Production of fresh beer

Bashny.Net

Bashny.Net

I propose to go to the brewery and see the process of making a living beer.

The photo shows the plant, a large part of it is occupied by the tanks in which the beer matures and ripens.

Author:

Rule one, "Without shoe covers in the shop did not go!" Let's not broken, the more it is not necessary to persist and laugh all the surrounding process napyalivaniya them on shoes, but simply and elegantly trust in to this miraculous machine, puts the marked shoe covers you on your feet.

Everyone knows that the theater begins with a hanger, and the brewery starts with malt. Here he is in stock in bags, packaged in a standard 50 kg. This plant is used only natural malt.

And so, for reference only say that in addition to malt for beer production need hops, special brewer's yeast, and of course water, without in any way here. Water the plant comes from artesian wells. And for thousands of liters of beer, you will need 1100 liters of water.

For those who do not know, malt - the product obtained in the germination of seeds of cereals, mainly barley. During the germination of seeds it produced the desired brewers enzymes. Here he kartinochku.

But malt as such can not be run in production, in order to begin the process of brewing beer, malt need to prepare - it must be crushed. Here in the mill (solododrobilke).

Milled malt must not be uniform. Malt to include both small and coarse grains and also fine flour. At the same time cereal spine should remain almost intact. For the cooking of different types of beer you need a different ratio of small and large particles in the crushed product. Here you have a bag of milled malt.

During the cooking process should be crushing. That begins with the fact that the crushed malt and water are mixed in a mash-brew kettle. This renewed activity of enzymes, pause after drying malt. Revived enzymes begin to convert starch from which 70% of the grain and malt sugar. To accelerate the process of fermentation cereal malt (mash) is gradually heated to a temperature of saccharification - 76 ° C. As a result, almost all of the remaining starch is split into sugar and dextrins which during mashing to dissolve in water.

Before you brewhouse. Where is actually going on the whole process of cooking.

The cooking process is quite complex and multi-stage, taking into account a number of factors. Main phase I will now sign for, if only to ensure that you are raising a glass of this drink, understand those transformations and the volume of work of many people that expended in order to enable you to relax and unwind. Those who do not like to read mnogabukaff, you can scroll on and enjoy the pictures.

Thus, the boiler is filled with hot water, then pre-ground malt, the mixture is maintained at a temperature just above 50 ° C for 20 minutes with constant stirring. This process is called "phase protein." When the temperature reaches 64 ° C weight, leaving a mass of "rest" for 60 minutes. It is necessary to pay attention to the temperature of the mass. Permissible temperature fluctuation of plus or minus 2 ° C. During those 60 minutes there saharizatsiya wort. The mass was then further heated to a higher temperature, and begin to be pumped into the filter tank. Then the wort goes through several stages of filtration, and finally returns to the mash-brew kettle.

The digester is heated and wort boiling. At this stage in the future beer hops are added. The dose depends on many conditions: the variety and quality of the hops on the properties of water and beers, which are going to cook. It takes a responsible decision brewer, based on their experience and intuition, for example, the Dortmund export is usually taken twice less hops than pilsner, but the exact amount every time defines the master.

Cooking basic wort lasts a half to three hours. Under the influence of prolonged heating of the mash all microorganisms are killed and destroyed natural enzymes, so the composition of the wort does not occur any chemical changes. Contained in hop lupulin partially dissolved in the wort, connecting with its components and giving the characteristic bitterness of the beer.

Hops gives beer wort particular bitterness and fills its own flavor. And hop bitter acids contribute to impeding the coagulation of protein compounds. This is called coagulate - Bruch. From the fullness of coagulation protein compounds depend on taste, transparency, head retention and stability of the finished beer.

Then, the liquid is pumped into the beer fermentation tank. But so hot it is impossible to apply. The hot liquid from a beer wort boiler is pumped through the coarse and fine filtration of a heat exchanger, where the beer is cooled to a liquid temperature of 12 ° C and the heat exchanger into the tank fermentation.

In the process of filling the tank of fermentation liquid are mixed in beer yeast.

Now let's move to the next room - the fermentation plant. There is a light, warm and very clean. Rovnenko rows, as a ruler, are fermentation tanks.

Each tank has its own number. Red numbers marked fermentation tanks. Blue - tanks ripening.

After filling the tank with liquid fermentation of beer yeast and giving begins the fermentation process lasting 6-8 days. Approximately after days after laying on the surface of yeast mash formed thick yellowish-white foam. This indicates that yeast have already started their vital functions, in which maltose is converted into alcohol and carbon dioxide. The degree of fermentation of beer is determined saccharometer.

During the fermentation cycle, the formation of alcohol. Every 24 hours, the level of control the degree Balling. All parameters recorded on such leaflets that hang on each tank.

For the fermentation process requires maintaining the temperature within a certain range, it fermentation tank maintained at 11-13 ° C (depending on the type of beer). For automatic temperature control monitors.

When degrees Balling reach the desired values, the tank is hermetically closed, and it reached saturation beer liquid carbon dioxide of natural origin, the pressure in the tank can be monitored by pressure gauges like this. All tanks are equipped with pressure regulators, their job is to maintain the reservoir slight overpressure.

After the end of fermentation, fermented beer is pumped into the tanks maturation. The temperature of the liquid beer is kept at 6 ° C. At this temperature the yeast is trapped in the tank ripening contribute to the normal flow of the process of ripening or so-called fermentation (fermentation quiet). In the process of ripening naturally produces carbon dioxide (C02) and the beer is saturated with carbon dioxide of natural origin. At this stage, the beer becomes characteristic of the class features within 13-14 days.

Tanks, top view.

Please note that tanks are not entangled in all kinds of pipelines pumping / transfer and so on. Let me explain why. The fact is that beer, like any other food liquids sufficiently aggressive to metals, therefore, over time, all lines covered areas micropitting and microcracks, which is very good life every microorganisms. And besides all these intertwining pipes require periodic flushing that costly, both in money and in time.

What then is pumped beer from these tanks? And that's what - that's this rubber sleeve, it is specifically designed for food liquids.

After the beer is matured, it is cooled to a temperature of from 0 ° C to + 2 ° C. And waiting in the wings drink bottling.

After the process of maturation necessary to carry out its filtering (this is if we want to get filtered beer). What is being done? Filtered beers that's this beautiful unit.

Because of this valve, that at the top of the filter, the beer comes out clean and transparent crystal. I think many people would not refuse such a cock with beer at home

Beer goes, it can be seen through the transparent window in the tap.

And so, just a fragment of the filter. And try to say that there is no uniformity of beauty.

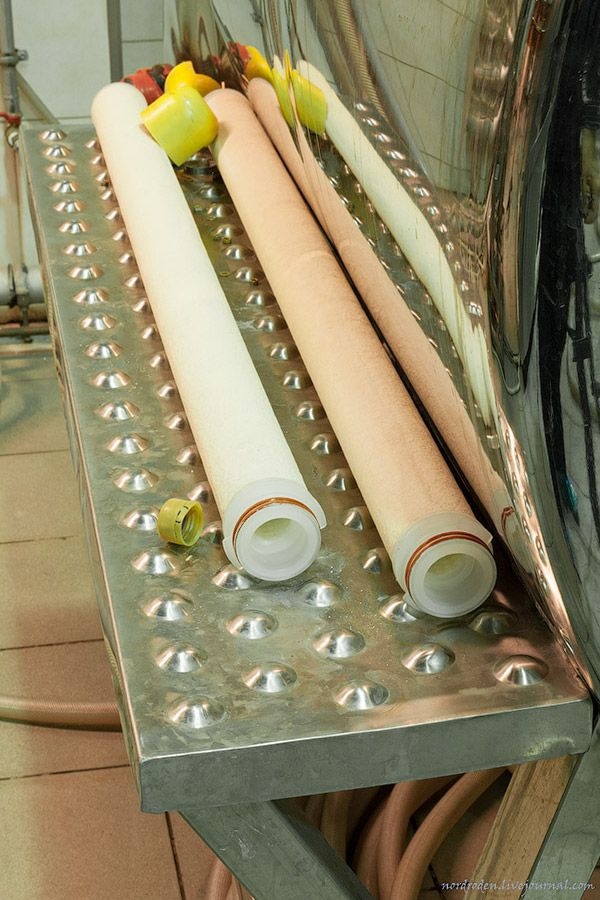

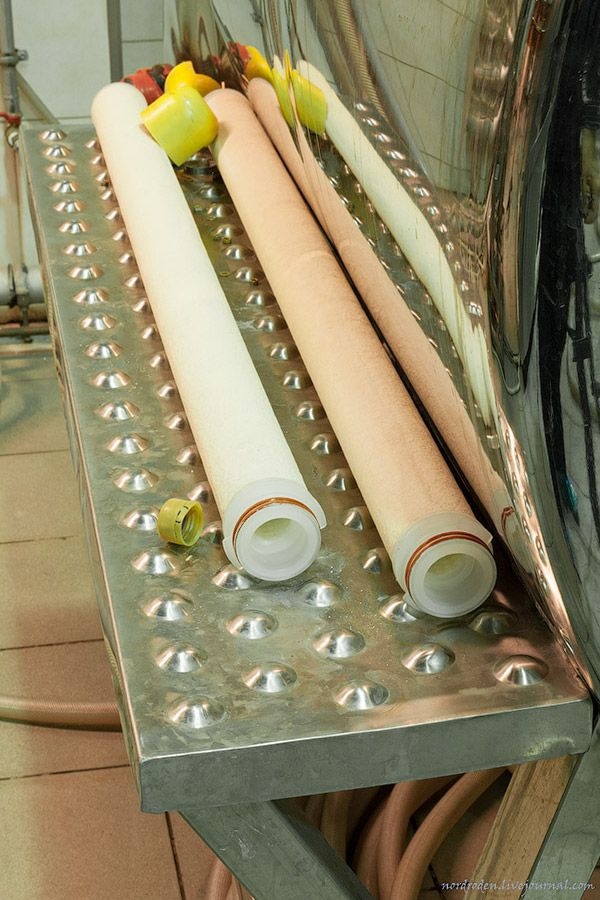

Oh, I almost forgot, that's placed inside the filter, such filter elements. Before the work of their specially prepared by multiple-coating filter layer consisting of crushed limestone dust, which is produced only four places on the planet. Of course, before you have spent your filter elements.

And now come out of the shop, which serves beer and look at the shop where the injection molding machine. What for? And then, without further production of this beer production plant is difficult, unless you pour it in barrels. This workshop produces blank (preform) for plastic bottles, which are then poured into the beer.

The whole process of manufacturing a preform begins here with these plastic pellets. Plastic is tricky name - polyethylene terephthalate (PET).

The beads are brought here in such large bags, colloquially called big-bag.

The pellets are sucked out of the bag and ...

... And enter the drier where they are dried for 6 hours.

Then pellets fall into the injection molding machine

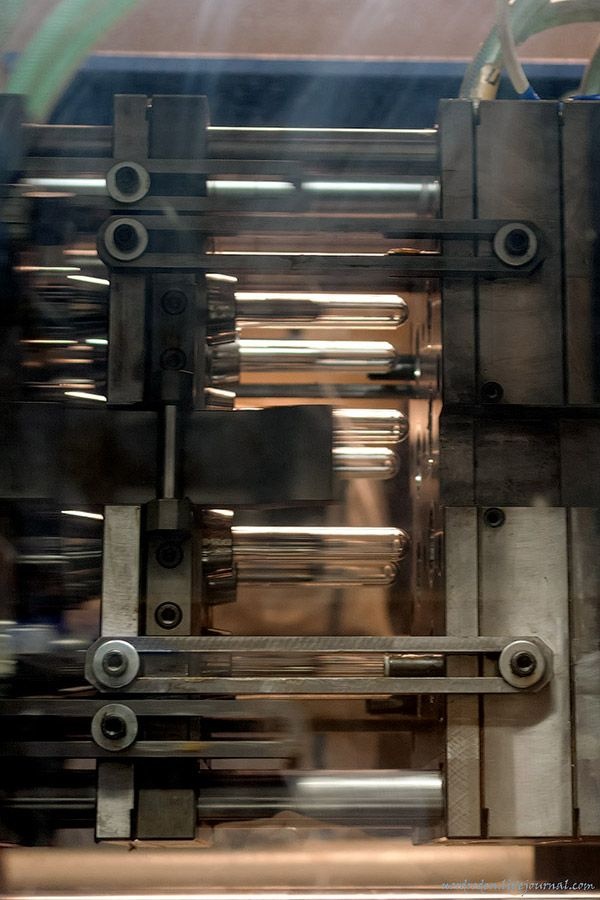

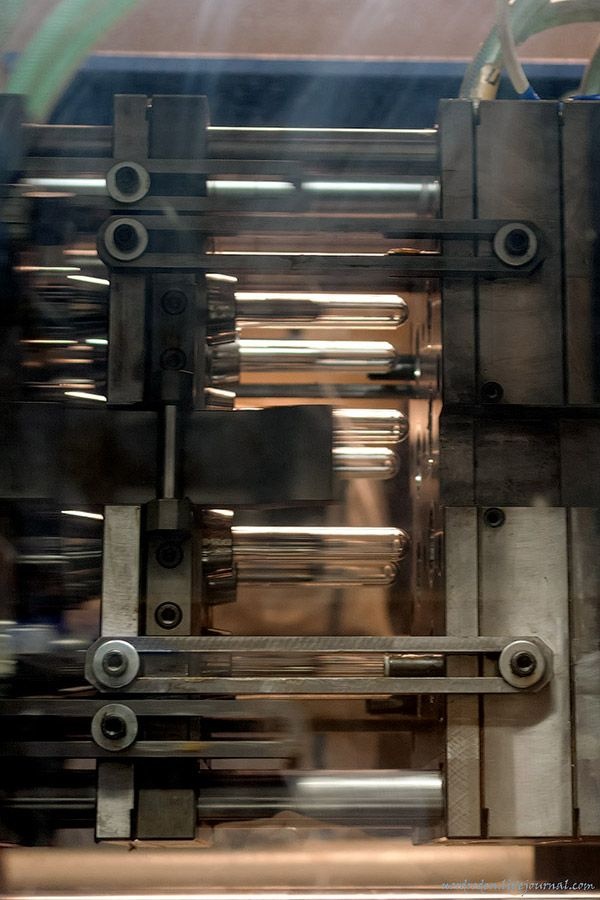

Preforms produced by injection molding. Attachments - hot runner molds. Attachments - Multi.

Plastic preforms are ready.

What next? As beer storage tanks gets into the bottle? We now turn to the filling station.

Again picture preforms, once they are already in another shop and a few minutes turned into a bottle.

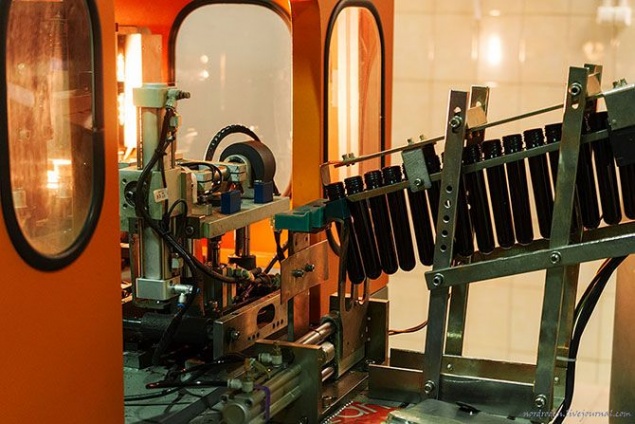

The preforms are placed in the receiving hopper sorting machine. Use the scraper conveyor, they are served in the finisher.

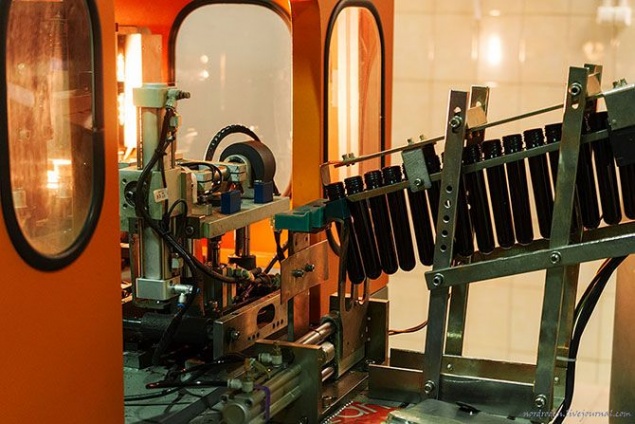

Here he is. In this block blank sorted and installed in the transfer belt, consists of a pair of metal rails.

So here's how to gorochki, bars move out to the receiving node blowing machine.

Preparations using paddle flipped and dress up for these brackets. Which form a conveyor.

To this we can watch endlessly ... I hovered for a few minutes, watching the process.

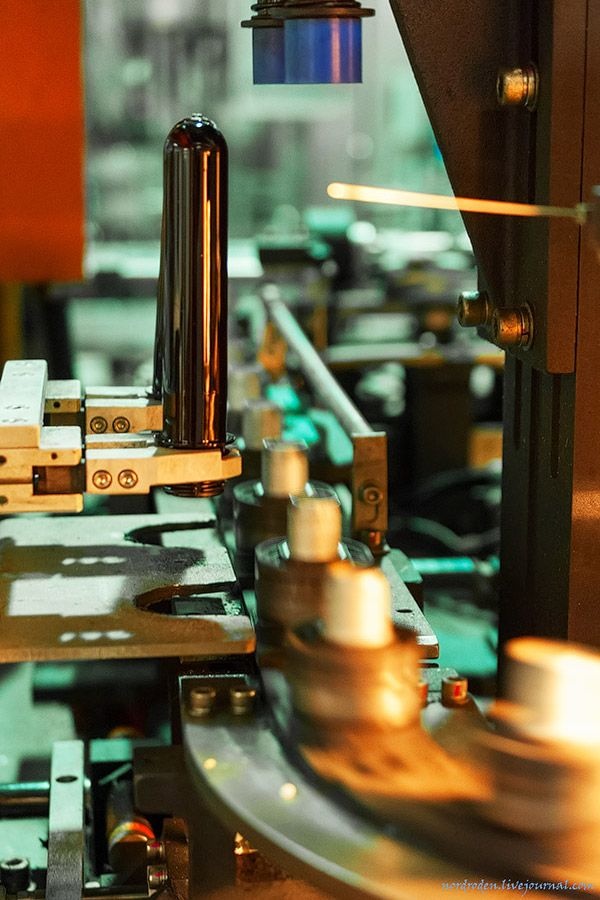

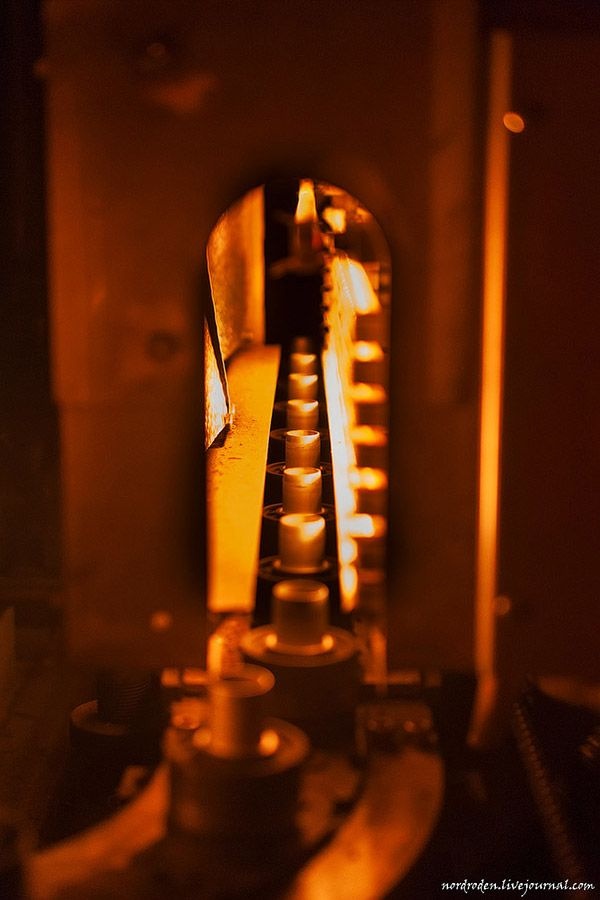

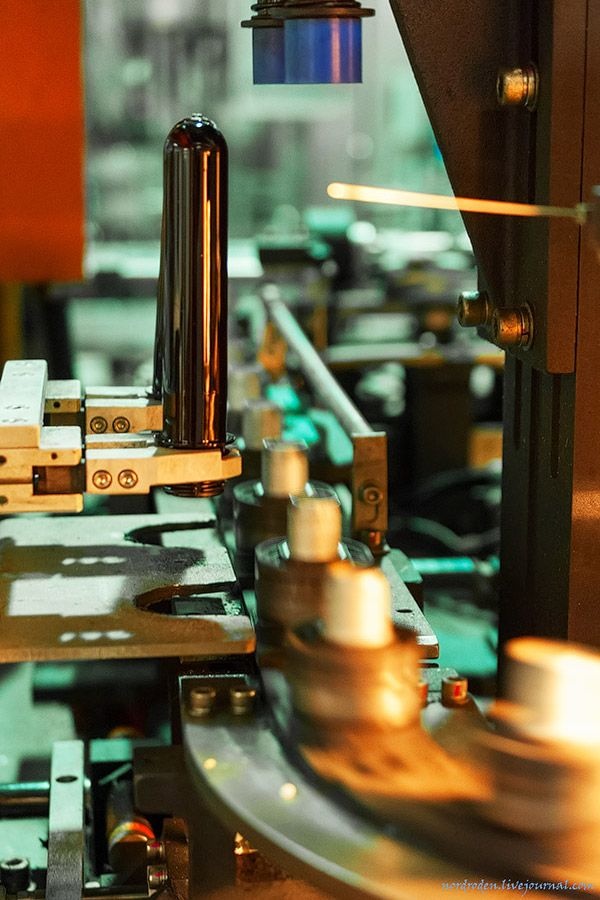

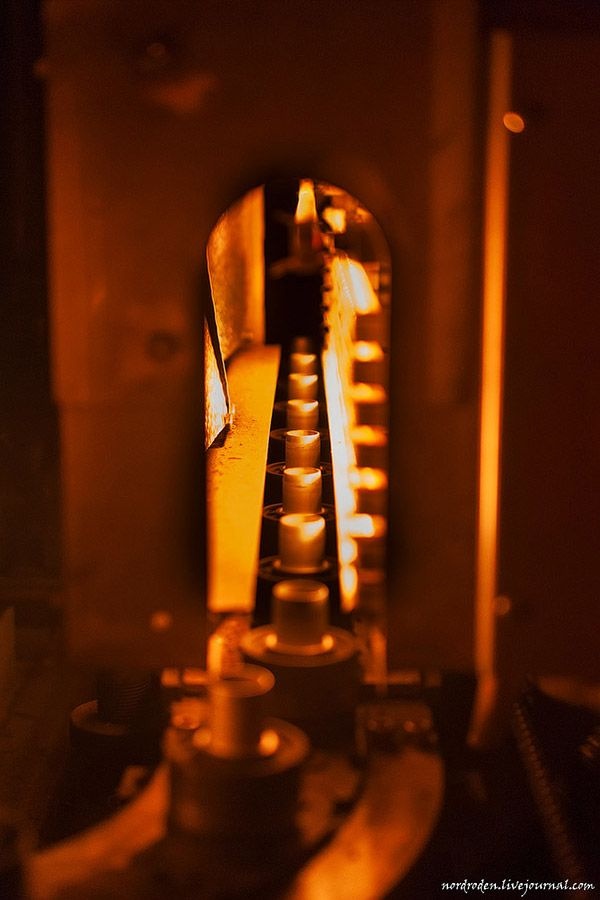

To machine could blow plastic bottle, it is necessary to heat up the plastic, so the workpiece is mounted onto the bracket and slowly moves in the heating unit.

Here's how the node looks like when there's nothing there.

Preparations for the time spent in this on-the-very warm place time to warm up to the desired temperature and, accordingly, to soften.

To improve the efficiency of the plant heaters have a fan, you hot? And what these preforms?

I walk around the machine with the other hand to show you how to make a bottle.

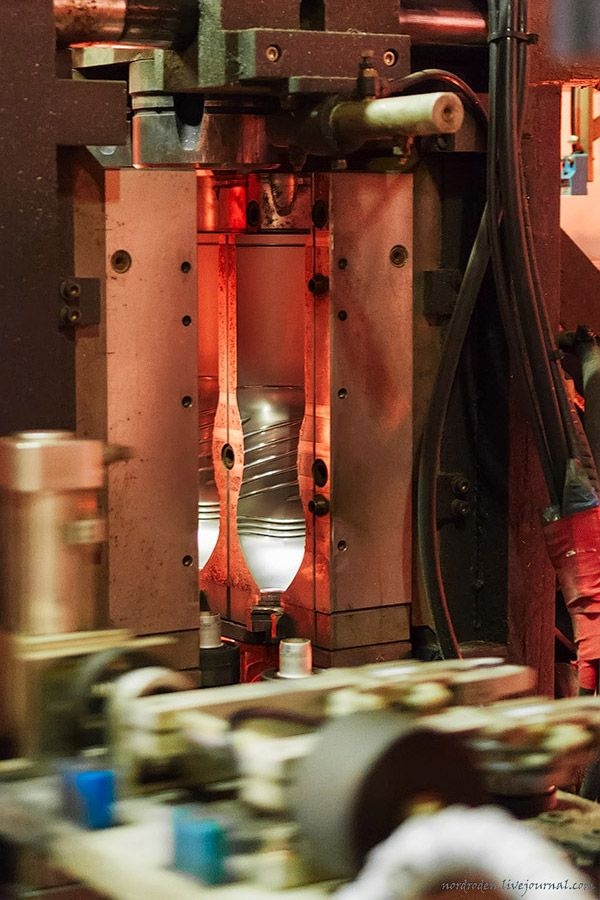

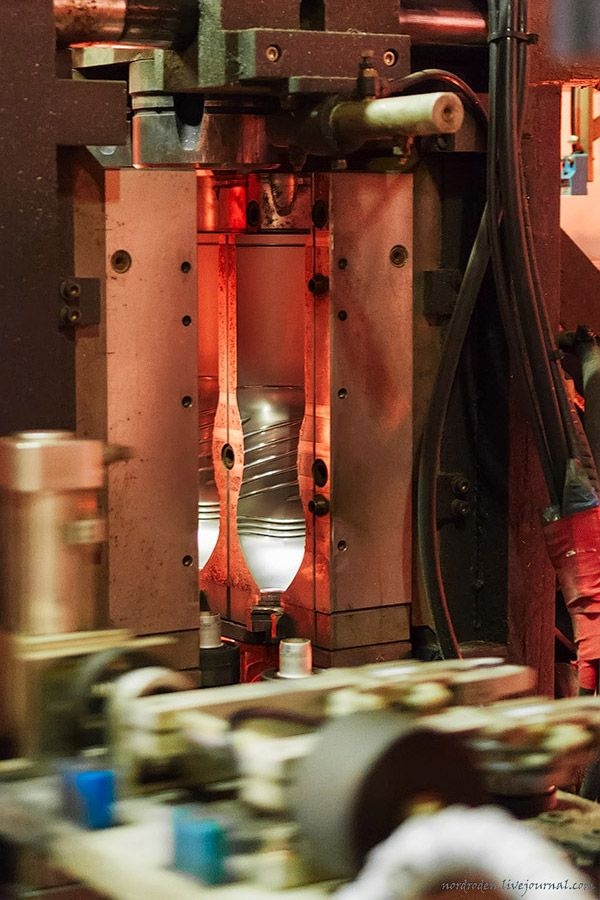

After harvesting hot, it gets between the halves here this mold. The halves are closed tightly and the inner cavity of the workpiece is supplied with compressed air. The blank is inflated like a balloon, taking all the contours of the mold.

And at the exit already have the finished product.

What's next? Then the brand new bottle lining up on such overhead conveyor. The conveyor air is blown from the inside, it is done for two reasons, the first - for the cooling of bottles, the second - to prevent the ingress of particles inside the bottle in the air. Purging is carried out with three fans, they are clearly visible in the frame. At the entrance there are fans air filters.

Now, after a short wait, the bottles fall into the dispenser

Although the bottle and clean, but still the first thing - washing. With a bottle conveyor fall into the clutches this octopus. It looks like a fragment wash carousel.

That's a general view of this part of the machine

Bottle washed and ready to take a drink.

The bottle is then transferred to a section where it will be filled with beer and bottled up. Transparent doors opened at our request, in order that we can properly remove the mechanisms of this machine. When we made our photographic business, closed the door immediately - cleanliness above all.

Carousel Carousel ... then poured a beer in a bottle ...

... And then the bottle is sealed.

We go further up the chain ...

After filling - automatic control.

This checks the absence of inclusions in the filled bottle.

The bottle is then passed into the hands of machine, which is glued label.

Then lean ryadochkom ...

... Fall to the packaging machine.

At the entrance to the car of the bottles formed packs of 6 pieces.

Then, six bottles wrapped film. And out in the hot part of the machine, where the film melts and gives a small shrinkage, allowing the bottle firmly fixed.

That's the finish. The finished pack will be charged to workers and stacked on pallets. And it is the only operation where human hands relate to production, everything, absolutely everything makes automation.

Beer stacked in pallets, which are then razvezut of trading networks.

Finally, a general view of almost the entire plant.

Source: kak-eto-sdelano.livejournal.com

The photo shows the plant, a large part of it is occupied by the tanks in which the beer matures and ripens.

Author:

Rule one, "Without shoe covers in the shop did not go!" Let's not broken, the more it is not necessary to persist and laugh all the surrounding process napyalivaniya them on shoes, but simply and elegantly trust in to this miraculous machine, puts the marked shoe covers you on your feet.

Everyone knows that the theater begins with a hanger, and the brewery starts with malt. Here he is in stock in bags, packaged in a standard 50 kg. This plant is used only natural malt.

And so, for reference only say that in addition to malt for beer production need hops, special brewer's yeast, and of course water, without in any way here. Water the plant comes from artesian wells. And for thousands of liters of beer, you will need 1100 liters of water.

For those who do not know, malt - the product obtained in the germination of seeds of cereals, mainly barley. During the germination of seeds it produced the desired brewers enzymes. Here he kartinochku.

But malt as such can not be run in production, in order to begin the process of brewing beer, malt need to prepare - it must be crushed. Here in the mill (solododrobilke).

Milled malt must not be uniform. Malt to include both small and coarse grains and also fine flour. At the same time cereal spine should remain almost intact. For the cooking of different types of beer you need a different ratio of small and large particles in the crushed product. Here you have a bag of milled malt.

During the cooking process should be crushing. That begins with the fact that the crushed malt and water are mixed in a mash-brew kettle. This renewed activity of enzymes, pause after drying malt. Revived enzymes begin to convert starch from which 70% of the grain and malt sugar. To accelerate the process of fermentation cereal malt (mash) is gradually heated to a temperature of saccharification - 76 ° C. As a result, almost all of the remaining starch is split into sugar and dextrins which during mashing to dissolve in water.

Before you brewhouse. Where is actually going on the whole process of cooking.

The cooking process is quite complex and multi-stage, taking into account a number of factors. Main phase I will now sign for, if only to ensure that you are raising a glass of this drink, understand those transformations and the volume of work of many people that expended in order to enable you to relax and unwind. Those who do not like to read mnogabukaff, you can scroll on and enjoy the pictures.

Thus, the boiler is filled with hot water, then pre-ground malt, the mixture is maintained at a temperature just above 50 ° C for 20 minutes with constant stirring. This process is called "phase protein." When the temperature reaches 64 ° C weight, leaving a mass of "rest" for 60 minutes. It is necessary to pay attention to the temperature of the mass. Permissible temperature fluctuation of plus or minus 2 ° C. During those 60 minutes there saharizatsiya wort. The mass was then further heated to a higher temperature, and begin to be pumped into the filter tank. Then the wort goes through several stages of filtration, and finally returns to the mash-brew kettle.

The digester is heated and wort boiling. At this stage in the future beer hops are added. The dose depends on many conditions: the variety and quality of the hops on the properties of water and beers, which are going to cook. It takes a responsible decision brewer, based on their experience and intuition, for example, the Dortmund export is usually taken twice less hops than pilsner, but the exact amount every time defines the master.

Cooking basic wort lasts a half to three hours. Under the influence of prolonged heating of the mash all microorganisms are killed and destroyed natural enzymes, so the composition of the wort does not occur any chemical changes. Contained in hop lupulin partially dissolved in the wort, connecting with its components and giving the characteristic bitterness of the beer.

Hops gives beer wort particular bitterness and fills its own flavor. And hop bitter acids contribute to impeding the coagulation of protein compounds. This is called coagulate - Bruch. From the fullness of coagulation protein compounds depend on taste, transparency, head retention and stability of the finished beer.

Then, the liquid is pumped into the beer fermentation tank. But so hot it is impossible to apply. The hot liquid from a beer wort boiler is pumped through the coarse and fine filtration of a heat exchanger, where the beer is cooled to a liquid temperature of 12 ° C and the heat exchanger into the tank fermentation.

In the process of filling the tank of fermentation liquid are mixed in beer yeast.

Now let's move to the next room - the fermentation plant. There is a light, warm and very clean. Rovnenko rows, as a ruler, are fermentation tanks.

Each tank has its own number. Red numbers marked fermentation tanks. Blue - tanks ripening.

After filling the tank with liquid fermentation of beer yeast and giving begins the fermentation process lasting 6-8 days. Approximately after days after laying on the surface of yeast mash formed thick yellowish-white foam. This indicates that yeast have already started their vital functions, in which maltose is converted into alcohol and carbon dioxide. The degree of fermentation of beer is determined saccharometer.

During the fermentation cycle, the formation of alcohol. Every 24 hours, the level of control the degree Balling. All parameters recorded on such leaflets that hang on each tank.

For the fermentation process requires maintaining the temperature within a certain range, it fermentation tank maintained at 11-13 ° C (depending on the type of beer). For automatic temperature control monitors.

When degrees Balling reach the desired values, the tank is hermetically closed, and it reached saturation beer liquid carbon dioxide of natural origin, the pressure in the tank can be monitored by pressure gauges like this. All tanks are equipped with pressure regulators, their job is to maintain the reservoir slight overpressure.

After the end of fermentation, fermented beer is pumped into the tanks maturation. The temperature of the liquid beer is kept at 6 ° C. At this temperature the yeast is trapped in the tank ripening contribute to the normal flow of the process of ripening or so-called fermentation (fermentation quiet). In the process of ripening naturally produces carbon dioxide (C02) and the beer is saturated with carbon dioxide of natural origin. At this stage, the beer becomes characteristic of the class features within 13-14 days.

Tanks, top view.

Please note that tanks are not entangled in all kinds of pipelines pumping / transfer and so on. Let me explain why. The fact is that beer, like any other food liquids sufficiently aggressive to metals, therefore, over time, all lines covered areas micropitting and microcracks, which is very good life every microorganisms. And besides all these intertwining pipes require periodic flushing that costly, both in money and in time.

What then is pumped beer from these tanks? And that's what - that's this rubber sleeve, it is specifically designed for food liquids.

After the beer is matured, it is cooled to a temperature of from 0 ° C to + 2 ° C. And waiting in the wings drink bottling.

After the process of maturation necessary to carry out its filtering (this is if we want to get filtered beer). What is being done? Filtered beers that's this beautiful unit.

Because of this valve, that at the top of the filter, the beer comes out clean and transparent crystal. I think many people would not refuse such a cock with beer at home

Beer goes, it can be seen through the transparent window in the tap.

And so, just a fragment of the filter. And try to say that there is no uniformity of beauty.

Oh, I almost forgot, that's placed inside the filter, such filter elements. Before the work of their specially prepared by multiple-coating filter layer consisting of crushed limestone dust, which is produced only four places on the planet. Of course, before you have spent your filter elements.

And now come out of the shop, which serves beer and look at the shop where the injection molding machine. What for? And then, without further production of this beer production plant is difficult, unless you pour it in barrels. This workshop produces blank (preform) for plastic bottles, which are then poured into the beer.

The whole process of manufacturing a preform begins here with these plastic pellets. Plastic is tricky name - polyethylene terephthalate (PET).

The beads are brought here in such large bags, colloquially called big-bag.

The pellets are sucked out of the bag and ...

... And enter the drier where they are dried for 6 hours.

Then pellets fall into the injection molding machine

Preforms produced by injection molding. Attachments - hot runner molds. Attachments - Multi.

Plastic preforms are ready.

What next? As beer storage tanks gets into the bottle? We now turn to the filling station.

Again picture preforms, once they are already in another shop and a few minutes turned into a bottle.

The preforms are placed in the receiving hopper sorting machine. Use the scraper conveyor, they are served in the finisher.

Here he is. In this block blank sorted and installed in the transfer belt, consists of a pair of metal rails.

So here's how to gorochki, bars move out to the receiving node blowing machine.

Preparations using paddle flipped and dress up for these brackets. Which form a conveyor.

To this we can watch endlessly ... I hovered for a few minutes, watching the process.

To machine could blow plastic bottle, it is necessary to heat up the plastic, so the workpiece is mounted onto the bracket and slowly moves in the heating unit.

Here's how the node looks like when there's nothing there.

Preparations for the time spent in this on-the-very warm place time to warm up to the desired temperature and, accordingly, to soften.

To improve the efficiency of the plant heaters have a fan, you hot? And what these preforms?

I walk around the machine with the other hand to show you how to make a bottle.

After harvesting hot, it gets between the halves here this mold. The halves are closed tightly and the inner cavity of the workpiece is supplied with compressed air. The blank is inflated like a balloon, taking all the contours of the mold.

And at the exit already have the finished product.

What's next? Then the brand new bottle lining up on such overhead conveyor. The conveyor air is blown from the inside, it is done for two reasons, the first - for the cooling of bottles, the second - to prevent the ingress of particles inside the bottle in the air. Purging is carried out with three fans, they are clearly visible in the frame. At the entrance there are fans air filters.

Now, after a short wait, the bottles fall into the dispenser

Although the bottle and clean, but still the first thing - washing. With a bottle conveyor fall into the clutches this octopus. It looks like a fragment wash carousel.

That's a general view of this part of the machine

Bottle washed and ready to take a drink.

The bottle is then transferred to a section where it will be filled with beer and bottled up. Transparent doors opened at our request, in order that we can properly remove the mechanisms of this machine. When we made our photographic business, closed the door immediately - cleanliness above all.

Carousel Carousel ... then poured a beer in a bottle ...

... And then the bottle is sealed.

We go further up the chain ...

After filling - automatic control.

This checks the absence of inclusions in the filled bottle.

The bottle is then passed into the hands of machine, which is glued label.

Then lean ryadochkom ...

... Fall to the packaging machine.

At the entrance to the car of the bottles formed packs of 6 pieces.

Then, six bottles wrapped film. And out in the hot part of the machine, where the film melts and gives a small shrinkage, allowing the bottle firmly fixed.

That's the finish. The finished pack will be charged to workers and stacked on pallets. And it is the only operation where human hands relate to production, everything, absolutely everything makes automation.

Beer stacked in pallets, which are then razvezut of trading networks.

Finally, a general view of almost the entire plant.

Source: kak-eto-sdelano.livejournal.com

Tags

See also

Aprelevka Plant Museum records.

Protein Diggers or which produces a protein biochemists

Most of the souvenirs that sells History Museum in Washington - Chinese-made

Sepp Holzer Permaculture - 10 times more effective than traditional agriculture!

5 fantastically wealthy families that have lost condition

Crazy ideas to save the planet

Army of Georgia

Opponent in Sweden, our technology is the best

Travel Circum-Baikal Railway

Uzbekistan-Mahalla people