Table knife from the nail for a doll.

Bashny.Net

Bashny.Net

Table knife, of course - a blunt object. Tomato or smoked sausage on paper, they do not cut yourself nicely, but once in cultural dining doll houses of Europe it is present, we will try to comply.

Samodelnichal dno, he's fun, and Fota kamentah!

On completion of the process will be announced !!!

Nail, in turn, the subject of seemingly simple, narrow section proletarian destination. Tear-off calendar, a colander or on his jersey hanging in vintage interior - the most it.

When boiling perturbed mind, the nail can be used as a stylus, writing out on the hood of a neighbor wishes indicating direction, which knows no navigator in the world. But the most important thing when dealing with a nail, it does not give him good to get into children's hands.

In this case, the scope of the nail in the household repeatedly expands and unpredictably. From burying it in a flower pot or a pan of porridge before drawing it on a laptop, walls and lacquered furniture. It goes tools and creative leisure in free time, conveniently stored in my father's mother's shoe or boot, and even better - in the drum of a new washing machine.

Personally, after meeting with the screwdriver, a nail look with disdain on the rocker arm or torch, but a strategic reserve of rusty nails in case of economic or spiritual crisis, have and keep in the closet next to the spinning wheel and bast shoes.

Frankly, from a nail can make a lot of useful things in the economy, for example - "bullet" for the slingshot. But this I tell you I can not. I've got a blog peaceful and correctly made a slingshot if not handled properly - a serious thing, by the way!

Another thing, if from a nail to make such a harmless thing like a knife.

"In short, Sklifosovsky!" - I hear the cheers of those who have read this far and, therefore, turn to the topic of the post.

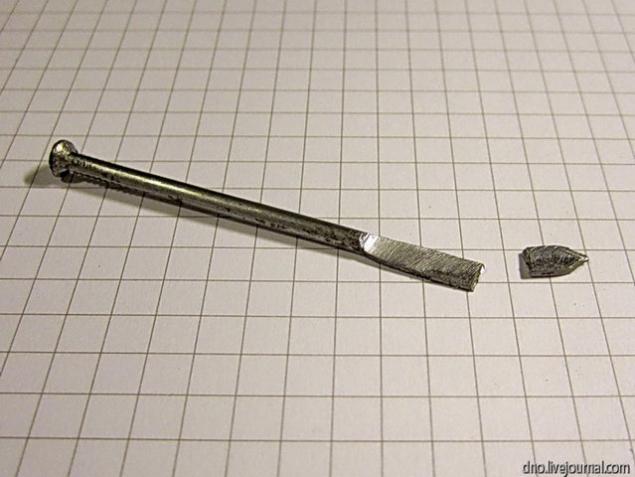

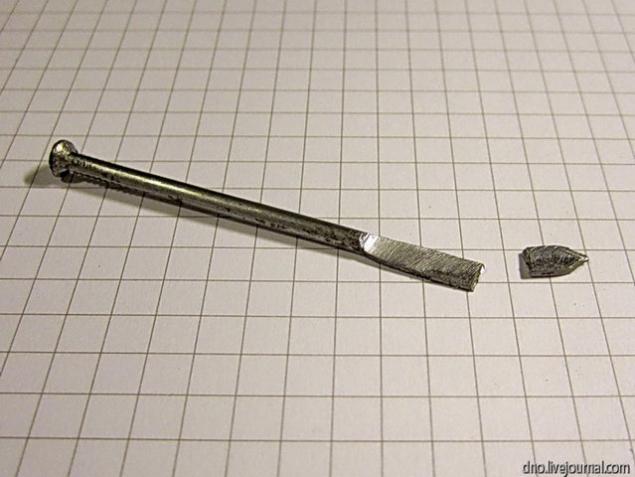

Now I'll tell you how to convert home nail diameter of 2, 5 mm in a simple table knife on a scale of 1 to 12.

For a start, it is necessary to flatten the end of the nail (that you can not do, but then the description of the manufacturing process will be reduced to the phrase "a nail with a file handle," which, as regular readers realize, not our method).

Search light the way - this is for mountain climbers and astronauts. We are wading into the kitchen under the cover of night in hopes to catch a refrigerator surprise risk at every step to meet the competition.

So, what am I doing? So, to flatten the end of the nail length of about 1, 5 cm, we need a hammer and anvil. When anvil you home for some reason was not possible to use, for example, a rail. If suddenly your rail first, nailed to the sleepers, and secondly, for it periodically pass commodity and passenger trains, keep in mind that walking near railroad tracks with a hammer in one hand and nail to another can result in confiscation of not only the above objects production threat to the world community, but also yourself.

Do not forget that the relevant authorities are not heard touching stories like the story about the knife from a nail, and even a link to this record does not relieve you of the passage forcibly mental examination.

In any case, better a little medical treatment, and then who knows, maybe, law enforcement officers have a quarterly plan for terrorists has not yet made!

We hope that you will succeed.

Then we bite off too much wire cutters.

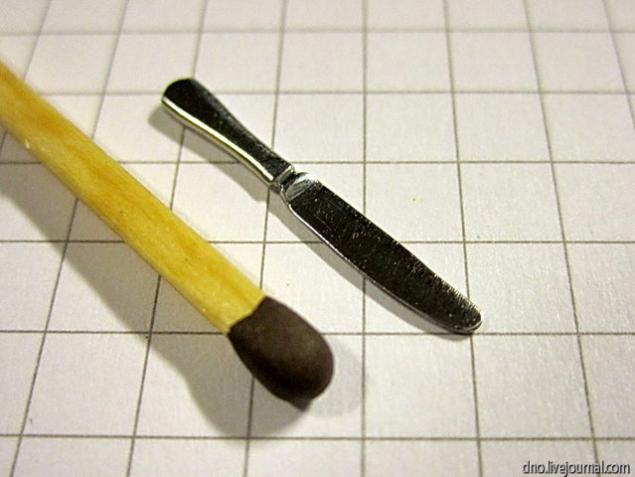

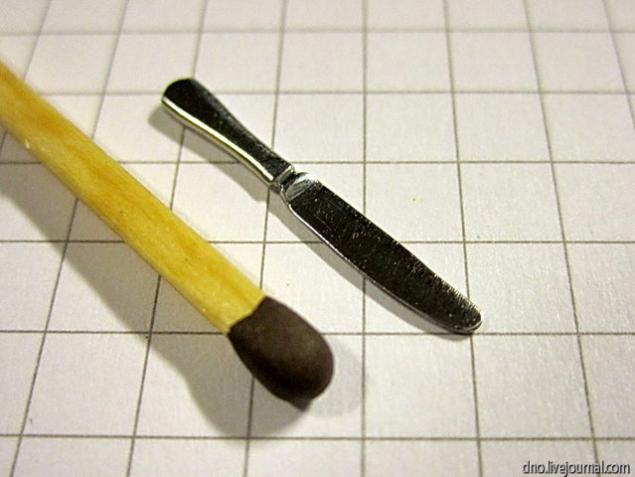

Process the nail file.

Any irregularities grind semicircular needle files, and flatness - flat.

Grind ...

The resulting semi-finished skins of fine sandpaper and polish.

Carefully ...

Nail bites nafig!

Further professional polishers I ask to make a sound so loud and beginning to tell how in the home manufacture buff, using a drill which can be engaged in bringing to the light lost its former beauty of things. Please note when selecting an object for experimentation keep in mind - his grandfather's teeth can not shine, and the cane he had not only to halt but also to wave it over his head as he ran. Here you are, I suppose, about the game of "small town" - not everyone has heard, and he may, at the time the court was the champion!

For the manufacture of polishing disk, we need a screw or a bolt with M6 or M8, two corresponding nuts, two washers and grandfather piece of felt boots.

From felt cut out several circles with a diameter of 55 mm at the center of which is to pick out a hole the diameter of the bolt. Then we collect everything as shown in the photo, grease paste GOI and drive forward to a bright future.

Drill at work must be rigidly clamped in a stand, a vice or on a footrest.

And here's the result! Children will be the Radio and doll, too !!!

Source:

Samodelnichal dno, he's fun, and Fota kamentah!

On completion of the process will be announced !!!

Nail, in turn, the subject of seemingly simple, narrow section proletarian destination. Tear-off calendar, a colander or on his jersey hanging in vintage interior - the most it.

When boiling perturbed mind, the nail can be used as a stylus, writing out on the hood of a neighbor wishes indicating direction, which knows no navigator in the world. But the most important thing when dealing with a nail, it does not give him good to get into children's hands.

In this case, the scope of the nail in the household repeatedly expands and unpredictably. From burying it in a flower pot or a pan of porridge before drawing it on a laptop, walls and lacquered furniture. It goes tools and creative leisure in free time, conveniently stored in my father's mother's shoe or boot, and even better - in the drum of a new washing machine.

Personally, after meeting with the screwdriver, a nail look with disdain on the rocker arm or torch, but a strategic reserve of rusty nails in case of economic or spiritual crisis, have and keep in the closet next to the spinning wheel and bast shoes.

Frankly, from a nail can make a lot of useful things in the economy, for example - "bullet" for the slingshot. But this I tell you I can not. I've got a blog peaceful and correctly made a slingshot if not handled properly - a serious thing, by the way!

Another thing, if from a nail to make such a harmless thing like a knife.

"In short, Sklifosovsky!" - I hear the cheers of those who have read this far and, therefore, turn to the topic of the post.

Now I'll tell you how to convert home nail diameter of 2, 5 mm in a simple table knife on a scale of 1 to 12.

For a start, it is necessary to flatten the end of the nail (that you can not do, but then the description of the manufacturing process will be reduced to the phrase "a nail with a file handle," which, as regular readers realize, not our method).

Search light the way - this is for mountain climbers and astronauts. We are wading into the kitchen under the cover of night in hopes to catch a refrigerator surprise risk at every step to meet the competition.

So, what am I doing? So, to flatten the end of the nail length of about 1, 5 cm, we need a hammer and anvil. When anvil you home for some reason was not possible to use, for example, a rail. If suddenly your rail first, nailed to the sleepers, and secondly, for it periodically pass commodity and passenger trains, keep in mind that walking near railroad tracks with a hammer in one hand and nail to another can result in confiscation of not only the above objects production threat to the world community, but also yourself.

Do not forget that the relevant authorities are not heard touching stories like the story about the knife from a nail, and even a link to this record does not relieve you of the passage forcibly mental examination.

In any case, better a little medical treatment, and then who knows, maybe, law enforcement officers have a quarterly plan for terrorists has not yet made!

We hope that you will succeed.

Then we bite off too much wire cutters.

Process the nail file.

Any irregularities grind semicircular needle files, and flatness - flat.

Grind ...

The resulting semi-finished skins of fine sandpaper and polish.

Carefully ...

Nail bites nafig!

Further professional polishers I ask to make a sound so loud and beginning to tell how in the home manufacture buff, using a drill which can be engaged in bringing to the light lost its former beauty of things. Please note when selecting an object for experimentation keep in mind - his grandfather's teeth can not shine, and the cane he had not only to halt but also to wave it over his head as he ran. Here you are, I suppose, about the game of "small town" - not everyone has heard, and he may, at the time the court was the champion!

For the manufacture of polishing disk, we need a screw or a bolt with M6 or M8, two corresponding nuts, two washers and grandfather piece of felt boots.

From felt cut out several circles with a diameter of 55 mm at the center of which is to pick out a hole the diameter of the bolt. Then we collect everything as shown in the photo, grease paste GOI and drive forward to a bright future.

Drill at work must be rigidly clamped in a stand, a vice or on a footrest.

And here's the result! Children will be the Radio and doll, too !!!

Source:

Tags

See also

10 amazing ideas that brought millions of

The mother of all folding knives

Mother folding knives

Vocational chocolate

The big idea for a small computer desk

10 tricks for quick cleaning in the nursery: the order is guaranteed!

Now I know how to decorate a festive table! 15 fabulous ideas for New Year's decor.