LiAZ - Likino Bus Plant

Bashny.Net

Bashny.Net

69 Photo © dalnoboi-russia

We present our pictures from the Likino Bus Plant. Nestle, the photos will be many.

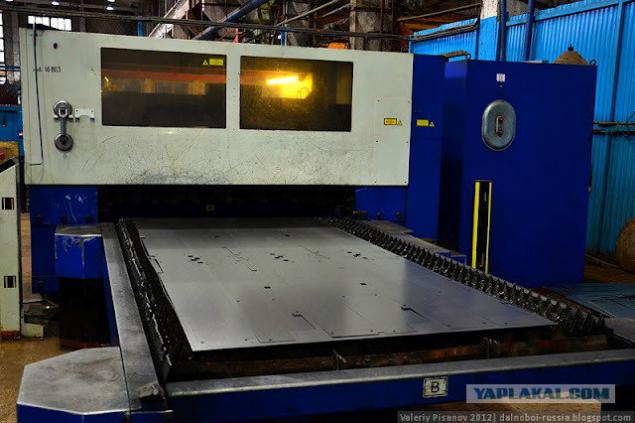

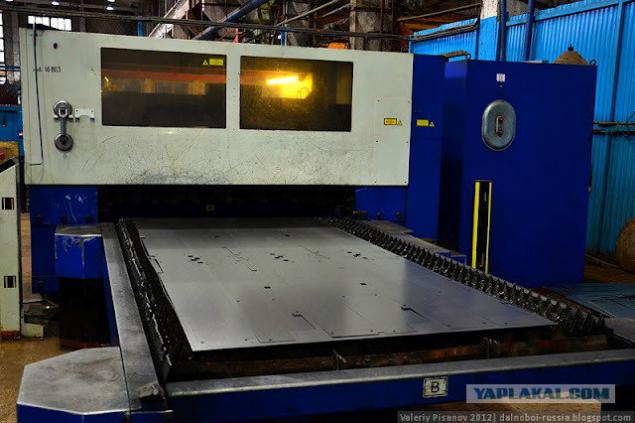

1. Our tour of the factory begins with pressing and blanking shop.

2. Here comes the longitudinal and transverse cutting of rolled steel, as well as all the necessary blanks for cold forming parts of future coaches.

3. Line "Halbron."

4. The production of cold-stamping body panels are made facing, as well as parts and components of the elements of the body shell.

5. Plot laser cutting using a set of «Trumpf TL - 3030".

6. Use cunning crane operator submits a metal sheet in the working area of the machine.

7. We were able to look behind the shield and the spy, like a laser beam at high speed burns right profile for future harvesting.

8. After a while, the machine unloads finished parts.

9. But this is only the beginning of a long process.

10. A little later, with the help of the press, they will give the desired shape

11. Finished parts waiting to be the next stage of production.

12. Workflow.

13. Manufacture, coil - evaporator air system. Later, we see the item appears on the finished bus.

14. Now the tour proceeds to the shop welding and bodywork production. The photo - assembly line welding roof SCHLATTER. Pre-operating gain on the stock elements of the future roof.

15. SCHLATTER at work.

16. Follow the assembly line on a thread and we will. Step by step, the elements of the bus are becoming more and more details.

17. The front panel of the bus going. Welder at work.

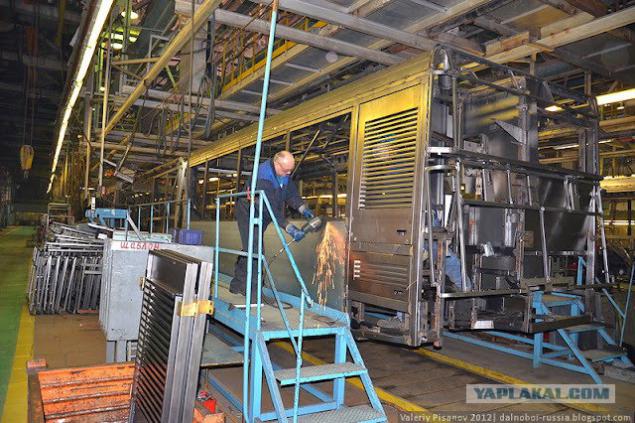

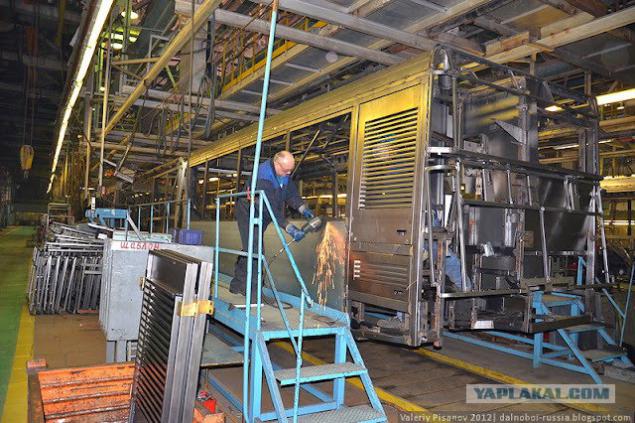

18. Finally, it is time when the conveyor is collected in a single unit all the elements of the frame of the bus. Front - in the photograph.

19. The so-called frame - the lower bearing part of the body of the bus.

20. stocks under strict geometry of the body, all the parts are assembled into a single unit

21. Operator.

22. Welding of the body on the stocks. Now, if you wish, you can see the silhouette of the future bus.

23. Next, on the line, ready to frame sheathe sheets of metal.

24. In order to board the bus were absolutely smooth on lyase used a unique technology. Before welding, the metal sheet is heated to a temperature of 90 degrees Celsius. It increases in size, and only then, pull it to the frame.

25. The final touches of body production.

26. Notice the two parts, articulated bus arrive at the body cataphoretic treatment.

27. Analogues such a process for the body of this size in Russia, other CIS countries and CIS countries there

28. The process command fragile girl.

29. Body alternately dipped in several large baths.

30. At the time, the plant became the first company in Russia by applying the full body anti-corrosion treatment by cataphoresis. In this method of electrolytic coloring it is that the product is placed in a cataphoresis bath, exposed to an electric field. As a result, a special water-based paint is deposited on all the product as a whole, not missing even the hard parts. Clutch epoxy layer with the metal is extremely durable, and the resulting coating is resistant to the most aggressive weather conditions.

30. At the time, the plant became the first company in Russia by applying the full body anti-corrosion treatment by cataphoresis. In this method of electrolytic coloring it is that the product is placed in a cataphoresis bath, exposed to an electric field. As a result, a special water-based paint is deposited on all the product as a whole, not missing even the hard parts. Clutch epoxy layer with the metal is extremely durable, and the resulting coating is resistant to the most aggressive weather conditions.

32. For me it was a revelation that the roof of the bus, one hundred percent covered by a plastic sheet.

33. lyase argue that this technology on the order of practical and durable.

34. The company constantly employs about one and a half thousand workers at an average salary of 35 thousand rubles.

35. At this point, in February 2012, each shift of the gate of the plant beyond 10 brand new buses.

36. But the shaft on orders for lyase occurs at the end of the year, as The main customers of the enterprise budget organizations. At such times, the output bus assembly line increases sharply. The company is gaining temporary workers and raise wages.

37. The bodies are the subject of legitimate pride of the plant.

38. LiAZ ensures that the body of its buses will serve at least 12 years before rust.

39. Share your smile!

40. The final stage before sending the body color.

41. Friendship.

42. painted floats.

43. It is time to get down to business masters window Affairs.

44. Clamps.

45. To say that the work is literally burning in the hands of masters, will not be enough - it must be seen with my own eyes.

46. The size of the company is impressive. The branch pipeline floats on two floors simultaneously

47. It is time to get down to the final assembly line of buses. Every 45 minutes on a conveyor mounted axles, every 90 engine.

48. On request, the machine equipped with bridges of firm ZF, Raba or domestic KAAZ.

49. In this case, as seen in the photo, the bus set Drive German manufacturer - the company ZF.

50. The choice of engine and gearbox also depends on the willingness of the customer. Gamma units wide, from domestic YaMZ and KAMAZ, to the best samples of imported companies MAN, Caterpillar, Cummins. Transmission Voith, ZF.

52. Next comes the least interesting thing docking of two halves articulated bus.

53. As you know, LiAZ one of the first factories who started manufacturing buses in Russia similar design.

54. It was the beginning of serial production of the bus LIAZ-6212, with our streets began to disappear Hungarian "bunching" of Icarus.

55. Hydraulic cylinders in the node junction equipped with electronic brains, and now to prevent a skid trailer and hard blows in extreme positions, the cylinders vary the degree of damping, depending on the angular velocity of rotation.

56. lyase applied new scheme - the driving wheels on articulated buses are in the trailer. It was he who pushes the bus. Therefore, when the danger of folding on a slippery surface, the cylinders are locked mechanism.

57. The mechanism of articulation is about 1 million. Rubles. Of these, the mechanism 700 thousand. And 300 thousand more. So-called "accordion".

58. Doors ordinary.

59.I God forbid, "just fire».

60. Major customers LiAZ large motor transport in cities.

61. A series of buses with yellow - orange color is for the new program of the Government of Moscow. Bright buses will run on dedicated lanes for public transport.

62.

63. Debugging and testing electronics.

64. Filling buses technical liquids. In this case, in the air conditioning system refrigerant charge bus

65. The driver of the bus. In my opinion, everything is on the level.

66. I remove the newcomer to become the first passenger of the bus. Do not be surprised the lack of seats in the cabin. Such an order Mosgortrans apparently lifetime seat longer than the service life of the bus.

67. Before leaving the factory gets on the bus line independent control. This is a special technique of audit of the car «CSA», made on the basis of international standards, its goal is to give an independent assessment of the quality of the car "positions

68. Only later, the bus will travel to the consumer, and its passengers.

69 ... For the organization and conduct of tours, thank plant manager LiAZ Kazakov Alexander, as well as Director of the Department of Mass Communications LLC "Russian Buses - GAZ Group" Voronina Ella Alexandrovna, and personally PR manager Olga A. Fefelova.

Posted in [mergetime] 1328513105 [/ mergetime]

Hence sdelanounas.ru/blogs/13510/#cut

Source:

We present our pictures from the Likino Bus Plant. Nestle, the photos will be many.

1. Our tour of the factory begins with pressing and blanking shop.

2. Here comes the longitudinal and transverse cutting of rolled steel, as well as all the necessary blanks for cold forming parts of future coaches.

3. Line "Halbron."

4. The production of cold-stamping body panels are made facing, as well as parts and components of the elements of the body shell.

5. Plot laser cutting using a set of «Trumpf TL - 3030".

6. Use cunning crane operator submits a metal sheet in the working area of the machine.

7. We were able to look behind the shield and the spy, like a laser beam at high speed burns right profile for future harvesting.

8. After a while, the machine unloads finished parts.

9. But this is only the beginning of a long process.

10. A little later, with the help of the press, they will give the desired shape

11. Finished parts waiting to be the next stage of production.

12. Workflow.

13. Manufacture, coil - evaporator air system. Later, we see the item appears on the finished bus.

14. Now the tour proceeds to the shop welding and bodywork production. The photo - assembly line welding roof SCHLATTER. Pre-operating gain on the stock elements of the future roof.

15. SCHLATTER at work.

16. Follow the assembly line on a thread and we will. Step by step, the elements of the bus are becoming more and more details.

17. The front panel of the bus going. Welder at work.

18. Finally, it is time when the conveyor is collected in a single unit all the elements of the frame of the bus. Front - in the photograph.

19. The so-called frame - the lower bearing part of the body of the bus.

20. stocks under strict geometry of the body, all the parts are assembled into a single unit

21. Operator.

22. Welding of the body on the stocks. Now, if you wish, you can see the silhouette of the future bus.

23. Next, on the line, ready to frame sheathe sheets of metal.

24. In order to board the bus were absolutely smooth on lyase used a unique technology. Before welding, the metal sheet is heated to a temperature of 90 degrees Celsius. It increases in size, and only then, pull it to the frame.

25. The final touches of body production.

26. Notice the two parts, articulated bus arrive at the body cataphoretic treatment.

27. Analogues such a process for the body of this size in Russia, other CIS countries and CIS countries there

28. The process command fragile girl.

29. Body alternately dipped in several large baths.

30. At the time, the plant became the first company in Russia by applying the full body anti-corrosion treatment by cataphoresis. In this method of electrolytic coloring it is that the product is placed in a cataphoresis bath, exposed to an electric field. As a result, a special water-based paint is deposited on all the product as a whole, not missing even the hard parts. Clutch epoxy layer with the metal is extremely durable, and the resulting coating is resistant to the most aggressive weather conditions.

30. At the time, the plant became the first company in Russia by applying the full body anti-corrosion treatment by cataphoresis. In this method of electrolytic coloring it is that the product is placed in a cataphoresis bath, exposed to an electric field. As a result, a special water-based paint is deposited on all the product as a whole, not missing even the hard parts. Clutch epoxy layer with the metal is extremely durable, and the resulting coating is resistant to the most aggressive weather conditions.

32. For me it was a revelation that the roof of the bus, one hundred percent covered by a plastic sheet.

33. lyase argue that this technology on the order of practical and durable.

34. The company constantly employs about one and a half thousand workers at an average salary of 35 thousand rubles.

35. At this point, in February 2012, each shift of the gate of the plant beyond 10 brand new buses.

36. But the shaft on orders for lyase occurs at the end of the year, as The main customers of the enterprise budget organizations. At such times, the output bus assembly line increases sharply. The company is gaining temporary workers and raise wages.

37. The bodies are the subject of legitimate pride of the plant.

38. LiAZ ensures that the body of its buses will serve at least 12 years before rust.

39. Share your smile!

40. The final stage before sending the body color.

41. Friendship.

42. painted floats.

43. It is time to get down to business masters window Affairs.

44. Clamps.

45. To say that the work is literally burning in the hands of masters, will not be enough - it must be seen with my own eyes.

46. The size of the company is impressive. The branch pipeline floats on two floors simultaneously

47. It is time to get down to the final assembly line of buses. Every 45 minutes on a conveyor mounted axles, every 90 engine.

48. On request, the machine equipped with bridges of firm ZF, Raba or domestic KAAZ.

49. In this case, as seen in the photo, the bus set Drive German manufacturer - the company ZF.

50. The choice of engine and gearbox also depends on the willingness of the customer. Gamma units wide, from domestic YaMZ and KAMAZ, to the best samples of imported companies MAN, Caterpillar, Cummins. Transmission Voith, ZF.

52. Next comes the least interesting thing docking of two halves articulated bus.

53. As you know, LiAZ one of the first factories who started manufacturing buses in Russia similar design.

54. It was the beginning of serial production of the bus LIAZ-6212, with our streets began to disappear Hungarian "bunching" of Icarus.

55. Hydraulic cylinders in the node junction equipped with electronic brains, and now to prevent a skid trailer and hard blows in extreme positions, the cylinders vary the degree of damping, depending on the angular velocity of rotation.

56. lyase applied new scheme - the driving wheels on articulated buses are in the trailer. It was he who pushes the bus. Therefore, when the danger of folding on a slippery surface, the cylinders are locked mechanism.

57. The mechanism of articulation is about 1 million. Rubles. Of these, the mechanism 700 thousand. And 300 thousand more. So-called "accordion".

58. Doors ordinary.

59.I God forbid, "just fire».

60. Major customers LiAZ large motor transport in cities.

61. A series of buses with yellow - orange color is for the new program of the Government of Moscow. Bright buses will run on dedicated lanes for public transport.

62.

63. Debugging and testing electronics.

64. Filling buses technical liquids. In this case, in the air conditioning system refrigerant charge bus

65. The driver of the bus. In my opinion, everything is on the level.

66. I remove the newcomer to become the first passenger of the bus. Do not be surprised the lack of seats in the cabin. Such an order Mosgortrans apparently lifetime seat longer than the service life of the bus.

67. Before leaving the factory gets on the bus line independent control. This is a special technique of audit of the car «CSA», made on the basis of international standards, its goal is to give an independent assessment of the quality of the car "positions

68. Only later, the bus will travel to the consumer, and its passengers.

69 ... For the organization and conduct of tours, thank plant manager LiAZ Kazakov Alexander, as well as Director of the Department of Mass Communications LLC "Russian Buses - GAZ Group" Voronina Ella Alexandrovna, and personally PR manager Olga A. Fefelova.

Posted in [mergetime] 1328513105 [/ mergetime]

Hence sdelanounas.ru/blogs/13510/#cut

Source:

Tags

See also

Soviet cyber-vintage

Inheritance grandchildren

Chelyabinsk-Baikal 2011

"Travel" - a competition in 2014 by National Geographic

daughter Education - what is important to remember

To take away the trash

Where does the trash

Where does the garbage ...

Backstage Russia Today