Professions of the future: 3D printing in medicine

Bashny.Net

Bashny.Net

Hi, Habr!

3D printing slowly penetrates our lives as it once was with mobile phones and even earlier - with computers. Who we are, however, much less surprised by some innovations in the field of IT. You have certainly not forgotten the news, which tells about the 3D-printed on the printer vertebra implanted in a living person. Nearer the time when the body parts and organs can be literally printed.

New opportunities and new requirements to specialists.

"External» prosthetics I specifically did not touch, because it is a separate and very complex topic.

Dental h4> In 2012, a first operation to implant the implant mandible printed on a 3D printer. Material - titanium. Artist - Company LayerWise.

spine h4> Problems with intervertebral discs - quite a common thing. Recently, I ran with it: I, as the neurologist, one of the cervical vertebrae is chamfered, that is somehow he "skived" and standing correctly. Result sports. But Plushenko because somehow continues to skate with the artificial vertebra - and alive.

Skull h4> Using bulk printing 75% patient's skull had been replaced . Good indicator. This operation took place March 4, 2013 in the US, it was made after two weeks of work with the scanned model of the skull of the patient. The result follows the shape of the smallest details.

Other bones h4> Why 3D printing in terms of prosthetic bone so effective?

Joints h4> Earlier this year, the US got the first man who implanted knee joint, printed on a 3D printer.

The auricle h4> This is not just a sink, and the present bionic ear. Only to the person it is not yet sewn.

Liver h4> To study medicine in 2013, scientists have been able to print on a 3D printer liver tissue. As a material used hepatocytes, stellate cells, and epithelial cells lining the blood vessels.

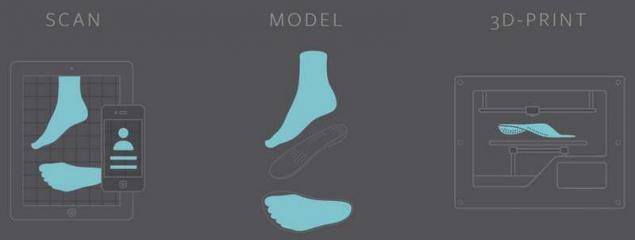

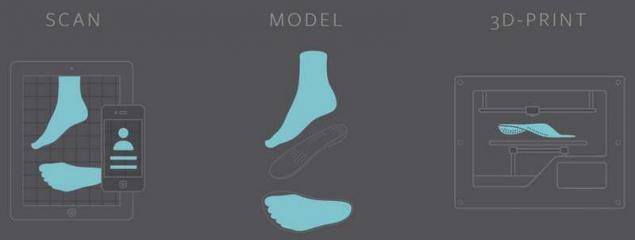

Orthopedic products h4> The idea on the surface: print orthotics on 3D printer after scanning becomes very easy and fast.

Help during operations h4> having before volumetric 3D model, the surgeon will be much easier to navigate inside a living person during surgery.

3D printing slowly penetrates our lives as it once was with mobile phones and even earlier - with computers. Who we are, however, much less surprised by some innovations in the field of IT. You have certainly not forgotten the news, which tells about the 3D-printed on the printer vertebra implanted in a living person. Nearer the time when the body parts and organs can be literally printed.

New opportunities and new requirements to specialists.

"External» prosthetics I specifically did not touch, because it is a separate and very complex topic.

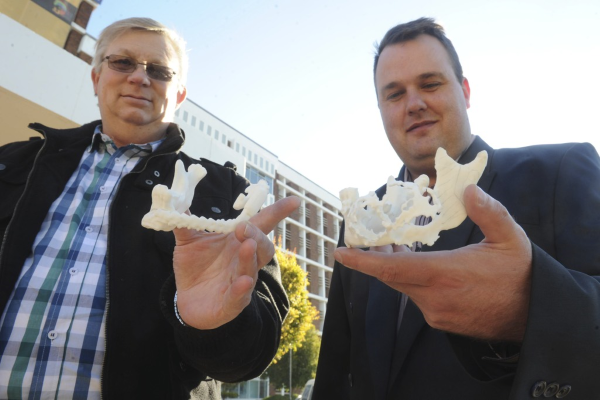

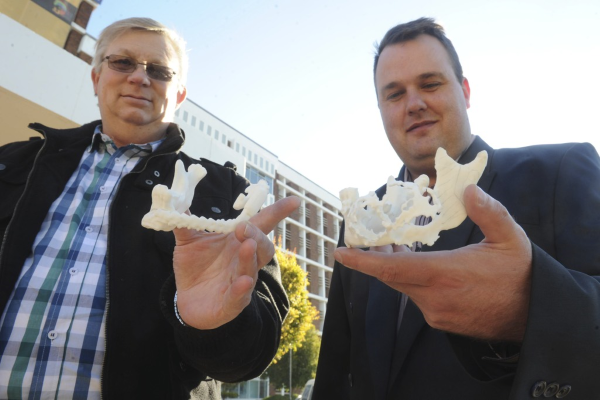

Dental h4> In 2012, a first operation to implant the implant mandible printed on a 3D printer. Material - titanium. Artist - Company LayerWise.

This summer, two more "lucky" become owners of new mandible. One jaw lost due to a tumor, and the second broke it. Apparently, very strongly, so could not collect.

This dental surgeons of the hospital Kimberly.

3D printing technology already used in dentistry since 1999. A pioneer in the area - the company Align Technology, launched production and sales for thorough teeth as an alternative to braces.

spine h4> Problems with intervertebral discs - quite a common thing. Recently, I ran with it: I, as the neurologist, one of the cervical vertebrae is chamfered, that is somehow he "skived" and standing correctly. Result sports. But Plushenko because somehow continues to skate with the artificial vertebra - and alive.

Crown of developments in this area - a recent operation on the spine of the Peking scientists 12-year-old boy with a malignant tumor of the spinal cord. The material from which made the vertebra - porous because change vertebra, as scientists believe, is not necessary: it simply will acquire bone, that is to become an integral part of the body.

The only negative, but a bunch of pluses: will take a little longer rehabilitation than with traditional materials.

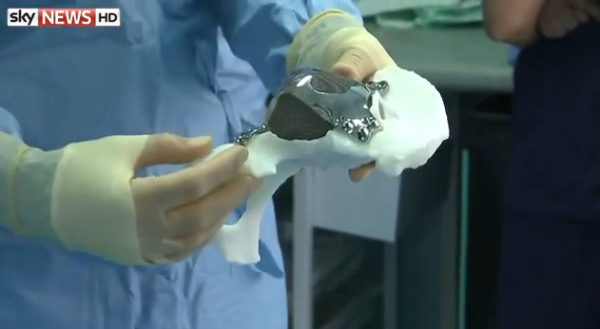

Skull h4> Using bulk printing 75% patient's skull had been replaced . Good indicator. This operation took place March 4, 2013 in the US, it was made after two weeks of work with the scanned model of the skull of the patient. The result follows the shape of the smallest details.

According to the Oxford Performance Materials, 300 to 500 people in the US each month may be patients who require such operations. They are victims of road traffic accidents, soldiers and cancer patients with tumors in the skull.

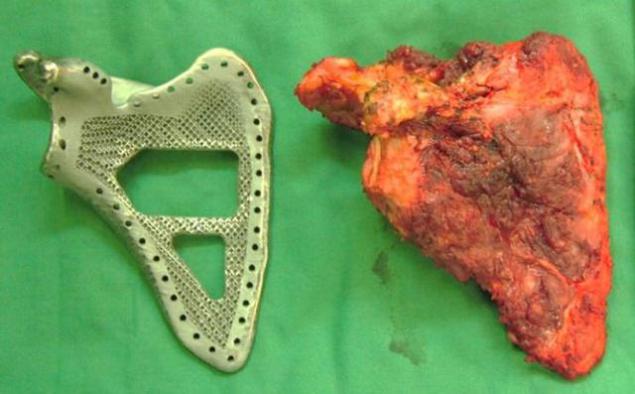

Other bones h4> Why 3D printing in terms of prosthetic bone so effective?

1) Speed. Using traditional techniques of casting prostheses - a long process.

2) Easy. Weight, incidentally, can be adjusted by changing the porosity of the titanium prosthesis.

3) Porosity. This quality allows the prosthesis will "grow into" living tissues.

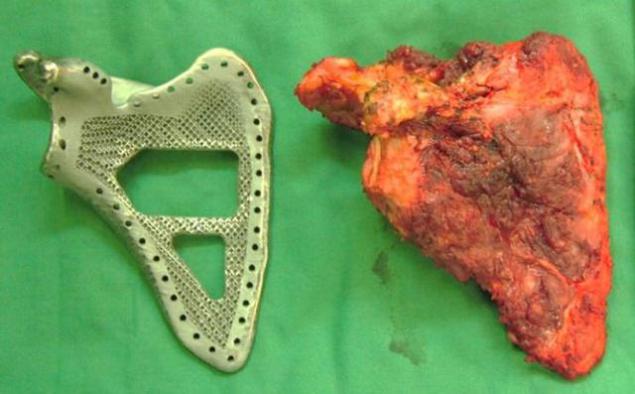

In this June last few transactions in the same China, in which patients were implanted with the clavicle, scapula and right iliac bone of the pelvis. Indications for surgery - tumors.

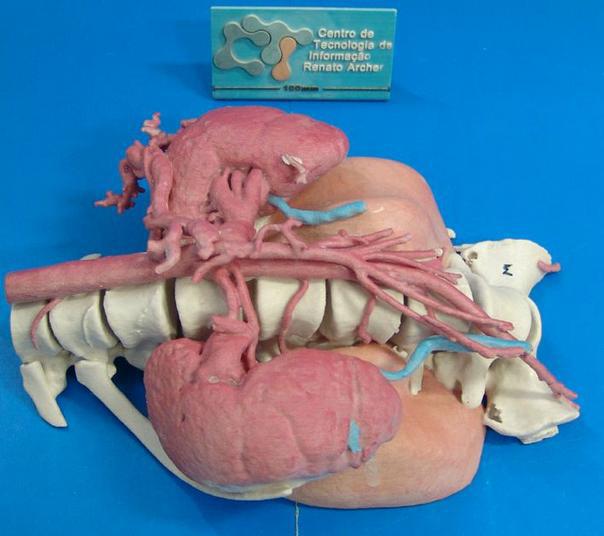

It's printed on a prosthetic blades. I>

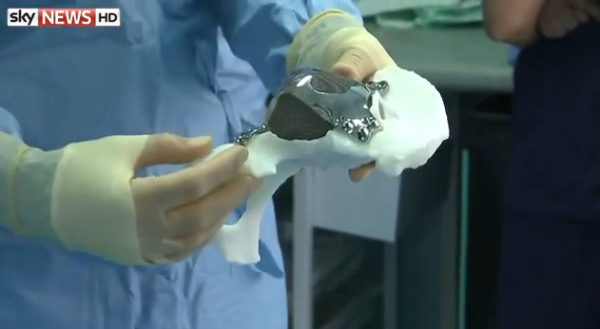

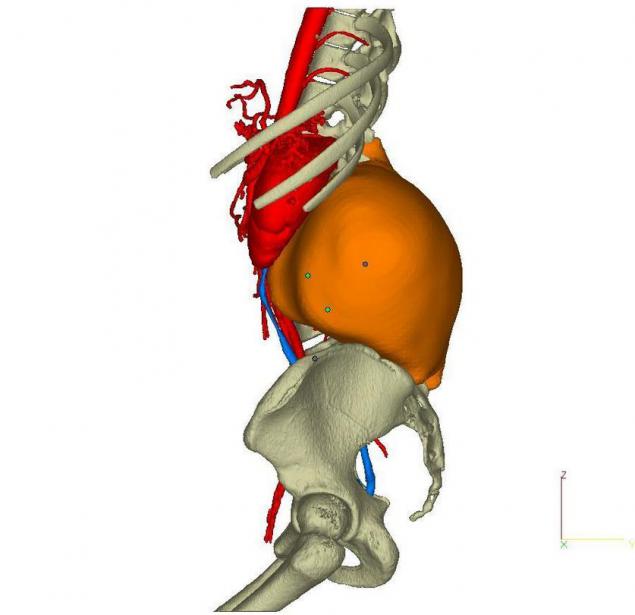

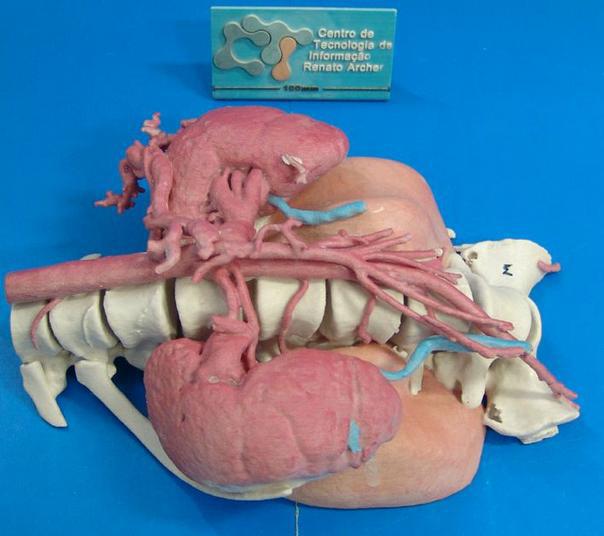

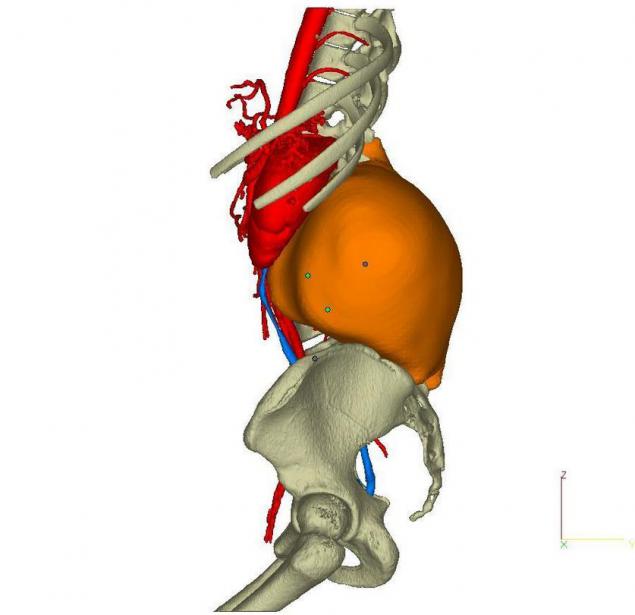

And here in the hands of doctors, we see no prosthesis, and a 3D model of the pelvis. With the sight of such a model, the doctors were able to work quickly and efficiently during surgery.

Joints h4> Earlier this year, the US got the first man who implanted knee joint, printed on a 3D printer.

It is better than conventional implants? The essence lies in the "little things": usually for knee replacement prosthesis is selected, and then grind the bone to approach him. In the case of the seal of the developers took the results of computed tomography and made joint that most naturally suited to the patient.

Companies engaged in this work Conformis. According to Mike Myers, who now runs fine and even plays golf, and does not stop after each quarter, foreign body, he does not feel in the body.

Another important difference between this type of joints from traditional steel and plastic, "classics" in 10-20 years will have to change.

In Britain this year, underwent surgery for a hip replacement printed. 71-year-old grandmother to her feet. Material - again titanium powder.

The auricle h4> This is not just a sink, and the present bionic ear. Only to the person it is not yet sewn.

This device is adapted with live human cells comprising an inductive radio antenna. This is still a concept, on which more work. He created for approbation use of nanoelectronics in 3D printing.

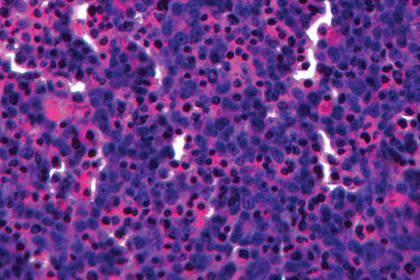

Liver h4> To study medicine in 2013, scientists have been able to print on a 3D printer liver tissue. As a material used hepatocytes, stellate cells, and epithelial cells lining the blood vessels.

Biopechati process.

The main problem at the moment of using 3D printing prosthetics bodies - a blood supply. Because every cell in the tissue is near the capillaries. While this problem scientists have not decided.

Orthopedic products h4> The idea on the surface: print orthotics on 3D printer after scanning becomes very easy and fast.

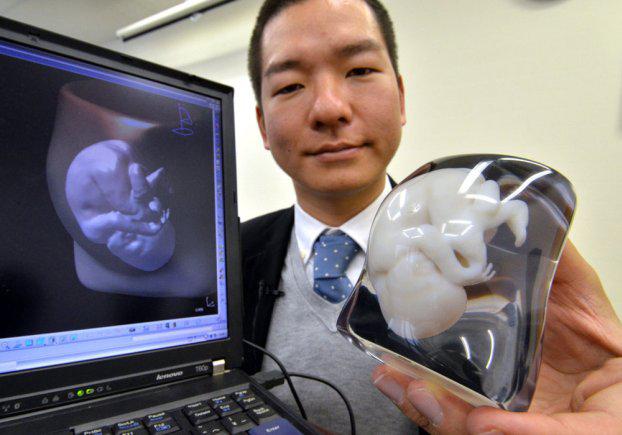

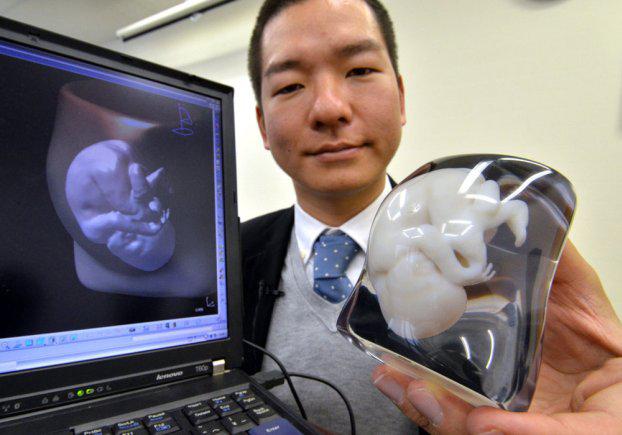

Help during operations h4> having before volumetric 3D model, the surgeon will be much easier to navigate inside a living person during surgery.

Especially, when the operation is on the little girl, whose declared inoperable cancer. Tumour girl of twelve, whose models we see in these images, is too close to the spine, and was surrounded by healthy tissues, organs, veins and arteries. This dangerous operation was successful, because the doctors used this 3D printed model and carefully planned operation with it.

Also now collect library 3D layouts of hearts around the world. Printed heart also helps doctors plan the operation, because one thing - to see the results of the scan, and another - to keep their hands in full size.

3D printing in the field of medicine has not yet revealed its full potential. Many believe that on the approach - print organs in real time. Perhaps before that left 10-12 years. So doctors will not wait for the donor will have an accident, leaving the heart, doctors simply take the necessary tests and print the appropriate authority.

History bulk printing 1980s leads us to this possibility. And then create new jobs and business opportunities: companies whose purpose - helping surgeons to conduct operations, development and creation of new types of prostheses and study materials as well as testing of drugs and the creation of tissue by biopechati.

New features and trends give rise to new requirements for specialists. So there is a profession of "bio-architects" in the field of 3D printing.

Bodies of each person is not the same, and the injury during transplantation can be reduced by adjusting the size and the unique features of the new body. If we can print a new body, we can also use it all the best features of the old body, but fix bugs. It turns out we need a specialist who knows medicine, anatomy, able to work with 3D models, 3D printing understands and is able to literally finalize new printable body.

Source: habrahabr.ru/post/237699/

Tags

See also

All about mobile - myths and reality.

14 photos of the kids, who are experts in walks. A vacation had just begun!

Hybrid versions will get all models of Porsche

How mankind will be released from the cruel experiments?

To start now to get maximum benefit through 5 years

How to make a home a source of vitality and energy

10 tricks that will allow you to charge your smartphone for a few days

Inventions that changed the mobile phone industry