How to make heavy steel castings

Bashny.Net

Bashny.Net

Today we go to the shop of one of the leading foundries in Russia, specializing in the production of large and medium-sized castings from carbon and low-alloy steels. Tired office? Then be sure to look for the cat. Foundry "Promtractor Promlit" was founded in 1977 as part of Cheboksary industrial tractors, and is now one of the most modern foundries in Russia, producing castings railway destination and housing blanks tractors.

Let's start with cores. They are used to form internal cavities of the casting.

There is a form for casting, in which the rods are inserted. Then he poured molten metal cools, taking the form, and the rods are removed.

The plant produces a lot of different metal products, and therefore need a variety of bars.

Workers watch! :)

The new automated system, which includes mixers with complex control systems and quality control for the mixture of forms and rods.

Before preparing the mixture almost manually, and now everything is in the same complex.

This shop made molds and cores.

Steel production is produced in arc furnaces with a capacity of 25 tons.

Metal melting furnaces used in the electric arc heating effect.

The temperature in the furnace can reach 1800 degrees.

Molten metal after arc furnaces.

The steel is poured directly into a mold, or sorted for transportation and filling out forms.

Foundry №1 is the main foundry production.

Hot to work! :)

The shop is equipped with five electric arc furnaces.

Control of the melting process in furnaces.

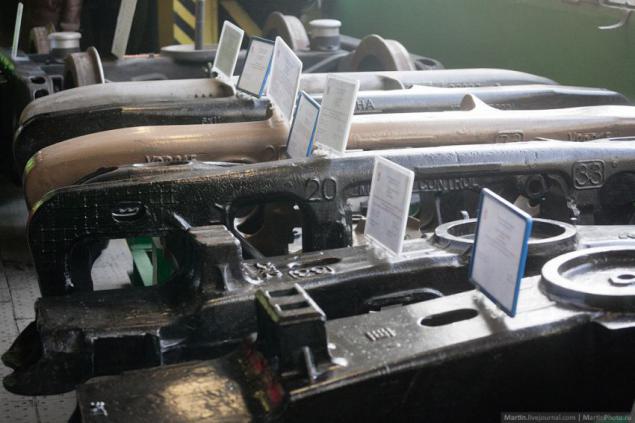

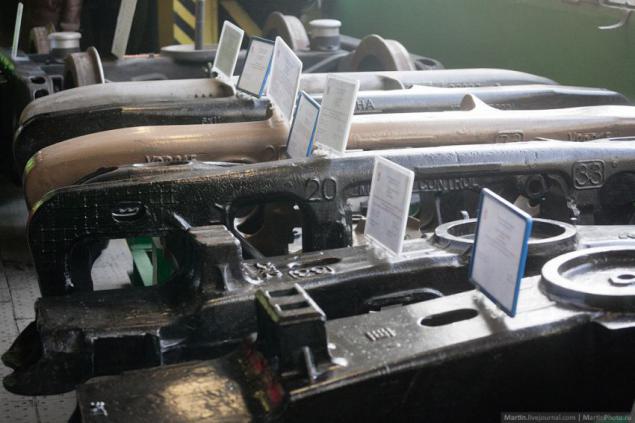

The final products. The plant manufactures components for railway carriages Railways and case details of tractors.

Source: kak-eto-sdelano.livejournal.com

Let's start with cores. They are used to form internal cavities of the casting.

There is a form for casting, in which the rods are inserted. Then he poured molten metal cools, taking the form, and the rods are removed.

The plant produces a lot of different metal products, and therefore need a variety of bars.

Workers watch! :)

The new automated system, which includes mixers with complex control systems and quality control for the mixture of forms and rods.

Before preparing the mixture almost manually, and now everything is in the same complex.

This shop made molds and cores.

Steel production is produced in arc furnaces with a capacity of 25 tons.

Metal melting furnaces used in the electric arc heating effect.

The temperature in the furnace can reach 1800 degrees.

Molten metal after arc furnaces.

The steel is poured directly into a mold, or sorted for transportation and filling out forms.

Foundry №1 is the main foundry production.

Hot to work! :)

The shop is equipped with five electric arc furnaces.

Control of the melting process in furnaces.

The final products. The plant manufactures components for railway carriages Railways and case details of tractors.

Source: kak-eto-sdelano.livejournal.com

Tags

See also

How to make chocolate

Photo galleries on how to produce rubble.

How to produce natural cosmetics

How to produce plywood (13 photos)

The history of evolution Office

How to produce PLA for 3d-printer. Report from the workshop

How to produce a model shoes in India

Technical innovations that changed the sport

How to make the perfect box (38 photos)