705

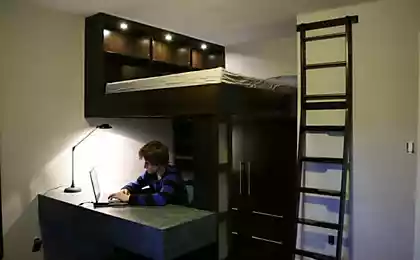

Bunk bed in the nursery

As I began to drink in, all senses, a bunk bed.

Children do not have much, so two beds put in it would have been problematic, space would remain quite small. It was decided to buy a bunk bed. Shopping trip, I realized that something more or less decent and stable costs around $ 500. Realizing that, in principle, nothing complicated about it, he decided to make a bed.

[next]

It means so. In the absence of most of the instruments, it was decided to find or order of the board is already polished, and preferably exactly napilennye. All STROYMARKET city were, at best, planed, and thin, that I no it does not fit. In the construction market has been a problem, even with planed wood. Telephoned woodwork, only one agreed to make the necessary me boards of beech for the price of $ 1000 per cubic meter. Since the original budget is very limited, the search continued. On one of the construction markets still have been found boards more or less suitable for my requirements - pine boards 35 * 105 and 25 * 105 at a price of $ 500 per cubic meter. Boards have already been polished, so that was just cut to the proper size, make the necessary slots and proceed to the assembly.

That so many were purchased for the first time (hereinafter dokupal another boxes), took on the frame board 35 * 105, on ledges and boxes 25 * 105.

25 ph

Sampling smooth grooves, even on soft pine, chisel, not an easy task. Namuchalas with two slots, it was decided to get somewhere in the router, or at least buy. Calling friends had found this instrument, and the work went.

So look rack with slots

Putting it quietly.

Further assembly is already in place setting bed, as collected simply would not pass in the door)))

For the stairs and use the board 35 * 105 and two shovel handles 1, 2 m. From cuttings turned 4 steps of 45 cm. Unfortunately, the process was so fascinated that I forgot to take pictures, so that further assembly only in words. The assembly took place in the frame of the bed adhesive (soudal wood) + screws, screw screwed 40-50 mm wood must keep.

The boards of stairs crown drill-holes are not, choose wood cutter. Steps came into the holes pretty tightly, so Sadilov only glue.

Here it is, with a ladder frame. The bed was opened furniture varnish, water-based, after the first layer is sanded fine sandpaper to remove the pile

Instead slats were bought planed boards on sale 20 * 140, also varnished in two layers. Bought mattresses and bed brought into operation.

8.

9.

10.

11.

12.

13.

Now it is the turn of boxes. For they had taken the same board 25 * 105, furniture castors.

15.

16.

17. Mark up

18

19. Drill

20.Vse board connected to each other on the glue and tightens screws, turned out pretty strongly.

21.Pazy under the rollers and handles as chosen cutter and hacksaw. The facade of the box was placed on the dowels and glue to be beautiful.

22.Vse is also varnished.

Posted in [mergetime] 1390057716 [/ mergetime]

23.

24.Vot final result.

25. The children are happy, on the second floor playing together. Bed turned out pretty hard and firm, is monolithic. Total got about $ 130 and a few weekends and evenings for a couple of boxes. That's all I wanted to say! Ready to listen to criticism.

Source:

Children do not have much, so two beds put in it would have been problematic, space would remain quite small. It was decided to buy a bunk bed. Shopping trip, I realized that something more or less decent and stable costs around $ 500. Realizing that, in principle, nothing complicated about it, he decided to make a bed.

[next]

It means so. In the absence of most of the instruments, it was decided to find or order of the board is already polished, and preferably exactly napilennye. All STROYMARKET city were, at best, planed, and thin, that I no it does not fit. In the construction market has been a problem, even with planed wood. Telephoned woodwork, only one agreed to make the necessary me boards of beech for the price of $ 1000 per cubic meter. Since the original budget is very limited, the search continued. On one of the construction markets still have been found boards more or less suitable for my requirements - pine boards 35 * 105 and 25 * 105 at a price of $ 500 per cubic meter. Boards have already been polished, so that was just cut to the proper size, make the necessary slots and proceed to the assembly.

That so many were purchased for the first time (hereinafter dokupal another boxes), took on the frame board 35 * 105, on ledges and boxes 25 * 105.

25 ph

Sampling smooth grooves, even on soft pine, chisel, not an easy task. Namuchalas with two slots, it was decided to get somewhere in the router, or at least buy. Calling friends had found this instrument, and the work went.

So look rack with slots

Putting it quietly.

Further assembly is already in place setting bed, as collected simply would not pass in the door)))

For the stairs and use the board 35 * 105 and two shovel handles 1, 2 m. From cuttings turned 4 steps of 45 cm. Unfortunately, the process was so fascinated that I forgot to take pictures, so that further assembly only in words. The assembly took place in the frame of the bed adhesive (soudal wood) + screws, screw screwed 40-50 mm wood must keep.

The boards of stairs crown drill-holes are not, choose wood cutter. Steps came into the holes pretty tightly, so Sadilov only glue.

Here it is, with a ladder frame. The bed was opened furniture varnish, water-based, after the first layer is sanded fine sandpaper to remove the pile

Instead slats were bought planed boards on sale 20 * 140, also varnished in two layers. Bought mattresses and bed brought into operation.

8.

9.

10.

11.

12.

13.

Now it is the turn of boxes. For they had taken the same board 25 * 105, furniture castors.

15.

16.

17. Mark up

18

19. Drill

20.Vse board connected to each other on the glue and tightens screws, turned out pretty strongly.

21.Pazy under the rollers and handles as chosen cutter and hacksaw. The facade of the box was placed on the dowels and glue to be beautiful.

22.Vse is also varnished.

Posted in [mergetime] 1390057716 [/ mergetime]

23.

24.Vot final result.

25. The children are happy, on the second floor playing together. Bed turned out pretty hard and firm, is monolithic. Total got about $ 130 and a few weekends and evenings for a couple of boxes. That's all I wanted to say! Ready to listen to criticism.

Source: