763

How do Opel

Today I am pleased to present to you a report from the Opel plant in Rüsselsheim. In 1863, Adam Opel discovered in Russelsheim factory producing sewing machines here now one of the largest and oldest car factories in the world. There are 16 000 people and annually produced 180,000 vehicles.

55 photos via zyalt

01.

02. Employees move on bicycles. To the right is visible footpath.

03. These deliver the metal of the stamped body parts. In the factory make Insignia and Astra, but in the press shop make blanks for all models, which are then sent to other plants, including in Russia.

04.

05. This is the largest injection molding at Opel.

06. The entire plant is occupied huge presses, hundreds of them here. During operation, press floor trembles slightly, as in the small earthquake.

07.

08. Matrix.

09.

10. Matrix are marked with different colors - depending on the vehicle model.

11.

12.

13.

14. This machine is punched to form a small twenty minute.

15.

16.

17. Stand with reference samples. From each batch of randomly selected several items and compared to the benchmark.

18. This new press. The machine is worth 40 million euros! It can be a time stamp just one side of the machine. Press weighs 6,500 tons.

19.

20.

21. After a few moments out side of the three-door Astra

22. Then he cut off part of the excess metal

23. And on the cart is sent to the conveyor assembly shop.

24.

25. In the welding shop are all fully automated, so you can watch only from above.

26. The welding shop is working in two shifts. At each change of 200 people. In the body assembly work 700 robots, each of which is worth 100 000 euro. Production at 98% automated.

27.

28.

29. Where do the robots are not people. If anyone enters the area of robots - production stops.

30.

31. Roof laser welded. In Opel Insignia - 4,500 welding points.

32. Naked body weighs 400 kg, and the painting takes 8 kg of paint and varnish. Unfortunately, the process to remove paint is not allowed.

33.

34.

35.

36. In the assembly shop employs 2,000 workers in two shifts.

37.

38. A total of 16 000 employees of the plant. Directly involved in the assembly of 7000, 5000 administration.

39.

40.

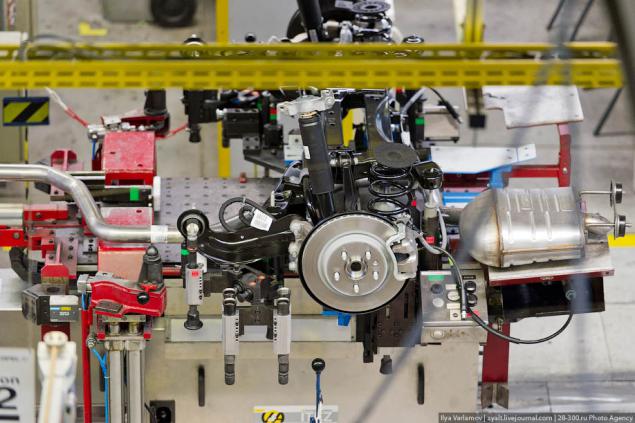

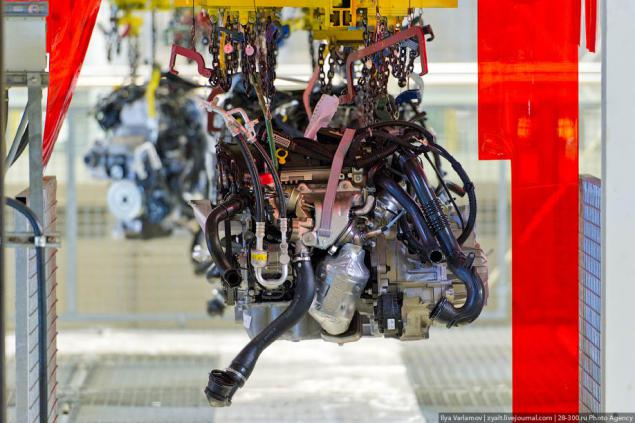

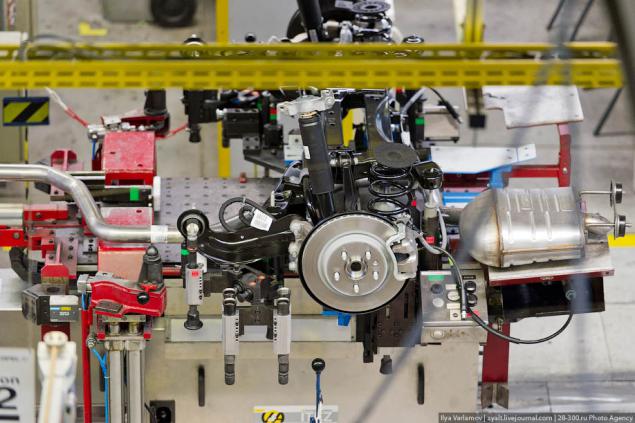

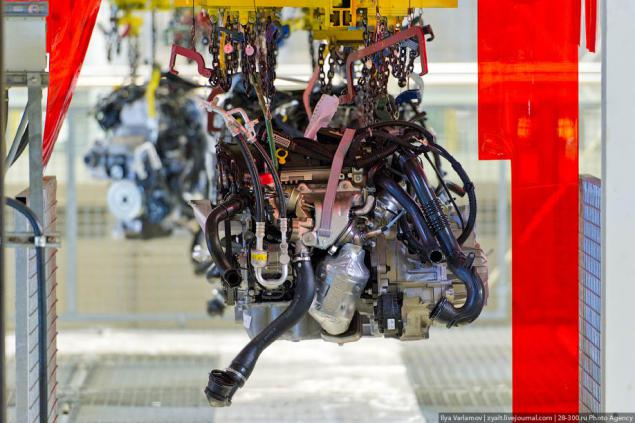

41. All engines are different

42. In total, the pipeline is fed up to 40 kinds of motors. Computer monitors that each motor is found his car.

43.

44. The process, when the engine is connected to a body called the "wedding ceremony".

45. Workers work in groups of 5 people. In this building a special cycle time - 65 seconds. For 65 seconds, the worker must do some stage work. If he does not have time - the conveyor stops.

46. Everywhere there is a special rope if to pull for it - the conveyor stops and starts playing music. Each team has its own music. According to her foreman knows who the problem and solve it quickly.

47. At the same assembly line can produce up to 9 different models of cars. Note - that all the cars on the assembly line are different. Not only the color but also the model. Since the assembly is automatic, there is no need to produce only one model. Assembling the host computer.

48.

49. Almost finished car.

50. After the assembly a car passes a series of tests. For example, he poured water into a special chamber to check for leaks. Then he passes a small obstacle. The driver listens to the car behaves on the bumps.

51. Brand new three-door Astra.

52 Amps. It is a pity, in Russia, they are not supplied. And we do not have yet of chargers for automobiles.

53.

54. collect the car from the factory takes away train.

55. This hall, where the fate of the new models! The screen shows the model, teams from different countries can work and condemn it ...

Source:

55 photos via zyalt

01.

02. Employees move on bicycles. To the right is visible footpath.

03. These deliver the metal of the stamped body parts. In the factory make Insignia and Astra, but in the press shop make blanks for all models, which are then sent to other plants, including in Russia.

04.

05. This is the largest injection molding at Opel.

06. The entire plant is occupied huge presses, hundreds of them here. During operation, press floor trembles slightly, as in the small earthquake.

07.

08. Matrix.

09.

10. Matrix are marked with different colors - depending on the vehicle model.

11.

12.

13.

14. This machine is punched to form a small twenty minute.

15.

16.

17. Stand with reference samples. From each batch of randomly selected several items and compared to the benchmark.

18. This new press. The machine is worth 40 million euros! It can be a time stamp just one side of the machine. Press weighs 6,500 tons.

19.

20.

21. After a few moments out side of the three-door Astra

22. Then he cut off part of the excess metal

23. And on the cart is sent to the conveyor assembly shop.

24.

25. In the welding shop are all fully automated, so you can watch only from above.

26. The welding shop is working in two shifts. At each change of 200 people. In the body assembly work 700 robots, each of which is worth 100 000 euro. Production at 98% automated.

27.

28.

29. Where do the robots are not people. If anyone enters the area of robots - production stops.

30.

31. Roof laser welded. In Opel Insignia - 4,500 welding points.

32. Naked body weighs 400 kg, and the painting takes 8 kg of paint and varnish. Unfortunately, the process to remove paint is not allowed.

33.

34.

35.

36. In the assembly shop employs 2,000 workers in two shifts.

37.

38. A total of 16 000 employees of the plant. Directly involved in the assembly of 7000, 5000 administration.

39.

40.

41. All engines are different

42. In total, the pipeline is fed up to 40 kinds of motors. Computer monitors that each motor is found his car.

43.

44. The process, when the engine is connected to a body called the "wedding ceremony".

45. Workers work in groups of 5 people. In this building a special cycle time - 65 seconds. For 65 seconds, the worker must do some stage work. If he does not have time - the conveyor stops.

46. Everywhere there is a special rope if to pull for it - the conveyor stops and starts playing music. Each team has its own music. According to her foreman knows who the problem and solve it quickly.

47. At the same assembly line can produce up to 9 different models of cars. Note - that all the cars on the assembly line are different. Not only the color but also the model. Since the assembly is automatic, there is no need to produce only one model. Assembling the host computer.

48.

49. Almost finished car.

50. After the assembly a car passes a series of tests. For example, he poured water into a special chamber to check for leaks. Then he passes a small obstacle. The driver listens to the car behaves on the bumps.

51. Brand new three-door Astra.

52 Amps. It is a pity, in Russia, they are not supplied. And we do not have yet of chargers for automobiles.

53.

54. collect the car from the factory takes away train.

55. This hall, where the fate of the new models! The screen shows the model, teams from different countries can work and condemn it ...

Source: