops is a bitter and aromatic varieties. So, they were never boiled together! If it is necessary to use two hops, the wort is boiled with first one, then - another.

13. Next, the wort is separated from the protein. This process is known as lightening. This is done by mixing the wort - collapsed in hot water protein remains in the bottom of the cone whirlpool.

14. Behind the glass - sitting operators. Reminds gym NPP))

15. Do not be fooled rags, etc. in the mash tank - now the factory is expanding, the tank still set. This is the second increase in the capacity of the enterprise. First, the plant was designed to produce 200 hectoliters per day, and then expanded to the production of 300 hectoliters, after the last performance will be the modernization of 540 hectoliters.

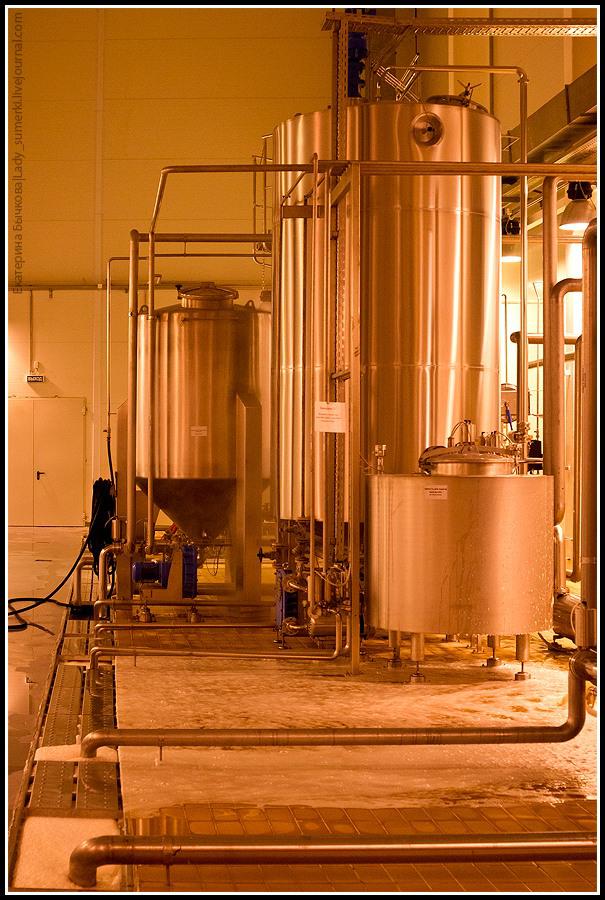

What happened at this stage of the proceedings, has not beer. This is a must. The wort is cooled and fed by numerous works on the first floor in the yeast department. When yeast is added to the wort, the mixture was fed to the fermentation plant. It is here that is born a beer. Formed alcohol, there is the aroma and taste.

16. Contrary to the expectations in the shop is not hot, and even cool. On the line there is a production of beer Zhiguli Bar, which is bottom-fermented beer, like most modern varieties known to us. Beer Nizwa called lager fermentation and matured at a temperature of -1 degree. Sometimes fermented beer - ales is, they ripen at a temperature of 15-25 degrees. Bottom-fermented beer can be enjoyed much more than the upland beer. In addition, it is quite stable - long sour, well-stored and transported. Lada Bar ripens 21 days. Week - the main fermentation, in which most of the sugar is converted into alcohol. Another 2 weeks - so called secondary fermentation, during which decomposes the residual sugar, and the yeast deposited on the bottom.

Tourists like to ask tricky questions. People often ask: "And in the summer heat when a large demand for the beer, not bottled it before? 21 days - it's a long time ... "Marina replied:" No. It is not the beer, we can not risk reputation. What to do? We are waiting for 21 days. " Proven sources say that in the summer of Zhiguli, however, it was very difficult to find in stores. Frequently asked questions about the addition of alcohol in the beer, because see barrels with an alcohol in the factory. But the alcohol in beer is added. The process of beer production requires an infinite sampling for samples and analyzes. Samples were taken through special air valves. But the process of production requires sterility. Therefore, after each sample air valves are filled with alcohol for disinfection. Cock very much, so alcohol is also very much necessary.

Rove beer in a tall, narrow tanks. The contents of one container in a diffuse and takes a packed train.

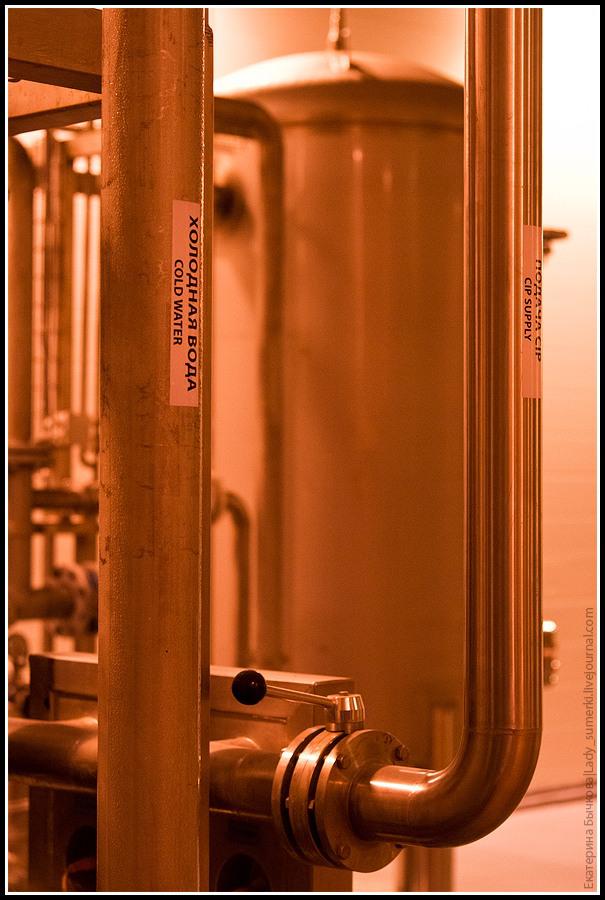

17. Next, the beer is sent to the filter. Unfiltered varieties respectively this stage do not pass. Yeast've already taken. During filtering the yeast from the beer finally removed, it becomes completely transparent.

18. We are almost swallowed foam, and we went on))

19. Many people ask about the unusual lighting in the shop filtration. No cunning plan - it just happened.

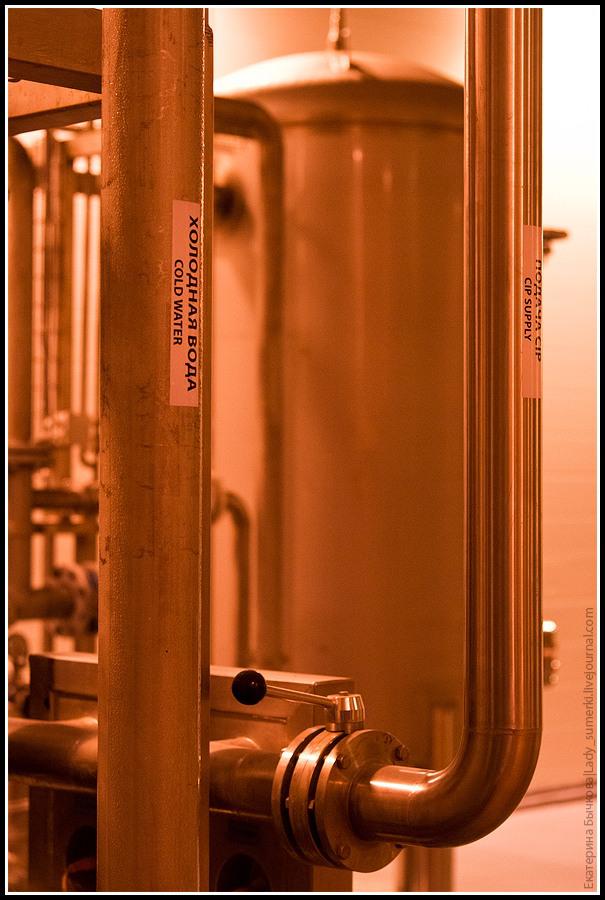

Another interesting point. Beer does not like oxygen, which is why for a long time an open beer becomes tasteless. Therefore, in the production process of oxygen ingress into beer suppressed. Oxygen is allowed once - in the wort with the addition of yeast to start the fermentation process. The shop is installing filtration dezaeratsii, which finally removes ksilorod caught in a drink at this stage of production.

20.

21. In the preparation of non-alcoholic beer is added another stage. Beer prepared, as usual, but in the finale of it evaporated alcohol.

Interestingly, if something went wrong, before filtering the beer can still be saved. After - already do. In this case, the spoiled beer poured down the drain. At the factory of the IPC it happened one time. The staff looked sadly at how cars merge into drains beer. According to rumors, it is not received at the plant, this time around Mytishchi almost every corner you can find natural point at which sold for mere pennies "beer just from the factory." Well, still live in Russia) Everything good can not disappear.

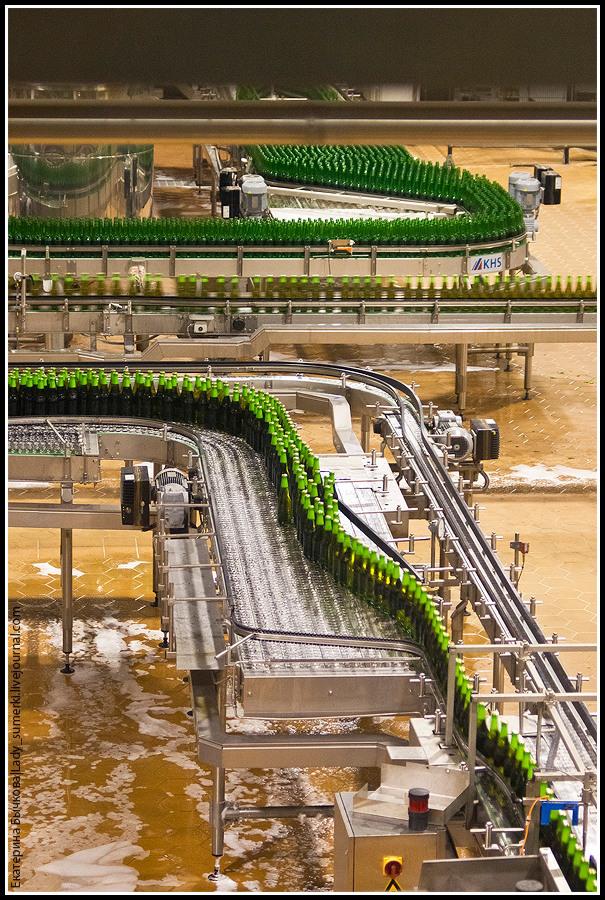

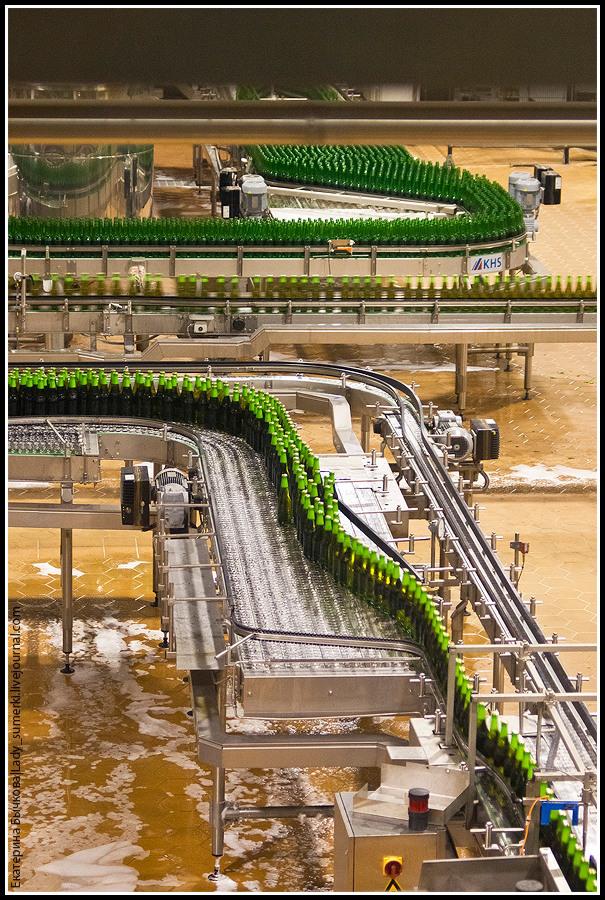

The finished beer is not added preservatives. Bottom-fermented beer itself is stored for a long time. To beer kept even longer, it is in the process of pasteurization: Very warm, aged about a minute, and then rapidly cooled. It does not live beer is pasteurized, so it tastes better, but few stores. Pasteurization occurs in the bottling hall. Here the beer is bottled (glass and plastic), banks and kegs.

22. IPC only uses the new packaging. They already have the equipment to use returnable containers. But the use of returnable containers costing the company more expensive than the use of a new one. Therefore, this equipment will be used only if the authorities at the legislative level, the company will be obliged to use the back container. Despite the fact that the packaging and checked for the new glass factory, where it is checked again. After all, even hairline cracks can occur during transport. A microcrack may affect the quality of the beer. When we have a special one flaw I discarded the bottle.

23. This central laboratory. Here, check the quality of the components and the finished beer.

24. This pipe bridge between different plant production:

25. The plant makes a very good impression. Everywhere beautiful, clean, everything shines. The staff at the production of the minimum - everything is automated as much as possible.

Looking at the production process, we go to evaluate the result at the tasting bar in the canteen.

26. This cozy.

27. We tried Zhiguli Barney Redhead villager) Unfortunately, was not connected with the keg Brezhnyakom. If there was Brezhnyak, we would have been able to try cutting beer. Cutting the beer - it's different kinds of beer, bloodshot layers due to the difference in density, and the skill of the bartender. When you drink, of course, the layers were mixed, giving unusual flavors, but first cutting the beer probably looks beautiful and unusual.

28. Lada Bar all liked Ginger villager. It is simply more familiar, beer, with characteristic bitterness. But Selyanka mood is also good. Sometimes I feel like such a gentle taste without bitterness. By the way, no matter how bitter or had a beer in their recipes and varieties, the bitterness should not dwell on the throat for more than 10 seconds. If a minute passed, and you still bitter - beer is something wrong.

Real men drink beer to sip 3, no matter how much it was poured)) First half drink in one gulp, then half of the half, and then the rest. They say that a good beer after every pull on the cup remains a foam ring.

From left villager. In Zhiguli not had time to focus. The partners say, too, were following.

29. In addition the foam should not sag uniformly and must like tufts. If you want to enjoy the taste of beer, it is not a snack roach, salty crackers and chips - a snack crumbs of white bread and simple dryers without additives. To compare a few beers, breaks gnaw the same drying and crackers. Professional tasters try the beer warm - torlko so can reveal all of his faults. But to drink beer in the fun it is imperative chilled to 12 degrees. We were shown "female" American beer Coors Light, it is recommended to be cooled to 8 degrees (the white mountains on the label turn blue). Interestingly, if the beer was heated and then cooled, the taste has changed irrevocably. It is therefore important to store beer. Beer does not tolerate vanity and drinking on the run. Drink beer need to slowly, in good company. Beer does not like dirty dishes. Especially not like fat. Even when you eat chips and greasy lips leans against the glass, beer taste spoiled. The beer is better to drink fresh. This is not a wine that time only benefit. Beer is like a man - it is aging. Beer does not like oxygen. If the beer is in the air for a long time, it spoils. So do not rush when drinking, but do not tighten hard. Fortress not depend on the color of beer. Dark beer is not stronger light. Strength depends on the recipe and the desire of the brewer. Dark beer, however, is often stronger than the light, but not because of the characteristics of malt. By the way, Brezhnyak light at 0, 3% stronger Brezhnyaka dark. beer in kegs kept longer because kegs have double walls, in fact it's a thermos. In the case of reverse kegami packaging used. Beer in cans and bottles should be the same taste. Bank should not give a metallic taste.

Source:

via

2. First of all asked to wear special robes and hats, as it should be on food production. Then, given the special radio device with an earphone, like a car kit. This is one of the positive aspects will be pleasantly surprised. With this device has always been heard of the guide, even if the shop is noisy, even if you're behind. It was possible to watch and shoot at the same time not to miss valuable information.

3. Reception Marina charming tour guide told us about the plant's products.

4. production all clear. We go to the production.

The holy of holies - the water treatment plant. Water - an important component of beer, because its share in the beverage is 90%. The place for construction of the plant was not chosen by chance. The proximity of the Pirogov reservoir clean, good ecology. But the water for the production plant takes not of the reservoir, not from municipal water intake. The plant has five deep wells, is currently used only 4. Water taken from a depth of 190 and 320 meters! Marina itself tasted the water and was surprised - the water is delicious.

First, water is supplied to the receiver

5. Then passes several different filters. The last stage - this setting:

6. Inside are the membrane of the cell which in its size correspond exactly to the size of a water molecule. In fact, the output is distilled water. Distilled water, of course, can not drink. Therefore, the water is enriched with calcium, magnesium and other essential substances in the right proportions.

And the water is stored in huge tanks. in the photo are not visible tanks entirely, but it clearly shows that some tanks with a shell - some do not. The plating tank without normal stored water temperature. In tanks with a shell: Hot - for the production of wort and ice - to cool the wort.

7. In the shop can see traces of water treatment expansion. But more on that later.

8. Visit the brewhouse.

Let's take a closer look of what the finished beer. For the production of beer are needed: water, malt, hops and yeast. Malt - a specially processed grain germinated barley or wheat. Malt is different: light, dark, zhzhёnym and even caramel. From malt depends on the taste of beer. Different malt obtained by varying the processing of grain. For example, for a light malt grains is dried at a temperature of colo 250 degrees for half an hour. Ie the main differences - in the temperature and drying time. Caramel malt has a caramel flavor, because temperature and the processing time leads to the fact that the caramelized sugar grains. it is interesting that for some beers is not only malt, but just neproroschennoe grain.

The first stage of beer production - the preparation of the wort. First the malt is mixed with hot water. The process is called mashing process takes place here in this mash tank:

9. The second tank mash (smaller) is used for certain types of beer, which are made of two types of wort. For example, Moscow is preparing dvuhotvarochnym method.

Look inside.

10. Inside - with a very sweet mush:

11. Then the wort is filtered in a special setting, similar to an accordion. Drobin sent to the farm to feed cattle and pigs.

12. The resulting wort is boiled with hops. It turns out that hops does not allow alcohol, it has a sedative (relaxing) effect. If you do not sleep, you can hang above the bed bag with hops. The main thing is not to abuse! Beer used only female inflorescences of hops, not suitable for men. Hops is a bitter and aromatic varieties. So, they were never boiled together! If it is necessary to use two hops, the wort is boiled with first one, then - another.

13. Next, the wort is separated from the protein. This process is known as lightening. This is done by mixing the wort - collapsed in hot water protein remains in the bottom of the cone whirlpool.

14. Behind the glass - sitting operators. Reminds gym NPP))

15. Do not be fooled rags, etc. in the mash tank - now the factory is expanding, the tank still set. This is the second increase in the capacity of the enterprise. First, the plant was designed to produce 200 hectoliters per day, and then expanded to the production of 300 hectoliters, after the last performance will be the modernization of 540 hectoliters.

What happened at this stage of the proceedings, has not beer. This is a must. The wort is cooled and fed by numerous works on the first floor in the yeast department. When yeast is added to the wort, the mixture was fed to the fermentation plant. It is here that is born a beer. Formed alcohol, there is the aroma and taste.

16. Contrary to the expectations in the shop is not hot, and even cool. On the line there is a production of beer Zhiguli Bar, which is bottom-fermented beer, like most modern varieties known to us. Beer Nizwa called lager fermentation and matured at a temperature of -1 degree. Sometimes fermented beer - ales is, they ripen at a temperature of 15-25 degrees. Bottom-fermented beer can be enjoyed much more than the upland beer. In addition, it is quite stable - long sour, well-stored and transported. Lada Bar ripens 21 days. Week - the main fermentation, in which most of the sugar is converted into alcohol. Another 2 weeks - so called secondary fermentation, during which decomposes the residual sugar, and the yeast deposited on the bottom.

Tourists like to ask tricky questions. People often ask: "And in the summer heat when a large demand for the beer, not bottled it before? 21 days - it's a long time ... "Marina replied:" No. It is not the beer, we can not risk reputation. What to do? We are waiting for 21 days. " Proven sources say that in the summer of Zhiguli, however, it was very difficult to find in stores. Frequently asked questions about the addition of alcohol in the beer, because see barrels with an alcohol in the factory. But the alcohol in beer is added. The process of beer production requires an infinite sampling for samples and analyzes. Samples were taken through special air valves. But the process of production requires sterility. Therefore, after each sample air valves are filled with alcohol for disinfection. Cock very much, so alcohol is also very much necessary.

Rove beer in a tall, narrow tanks. The contents of one container in a diffuse and takes a packed train.

17. Next, the beer is sent to the filter. Unfiltered varieties respectively this stage do not pass. Yeast've already taken. During filtering the yeast from the beer finally removed, it becomes completely transparent.

18. We are almost swallowed foam, and we went on))

19. Many people ask about the unusual lighting in the shop filtration. No cunning plan - it just happened.

Another interesting point. Beer does not like oxygen, which is why for a long time an open beer becomes tasteless. Therefore, in the production process of oxygen ingress into beer suppressed. Oxygen is allowed once - in the wort with the addition of yeast to start the fermentation process. The shop is installing filtration dezaeratsii, which finally removes ksilorod caught in a drink at this stage of production.

20.

21. In the preparation of non-alcoholic beer is added another stage. Beer prepared, as usual, but in the finale of it evaporated alcohol.

Interestingly, if something went wrong, before filtering the beer can still be saved. After - already do. In this case, the spoiled beer poured down the drain. At the factory of the IPC it happened one time. The staff looked sadly at how cars merge into drains beer. According to rumors, it is not received at the plant, this time around Mytishchi almost every corner you can find natural point at which sold for mere pennies "beer just from the factory." Well, still live in Russia) Everything good can not disappear.

The finished beer is not added preservatives. Bottom-fermented beer itself is stored for a long time. To beer kept even longer, it is in the process of pasteurization: Very warm, aged about a minute, and then rapidly cooled. It does not live beer is pasteurized, so it tastes better, but few stores. Pasteurization occurs in the bottling hall. Here the beer is bottled (glass and plastic), banks and kegs.

22. IPC only uses the new packaging. They already have the equipment to use returnable containers. But the use of returnable containers costing the company more expensive than the use of a new one. Therefore, this equipment will be used only if the authorities at the legislative level, the company will be obliged to use the back container. Despite the fact that the packaging and checked for the new glass factory, where it is checked again. After all, even hairline cracks can occur during transport. A microcrack may affect the quality of the beer. When we have a special one flaw I discarded the bottle.

23. This central laboratory. Here, check the quality of the components and the finished beer.

24. This pipe bridge between different plant production:

25. The plant makes a very good impression. Everywhere beautiful, clean, everything shines. The staff at the production of the minimum - everything is automated as much as possible.

Looking at the production process, we go to evaluate the result at the tasting bar in the canteen.

26. This cozy.

27. We tried Zhiguli Barney Redhead villager) Unfortunately, was not connected with the keg Brezhnyakom. If there was Brezhnyak, we would have been able to try cutting beer. Cutting the beer - it's different kinds of beer, bloodshot layers due to the difference in density, and the skill of the bartender. When you drink, of course, the layers were mixed, giving unusual flavors, but first cutting the beer probably looks beautiful and unusual.

28. Lada Bar all liked Ginger villager. It is simply more familiar, beer, with characteristic bitterness. But Selyanka mood is also good. Sometimes I feel like such a gentle taste without bitterness. By the way, no matter how bitter or had a beer in their recipes and varieties, the bitterness should not dwell on the throat for more than 10 seconds. If a minute passed, and you still bitter - beer is something wrong.

Real men drink beer to sip 3, no matter how much it was poured)) First half drink in one gulp, then half of the half, and then the rest. They say that a good beer after every pull on the cup remains a foam ring.

From left villager. In Zhiguli not had time to focus. The partners say, too, were following.

29. In addition the foam should not sag uniformly and must like tufts. If you want to enjoy the taste of beer, it is not a snack roach, salty crackers and chips - a snack crumbs of white bread and simple dryers without additives. To compare a few beers, breaks gnaw the same drying and crackers. Professional tasters try the beer warm - torlko so can reveal all of his faults. But to drink beer in the fun it is imperative chilled to 12 degrees. We were shown "female" American beer Coors Light, it is recommended to be cooled to 8 degrees (the white mountains on the label turn blue). Interestingly, if the beer was heated and then cooled, the taste has changed irrevocably. It is therefore important to store beer. Beer does not tolerate vanity and drinking on the run. Drink beer need to slowly, in good company. Beer does not like dirty dishes. Especially not like fat. Even when you eat chips and greasy lips leans against the glass, beer taste spoiled. The beer is better to drink fresh. This is not a wine that time only benefit. Beer is like a man - it is aging. Beer does not like oxygen. If the beer is in the air for a long time, it spoils. So do not rush when drinking, but do not tighten hard. Fortress not depend on the color of beer. Dark beer is not stronger light. Strength depends on the recipe and the desire of the brewer. Dark beer, however, is often stronger than the light, but not because of the characteristics of malt. By the way, Brezhnyak light at 0, 3% stronger Brezhnyaka dark. beer in kegs kept longer because kegs have double walls, in fact it's a thermos. In the case of reverse kegami packaging used. Beer in cans and bottles should be the same taste. Bank should not give a metallic taste.

Source:

Tags

See also

How do bayans

Ten of the world's most expensive Beers

How do supercar Marussia (41 photos)

As I drank beer

How do pencils

How do prizes for strokes

How do Bushmills whiskey

How do the rubble

How to make Christmas decorations (10 photos)

How do the tube.