Jobs of the future - training robots interact with people

Bashny.Net

Bashny.Net

Decade научно-фантастических Film taught people бояться Robots : they enslave us, chased us off the face of the Earth, заберут our jobs . In real life, people and machines are trained to do together more than they could do separately. Here are six companies where обучение robots in full swing, and people get valuable skills in technology.

AUTODESK

The robot learns to draw em>

The new short film «Love Artoo» , famous droid from the "Star Wars" is crazy about domed mailbox. The film, written and directed by Evan Atherton Autodesk engineer, recalled a scene in which the lovers posing for a sketch that depicts a robot. Not agreeing to forgery, Atherton asked his colleagues Autodesk, David Thomasson, is it possible to teach the robot sketch actually. Why not? They first trained the robot to draw online, directing his hand on the canvas, and, ultimately, its algorithm was able to take over the process. Now a team of robot learns to draw and use motion capture technology so that it can mimic human actions and adapt to create more original works. The hope, said Thomasson, that robots will not only "practical tool, but also a creative partner».

RAYTHEON

Fast and harmonious training em>

One of the robots company Raytheon, Tucson em>

Raytheon plant in Tucson has an area of 14,300 square meters, and there is full of robots and people working together. Raytheon is building their robots: the company buys and installs a common programming interface to make it easier to teach them and reprogram. When the robot need to learn something, the problem is first simulated by software company Raytheon, and then set the robot for initial testing. The whole process, according to the operator, Charles Scott, can take anywhere from a few hours to 1 day. After that, the model is updated and installed software robots already in use.

This is a robot, but the guys did their oriented solutions for our products, which are very complex, - said Kim Ernzen, vice president of operations.

Blockquote>

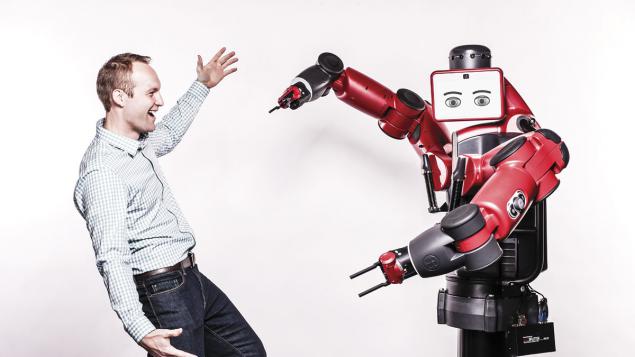

RETHINK ROBOTICS

Tips - this productivity em>

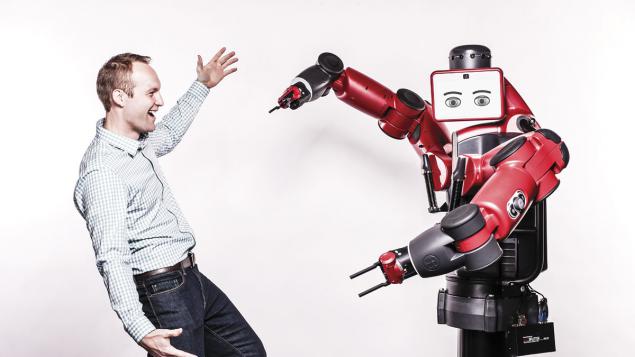

The robot Baxter with Nate Koontz em>

Engineer Nate Kunz is the coach of the robot Baxter Rethink Robotics . The process, he usually begins with a study of the photos illustrate the problem, or that the customer (among customers - John Derry and Kaiser Permanente) wants to automate long before установки Baxter on the assembly line . Total training time can take anywhere from a few hours to a month, depending on complexity. Rethinking the problem often spends Baxter to learn new tricks, such as working as a bartender or a game of Connect Four. Games can push on new ideas for software. One such solution came from an employee who taught Baxter make coffee. As a result, the process is used for quality control of beverage. Baxter has been trained to mix the drink, study its sediment and pour it just as he had been taught in the manufacture of coffee.

GENERAL MOTORS

Approaching robotics em>

The robot works hard at the company's plant in Orion em>

Some unfortunate people in the GM plant in the town of Orion, Michigan, was boring hard work they filmed spare tire conveyor and stacked them, depending on the vehicle for which they were intended. Not surprisingly, the first collaborative robot, which appeared at the factory in January, was instructed to lay down their tires. The most difficult thing was to teach him to maneuver in a crowded workspace where people usually are separated by a distance of less than a meter. "Manufacturing is a contact sport," - says engineer GM Marty Linn. GM abandoned the sensitivity of the sensors and power robots went through a lot of rehearsals, using real props and people. People had to learn to work with the robot, survive the "information week" testing. The robot is now considered part of the team.

A. ZAHNER CO.

Performs welding works no worse than a man em>

Bill Zahner and his robot em>

Architects around the world, please contact A. Zahner Co. from Kansas City for the huge steel structures and facades to order that adorn buildings, such as the Guggenheim Museum in New York, Dallas Cowboys Stadium and Art Wall in Doha. For many years, workers at Zahner reluctant to accept robots, while the staff and director Bill Zahner did not understand that in this way they will release skilled craftsmen to carry out more complex work on large-scale projects.

If you are doing some things faster, it allows us to develop more creative aspects - Zahner said.

Blockquote> The first robot arrived in 2007 and began to learn by watching how the engineers welded points on the arcs of up to 4, 5 m. It is followed on the same points, based on the movements that showed engineers. Welds made robot, turned out to be worse than those that made the master. Zahner said that perhaps even better, because robots do not get tired at the end of a long day.

ABB ROBOTICS

Simple as iPhone em>

The robot Yumi (ABB) em>

new robot from ABB Robotics - YuMi - This two-handed employee for companies that have not previously used a similar technology. Its user interface was inspired by the iPhone, presenting a "complex product where the user does not need to know a lot," says Bertil Torvaldson ABB engineer. YuMi can be programmed for basic tasks, with only app on the tablet, but Now more advanced users use the full set of software tools for tasks such as electronics manufacturing. Of all the robots YuMi, probably easiest train.

Source: geektimes.ru/company/robohunter/blog/252576/

Tags

See also

What else don't we know about time travel

AMD has promised to erase the line between movies and games

Electric Porsche and Audi will compete with Tesla

Robots will be deprived of legal work (routine)

Manager US 911 told about his work

As technological innovations will change everyday life

Startup Knightscope ready to operate the robot guards man-sized

How to teach a robot to cook?

Chased robots restaurant staff

Stephen Hawking about robots in the labor market